Specifications, Safety precautions – KEYENCE FU-95(HZ) User Manual

Page 2

2

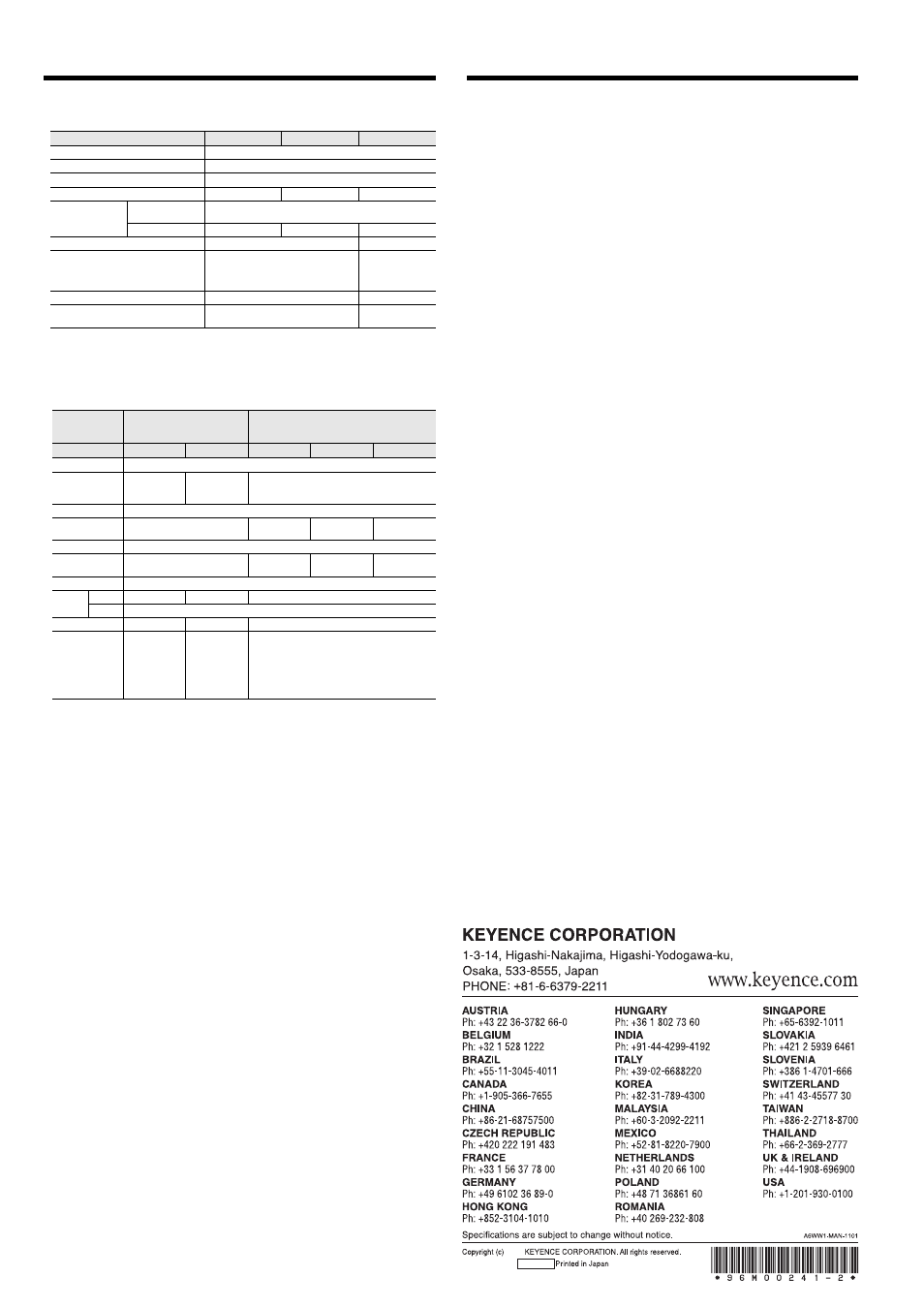

Specifications

■

Liquid-contacting (fluorocarbon polymer) type

*1 No freezing

*2 Hydrofluoric acid cannot be used in detection.

Detection also cannot be performed with some liquids, such as those with a milky-white color.

■

Pipe mounting type

*1 The recommended pipe wall thickness is 1 mm (when using the FS-V10/V20/V30 Series).

*2 No freezing.

*3 Detection cannot be performed with some liquids, such as those with a milky-white color.

*4 When normally used under high temperatures, the recommended ambient temperature is 90

C

max.

*5 FU-95HA uses fluorocarbon polymer coating.

*6 OP-82177 for FU-95W [cable tie (W4.8 x H1.3 x L445) x 2, nonslip rubber tube x 2] is sold sepa-

rately and is compatible with pipe diameters from

26 to 80 mm.

Safety Precautions

■

Precautions for sensitivity adjustment

Common

• As noted above, when the liquid level detection sensor is used to detect water or another type of

colorless, clear liquid, the detection principles state that the received light intensity is higher when

there is no liquid and lower when there is liquid (during contact with a liquid).

• If the liquid has a milky-white color or another highly reflective color, the received light intensity

increases when there is liquid, which may reduce the sensitivity in terms of detecting the presence

of a liquid.

• If chattering occurs due to problems such as bubbles or dripping, use a timer to delay detection.

• If there are concerns about fluctuations of the displayed value when using a digital display ampli-

fier, use the scaling function on the FS-V30 Series amplifier unit.

■

Precautions about mounting

Liquid-contacting type FU-93(Z)/94C

• A thermal expansion tube is inserted 80 mm from the end in order to secure the sensor section and

the fluorocarbon polymer tube. Bending or cutting this area will cause the rigid properties to

weaken.

• Do not pull or apply excessive force to the fiber cable. Keep pulling to a maximum of 30 N

3sec.

• Clean before use according to the operating environment.

• If means are needed to differentiate between FU-93 and FU-93Z, attach the silicon tube that comes

with FU-93Z to the fiber cable.

Pipe mounting type FU-95(Z/HA/S/W)

• Detection may not be possible when using a pipe with thick walls (3 mm or higher).

• Opaque pipes cannot be used.

• Do not pull or apply excessive force to the fiber cable. Keep pulling to a maximum of 10 N

3sec.

■

Precautions for liquid level detection

Liquid-contacting type FU-93(Z)/94C

• Stable detection may not be possible when using one of the following liquids.

When bubbles are attached to the sensor tip

When liquid drips onto the sensor tip during a period of no liquid contact or when liquid is

attached to the sensor tip

Liquids with highly reflective color, such as milky-white

Liquids that stain the fluorocarbon polymer coating, such as high temperature oil

• Hydrofluoric acid or high temperature substances such as acids, alkali, or vapors can pass

through the fluorocarbon polymer coating, corrode the internal fibers, and lead to damage or a

reduction in sensitivity.

• When used under high temperatures, the fluorocarbon polymer becomes a maximum of 3% of the

total length longer. Take this into consideration when determining the mounting position.

Pipe mounting type FU-95(Z/HA/S/W)

• Stable detection may not be possible when using one of the following liquids.

When bubbles occur in the pipe

When dripping occurs on the inside of the pipe walls

Liquids that stain the transparent tube

• The 16 optical axis type is less affected by bubbles and dripping than the single optical axis type.

Model

FU-93

FU-93Z

FU-94C

Detection target

Liquid

*2

Repeatability

1 mm max. (for water)

Pressure resistance

-49 kPa to 490 kPa

Ambient temperature

*1

-40 to +70

C

-40 to +50

C

-40 to +200

C

Minimum bend

radius

Fluorocarbon

polymer section

R40 mm (Cannot be bent within 80 mm from the edge)

Fiber section

R25 mm

R0.5 mm

R25 mm

Fiber length

2 m (free-cut)

2 m

Fiber material

Plastic (fluorocarbon polymer coating)

Multicomponent glass

(Fluorocarbon polymer

coating, with SUS

protective tube)

Weight

Approx. 78 g

Approx. 90 g

Accessory

Fiber cutter x 1, Adapter A x 1

Model silicon tube (FU-93Z only) x 1

None

Type

Air bubble/dripping

countermeasures

(16 optical axes)

Compact (Single optical axis)

Model

FU-95S

FU-95W

FU-95Z

FU-95HA

FU-95

Detection target

Liquid

*3

Mounting

transparent

pipe diameter

*1

4 to 26 mm

26 mm min.

recommended

(No upper limit)

4 to 26 mm

Repeatability

1 mm max. (for water)

Ambient

temperature

*2

-40 to +70

C

-40 to +50

C

-40 to +105

C

*4

-40 to +70

C

Relative humidity

35 to 85% RH (No freezing)

Minimum bend

radius

R5 mm

R2 mm

R25 mm

R10 mm

Fiber length

2 m (free-cut)

Material

Main unit

Polyetherimide

PBT

Polysulfon

Fiber

Plastic (polyethylene coating

*5

)

Weight

Approx. 23 g

Approx. 20 g

Approx. 7 g

Accessory

Cable tie

(W2.5 x H1.1 x

L203) x 2

Nonslip rubber

tubes x 2

Fiber

Cutter x 1

Fiber

Cutter x 1

*6

Cable tie (W3.6 x H1.1 x L142) x 2,

Nonslip rubber tubes x 2, Spacer (

5 x 6) x 2,

Screw (M3 x 20) x 2, Hexagonal nut (M3) x 2,

Fiber cutter x 1, Adapter B x 1

2008

00241E 1112-2 96M00241