Using mounting bracket f, Connecting the sensor head connection cable, Installing the air tube (gt2-pa12k/pa12) – KEYENCE GT2-PA12K/PA12 User Manual

Page 2: Compatible air tubes, How to attach/detach the air tube, Supplying air, Notice

2

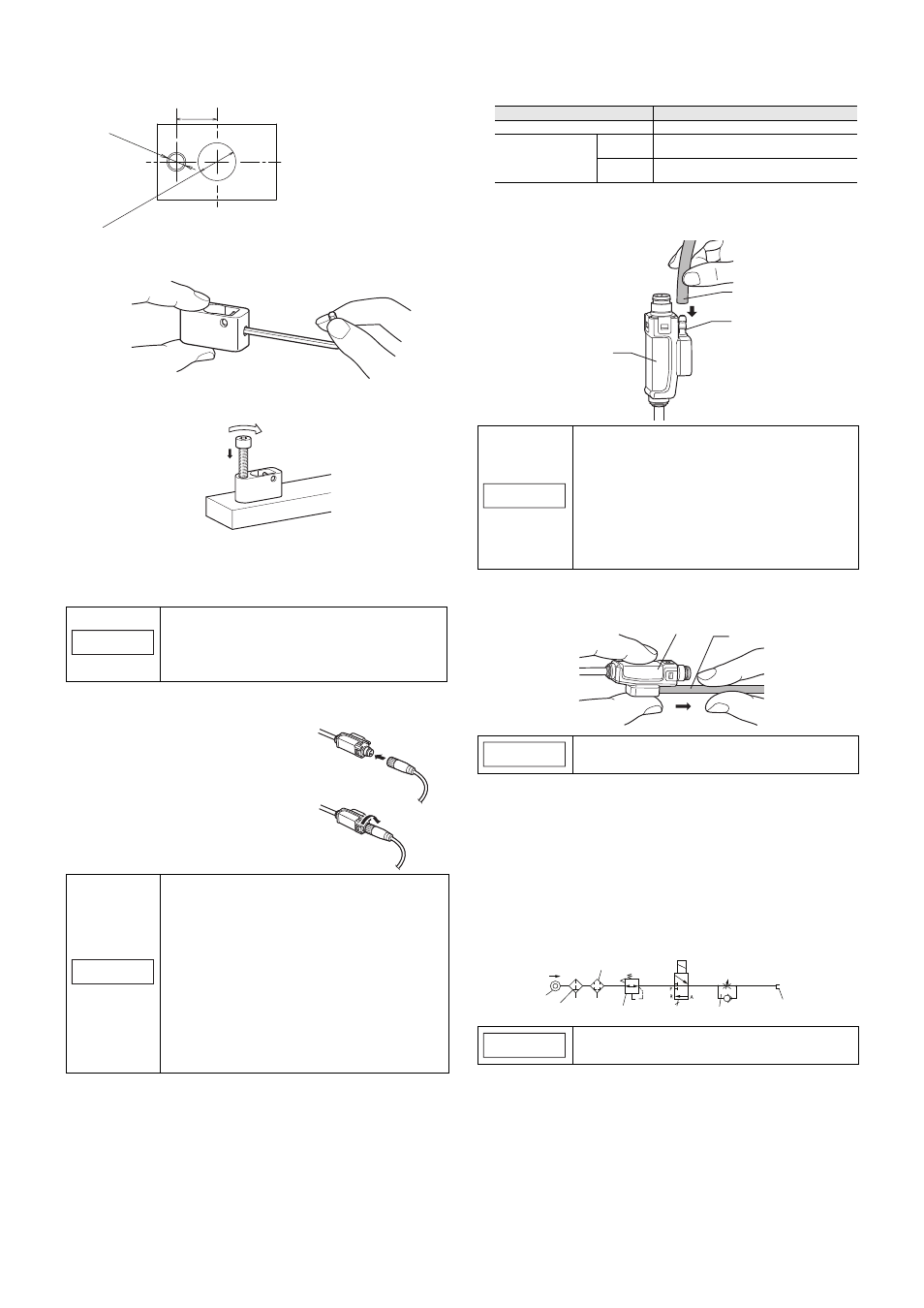

Using mounting bracket F

1

Refer to the illustration below, and cut the jig to create a sensor head

mounting hole.

2

Loosen the screw on the side of mounting bracket F using the

supplied hexagonal wrench.

3

Align mounting bracket F with the hole made in step 1 and secure it

using the supplied hexagonal wrench.

4

Insert the sensor head, and tighten the screw loosened in step 2

using the supplied hexagonal wrench to secure. The recommended

tightening torque is 0.6 to 0.8 N•m. Make sure that the dust boot does

not obstruct the metal plating that mounting bracket F is attached to.

Connecting the sensor head connection cable

1

Insert the sensor head connection cable

into the cable connector on the relay con-

nector cable.

2

Secure the connector with the sensor

head connecting cable screw.

Installing the air tube (GT2-PA12K/PA12)

Compatible air tubes

Use a tube with the following specifications.

How to attach/detach the air tube

• Attaching the air tube

Insert the air tube into the air supply hole on the relay amplifier.

• Detaching the air tube

To detach the air tube, pull the air tube in the direction of the arrow, as

indicated in the figure below.

Supplying air

• Refer to the diagram below to create a pneumatic circuit.

• Use an air filter, mist separator, etc. to provide clean dry air. Empty the

drainage from the filter regularly, before it exceeds the specified line.

• Make sure that the air pressure of the supplied air is constant and in the

range of 0.24 to 0.26 MPa. Use a precision regulator to control the air

pressure. If the air pressure is below 0.24 MPa, the spindle may not

extend fully.

• When supplying air (with the spindle extended), up to 3L/min of air will be

emitted from the tip of the dust seal.

• The measuring ability of the device changes according to the air pressure

of the air supply. Refer to "Specifications" for details.

NOTICE

• When loosening the screw with the hexagonal

wrench, insert the long end of the hexagonal

wrench into the hex screw and rotate the small end

with your hand.

• Do not forcibly tighten the hex screw.

NOTICE

• When connecting the connector, be sure to insert it

straight, and tighten it securely. (Recommended

tightening torque: 0.4 to 0.5 N•m

*

)

If the connection is not tight enough, the connector

may be loosened by vibration or other causes,

leading to a connection failure.

(* After tightening it strongly by hand, use pliers or

other tools to rotate it about 30° for further

tightening.)

• When the head is attached to a moving part, and the

cable will be repeatedly bent, ensure that the cable

between the sensor head and relay connector does

not bend. Instead, bend the sensor head cable

connecting the relay connector and the amplifier.

8.5

8

+0

.20

0

+0

.00

5

M4 x 0

.7

Make sure that the metal plating

mounting bracket F attaches to is at

least 5 mm thick.

Item

Description

Recommended tubing material

Urethane

Tubing size

Outer

diameter

4 mm

Inner

diameter

2.5 mm

NOTICE

• For best results, cut the end of the tube at a right

angle, ensure that the outer perimeter is not

damaged, and that it still maintains a circular cross

section.

• If the tube is not properly inserted, air leakage may

result.

• After attaching, pull on the tube to make sure it is

secure.

• Use a urethane tube. Make sure it also has a

bending radius of at least 50 mm.

NOTICE

Before detaching the tube, be sure to stop any air

flow.

NOTICE

If the air supply pressure exceeds 0.5 MPa, the sensor

head may become damaged.

Air tube

Air supply hole

Relay connector

Relay connector

Air tube

Mist separator

Air filter

Pressure

source

AIR

Solenoid valve

Precision regulator

Air supply part

GT2-PA12K/PA12

Speed controller