Common specifications, Checklist, Sl-v-im-e – KEYENCE SL-V Series User Manual

Page 9

9

SL-V-IM-E

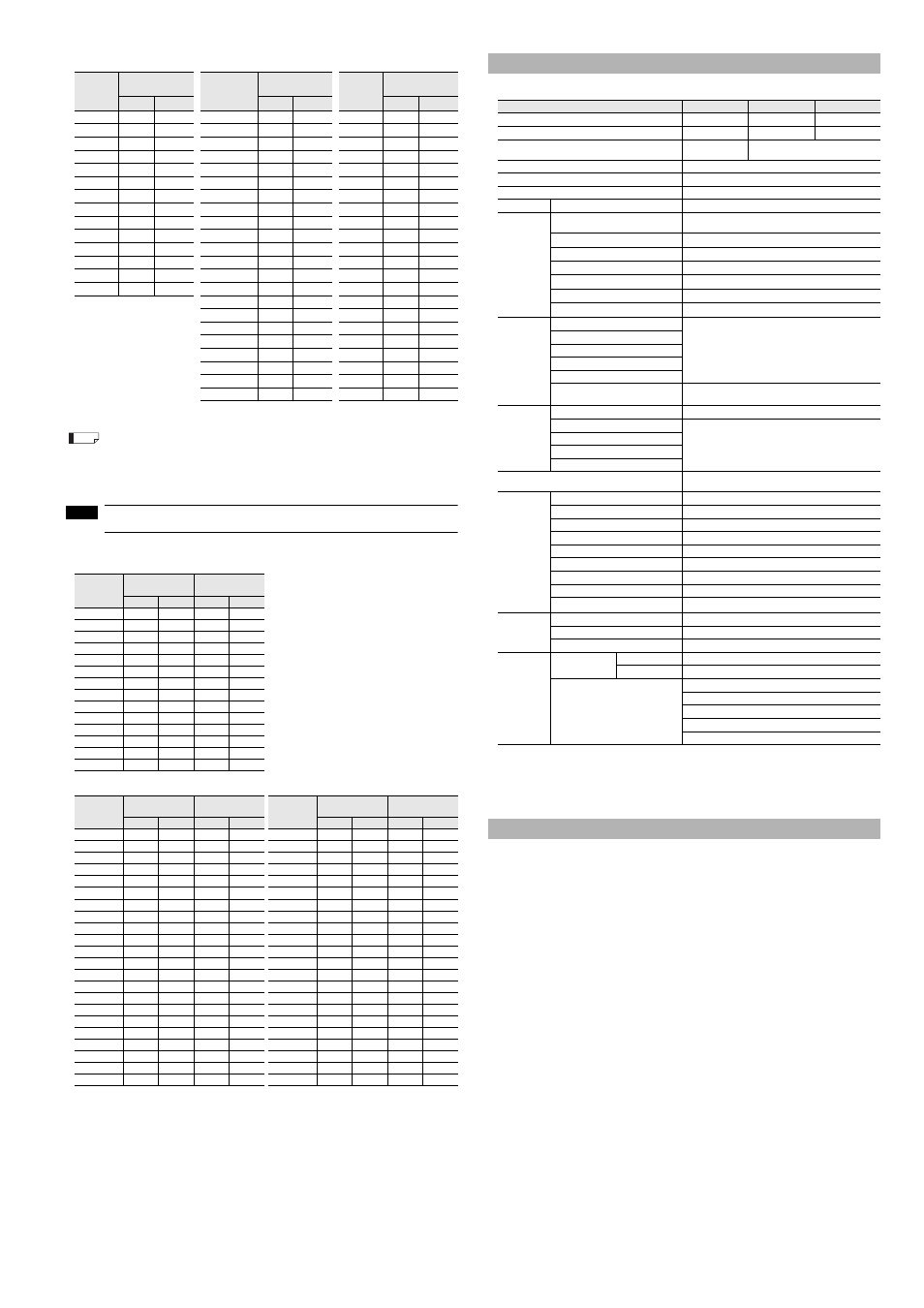

Response time

Units: ms

Units: ms

Units: ms

*1 If the interruption is present in the detection zone for less than 80 ms, the response time (OFF to ON) is to be 80ms or

more to ensure that the OSSD keeps OFF state for more than 80 ms.

When connecting the SL-V units in series, the response time (ON to OFF) is the sum of the response

times of all the individual SL-V units.

When connecting the SL-V32H (32 beam axes), SL-V24H (24 beam axes), and SL-V12L (12 beam

axes) in series, the response time of each unit is 10.3 ms, 9.2 ms, and 7.6 ms respectively, and the

response time (ON to OFF) is 10.3 ms + 9.2 ms + 7.6 ms = 27.1 ms.

the response time (OFF to ON) is 27.1 ms + 40ms = 67.1 ms.

1.6 m/s is the maximum speed of movement of the test piece to which the detection capability is maintained.

Current consumption

Unit: mA

Unit: mA

Unit: mA

*1

When the SL-V is used under surrounding air temperatures between 45 to 55

°C, the Maximum load current should not

exceed 300 mA.

*2

Applies to situations when power is either off or disconnected.

*3

The wiring resistance between the OSSD output and the connected equipment (excluding the resistance of the cable)

must be 2.5 ohms or less to ensure operation. If the cable length is 15 m or more and the load’s current consumption is

200 mA or more, the wire resistance must be 1 ohm or less.

*4

When operating in surrounding air temperatures ranging from 45 to 55

°C, use incandescent lamps (24 VDC, 1 to 3 W)

or LED lamps (load current:10 to 100 mA)

You are fully responsible for performing the risk assessment on your machine application, taking into

account performing maintenance and inspections, which are critical factor for appropriate risk

assessment. In addition, it is a responsibility for the responsible personnel to train the machine oper-

ators regarding inspection and maintenance of the machine and the SL-V.

Inspection before operation (Initial inspection)

When the installation of the SL-V is completed, the responsible personnel must verify the operation of

the SL-V in accordance with the checklist shown below. Note that the following inspection items com-

prise only a bare minimum inspection. KEYENCE Corporation strongly recommends including the nec-

essary checking items into this checklist based on the judgment of the responsible personnel since

additional criteria may be necessary depending on both the machine to which the SL-V is installed and

the laws, rules, regulations and standards in the country or region in which the SL-V is used/installed.

(1) Pre-check for installation condition

•

The machine under SL-V control can be caused to stop running by the OFF-state of OSSD.

•

The SL-V is installed so that the machine operator cannot go into or approach the hazardous area

without passing through the detection zone.

•

The interlock reset mechanism is installed so that it cannot be operated if there are any personnel

within the hazardous area.

•

The device to activate the override is installed so that it cannot be operated if there are any per-

sonnel within the hazardous area.

•

The SL-V has been installed at a distance greater than or equal to the minimum safety distance required.

•

If there are glossy surfaces nearby, move them so that they are beyond the minimum installation

distance according to "Installation Distance From Glossy Surfaces".

•

The SL-V is installed at a location free from light interference, for example fluorescent lamps.

•

The transmitters and receivers are paired correctly.

•

The beam axis spacing (detection capability) is the same between the transmitter and the

receiver when installing the SL-V.

•

The muting devices fulfill the conditions specified in this instruction manual and the requirements of the laws,

rules, regulations and standards in the country or region in which the SL-V and those devices are used.

•

The devices used to activate the override fulfill the conditions specified in this manual and

requirements of the laws, rules, regulations and standards in the country or region in which the

SL-V and those devices are used.

Model

Response time

(OSSD)

Model

Response time

(OSSD)

Model

Response time

(OSSD)

ON to OFF OFF to ON

*1

ON to OFF OFF to ON

*1

ON to OFF OFF to ON

*1

SL-V23F/FM

9.1

49.1

SL-V08H

7

47

SL-V04L

6.5

46.5

SL-V31F/FM

10.2

50.2

SL-V12H/HM

7.6

47.6

SL-V06L/LM

6.8

46.8

SL-V39F/FM

11.3

51.3

SL-V16H/HM

8.1

48.1

SL-V08L/LM

7

47

SL-V47F/FM

12.4

52.4

SL-V20H/HM

8.7

48.7

SL-V10L/LM

7.3

47.3

SL-V55F/FM

13.5

53.5

SL-V24H/HM

9.2

49.2

SL-V12L/LM

7.6

47.6

SL-V63F/FM

14.6

54.6

SL-V28H/HM

9.8

49.8

SL-V14L/LM

7.8

47.8

SL-V71F/FM

15.7

55.7

SL-V32H/HM

10.3

50.3

SL-V16L/LM

8.1

48.1

SL-V79F/FM

16.8

56.8

SL-V36H/HM

10.9

50.9

SL-V18L/LM

8.4

48.4

SL-V87F/FM

17.9

57.9

SL-V40H/HM

11.4

51.4

SL-V20L/LM

8.7

48.7

SL-V95F/FM

19

59

SL-V44H/HM

12

52

SL-V22L/LM

8.9

48.9

SL-V103F/FM

20.1

60.1

SL-V48H/HM

12.5

52.5

SL-V24L/LM

9.2

49.2

SL-V111F/FM

21.2

61.2

SL-V52H/HM

13.1

53.1

SL-V26L/LM

9.5

49.5

SL-V119F/FM

22.3

62.3

SL-V56H/HM

13.6

53.6

SL-V28L/LM

9.8

49.8

SL-V127F/FM

23.4

63.4

SL-V60H/HM

14.2

54.2

SL-V30L/LM

10

50

SL-V64H/HM

14.7

54.7

SL-V32L/LM

10.3

50.3

SL-V72H/HM

15.8

55.8

SL-V36L/LM

10.9

50.9

SL-V80H/HM

16.9

56.9

SL-V40L/LM

11.4

51.4

SL-V88H/HM

18

58

SL-V44L/LM

12

52

SL-V96H/HM

19.1

59.1

SL-V48L/LM

12.5

52.5

SL-V104H

20.2

60.2

SL-V52L

13.1

53.1

SL-V112H

21.3

61.3

SL-V56L

13.6

53.6

SL-V120H

22.4

62.4

SL-V60L

14.2

54.2

Model

When the center

indicator is ON

When the center

indicator is OFF

Transmitter

Receiver

Transmitter

Receiver

SL-V23F/FM

83

78

80

74

SL-V31F/FM

93

80

90

75

SL-V39F/FM

103

82

99

77

SL-V47F/FM

112

85

107

78

SL-V55F/FM

121

87

115

80

SL-V63F/FM

129

89

122

82

SL-V71F/FM

136

92

129

83

SL-V79F/FM

142

94

135

85

SL-V87F/FM

148

97

140

87

SL-V95F/FM

154

99

145

88

SL-V103F/FM

159

101

149

90

SL-V111F/FM

163

104

152

92

SL-V119F/FM

166

106

156

93

SL-V127F/FM

169

109

158

95

Model

When the center

indicator is ON

When the center

indicator is OFF

Model

When the center

indicator is ON

When the center

indicator is OFF

Transmitter

Receiver

Transmitter

Receiver

Transmitter

Receiver

Transmitter

Receiver

SL-V08H

56

70

52

65

SL-V04L

48

70

45

66

SL-V12H/HM

63

72

58

66

SL-V06L/LM

53

71

50

67

SL-V16H/HM

69

74

64

67

SL-V08L/LM

59

72

55

67

SL-V20H/HM

75

75

70

68

SL-V10L/LM

64

74

59

67

SL-V24H/HM

81

77

76

69

SL-V12L/LM

69

75

64

68

SL-V28H/HM

87

79

81

69

SL-V14L/LM

74

76

68

68

SL-V32H/HM

93

80

86

70

SL-V16L/LM

79

77

72

69

SL-V36H/HM

98

82

91

71

SL-V18L/LM

84

78

76

69

SL-V40H/HM

103

84

96

72

SL-V20L/LM

88

80

80

70

SL-V44H/HM

108

85

100

73

SL-V22L/LM

93

81

84

70

SL-V48H/HM

113

87

104

74

SL-V24L/LM

97

82

88

71

SL-V52H/HM

117

88

109

74

SL-V26L/LM

101

83

92

71

SL-V56H/HM

122

90

112

75

SL-V28L/LM

105

84

95

71

SL-V60H/HM

126

91

116

76

SL-V30L/LM

109

86

98

72

SL-V64H/HM

130

93

120

77

SL-V32L/LM

113

87

102

72

SL-V72H/HM

137

96

126

78

SL-V36L/LM

120

89

108

73

SL-V80H/HM

144

98

132

80

SL-V40L/LM

126

91

113

74

SL-V88H/HM

149

101

136

81

SL-V44L/LM

132

93

119

75

SL-V96H/HM

154

104

140

83

SL-V48L/LM

137

95

123

75

SL-V104H

159

107

143

84

SL-V52L

142

97

127

76

SL-V112H

162

109

146

86

SL-V56L

146

99

131

77

SL-V120H

165

112

147

87

SL-V60L

150

101

134

78

Reference

NOTE

Common specifications

Model

SL-VF/SL-VFM

SL-VH/SL-VHM

SL-VL/SL-VLM

Beam axis spacing/Lens diameter

10 mm/

φ4 mm

20 mm/

φ5 mm

40 mm/

φ5 mm

Detection capability

φ14 mm

φ25 mm

φ45 mm

Operating distance

0.1m to 7.0m

0.1m to 9.0m (detection height of 1,260mm or less)

0.1m to 7.0m (detection height of 1,400mm or more)

Effective aperture angle

Max. ±2.5

° (When operating distance is 3 m (9.84 ft.) or more)

Light source

Infrared LED (850 nm)

Operation form

Turns on when no interruptions are present in the detection zone

Rating

Power voltage

24 VDC +10%, -20% (Ripple P-P 10% or less), Class 2

OSSD

Output

2 outputs each for PNP and NPN.

Can be changed by using the connector cable

Max. load current

500 mA

*1

Residual voltage (during ON)

Max. 2.5 V (with a cable length of 7 m (22.97 ft.))

OFF state voltage

Max. 2.0 V (with a cable length of 7 m (22.97 ft.))

Leakage current

Max. 100

μA

*2

Max. capacitive load

1

μF (with a load resistance of 100 Ω)

Load wiring resistance

Max. 2.5

Ω

*3

Non safety-

related output

AUX

Output with automatic PNP/NPN switching function, 50 mA

max.

Interlock-reset-ready output

Alert output

Clear/Blocked Output

State information output 1, 2

Muting lamp output

Incandescent lamp (24 VDC, 1 to 7 W) or LED lamp

(load current :10 to 300 mA)

*4

can be connected

Input

EDM input

Short-circuit current 10 mA

Wait input

Short-circuit current 2.5 mA

Reset input

Muting input 1, 2

Override input

Protection circuit

Reverse current protection, short-circuit protection for each

output, surge protection for each output

Environmental

condition

Enclosure protection

IP65 (IEC60529), IP65/67 (only for SL-VFM,SL-VHM and SL-VLM)

Overvoltage Category

II

Operating ambient temperature

-10 to +55

°C (No freezing)

Storage ambient temperature

-25 to +60

°C (No freezing)

Operating relative humidity

15% to 85%RH (No condensation)

Storage relative humidity

15% to 95%RH

Surrounding light

Incandescent lamp: 5,000 lx or less. Sunlight: 20,000 lx or less

Vibration

10 to 55 Hz, 0.7 mm compound amplitude, 20 sweeps each in X, Y, and Z directions

Shock

100 m/s

2

(Approx. 10 G) 16 ms pulse, in X, Y, Z directions 1,000 times each axis

Material

Main unit case

Aluminum

Upper case/Lower case

Zinc die-cast

Front cover

Polycarbonate, SUS304

Approved

standards

EMC

EMS

IEC61496-1, EN61496-1, UL61496-1

EMI

EN55011 ClassA, FCC Part15B ClassA, ICES-003 Class A

Safety

IEC61496-1, EN61496-1, UL61496-1 (Type 4 ESPE)

IEC61496-2, UL61496-2, EN61496-2 (Type 4 AOPD)

IEC61508, EN61508 (SIL3), IEC62061, EN62061 (SIL3)

EN ISO13849-1:2008 (Category 4, PL e)

UL508, UL1998

Checklist