Maintenance – AERCO BMK 1.5 LN Dual Fuel June 2010 User Manual

Page 61

MAINTENANCE

7-5

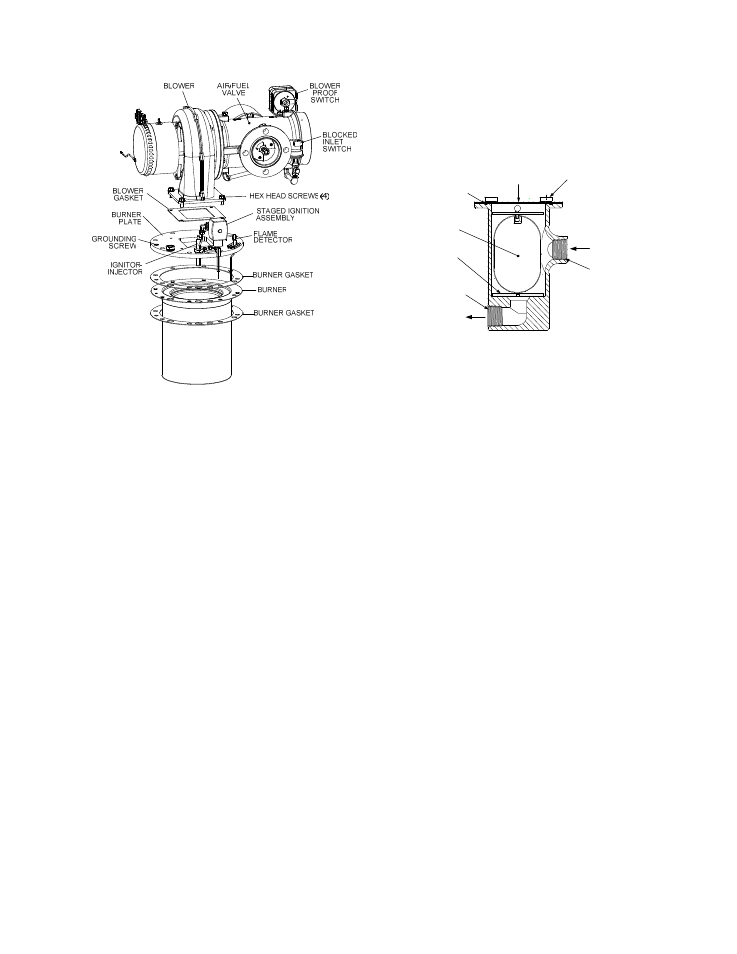

Figure 7-4

Burner Assembly Exploded View

7.7 CONDENSATE DRAIN TRAP

The Benchmark 1.5 Boiler contains a

condensate trap as shown in Chapter 2, Figure

2-5. The trap is located external to the unit and

attached to the drain pipe from the exhaust

manifold. This trap should be inspected and, if

necessary, cleaned to ensure proper operation.

To inspect and clean the trap, proceed as

follows:

1. Disconnect the external condensate trap by

loosening the union pipe connection

between the trap and the exhaust manifold

drain pipe.

2. Remove the connections on the inlet and

outlet sides of the condensate trap shown in

Figure 7-5.

3. Loosen the four (4) thumbscrews securing

the cover on the condensate trap. Remove

the cover.

4. Remove the float from the condensate trap.

5. Remove the orifice gasket from the trap.

6. Thoroughly clean the trap, float and gasket.

Also inspect the drain piping for blockage. If

the trap cannot be thoroughly cleaned,

replace the trap.

7. After the above items have been inspected

and thoroughly cleaned, replace the orifice

gasket and float in the condensate trap and

replace the trap cover.

8. Reassemble all piping and hose connections

to the condensate trap inlet and outlet.

Reconnect trap to exhaust manifold drain.

FLOAT

THUMB

SCREWS

(4)

3/4 NPT

PORT

INLET

OUTLET

3/4 NPT

PORT

COVER

O-RING

GASKET

ORIFICE

GASKET

Figure 7-5

External Condensate Trap

7.8 SHUTTING THE BOILER DOWN FOR

AN EXTENDED PERIOD OF TIME

If the boiler is to be taken out of service for an

extended period of time (one year or more), the

following instructions must be followed.

1. Set

ON/OFF switch on the front panel to the

OFF position to shut down the boiler’s

operating controls.

2. Disconnect AC power from the unit.

3. Close the water supply and return valves to

isolate boiler.

4. Close external gas supply valve.

5. Open relief valve to vent water pressure.

7.9 PLACING THE BOILER BACK IN

SERVICE AFTER A PROLONGED

SHUTDOWN

After a prolonged shutdown (one year or more),

the following procedures must be followed:

1. Review installation requirements included in

Chapter 2.

2. Inspect all piping and connections to the

unit.

3. Inspect exhaust vent, air duct (if applicable).

4. Perform initial startup per Chapter 4.

5. Perform safety device testing and scheduled

maintenance procedures per Chapters 6

and 7 of this manual.