3 checking the gap width, Working with the laboratory jaw crusher – FRITSCH PULVERISETTE 1, Model I premium line User Manual

Page 30

9.

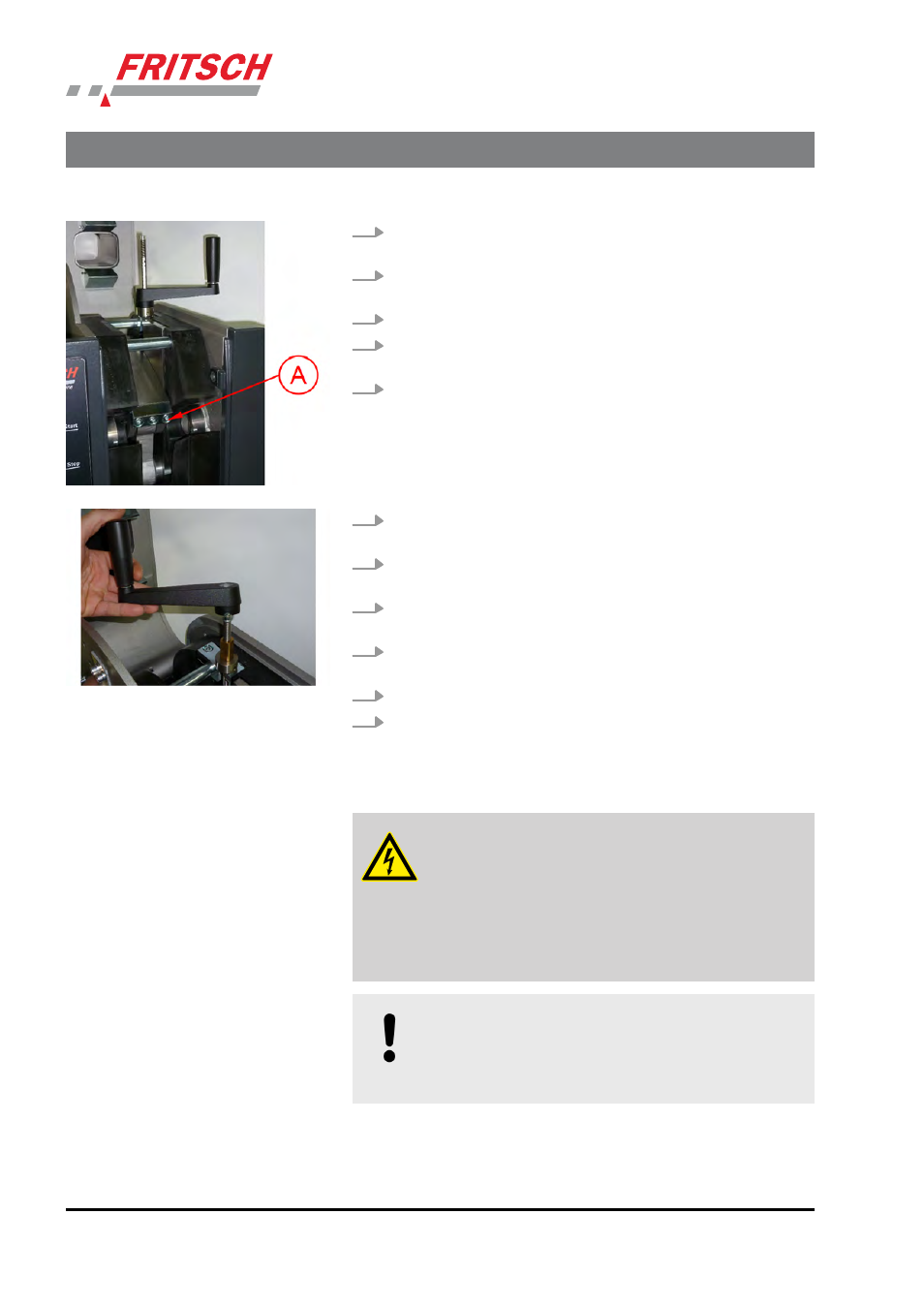

Turn the crank until the 3 cylinder-head screws (A) of the movable

crushing jaw (12) can be accessed.

10.

After undoing the 3 cylinder-head screws (A) with the hex wrench

(c), you can lift off the clamping strip (20).

11.

Take out the crushing plate (21).

12.

Clean all parts in order that the crushing plate has even contact

during the installation.

13.

Insert the replacement crushing plate or the old, turned crushing

plate (21) and screw the clamping strip (20) back on again.

14.

Then turn the crank to move the crushing jaw (12) back into the

lower position.

15.

Refit the guide pin (3). See also Ä Chapter 5.3.5 ‘Adjusting the

16.

Remove the crank (a) and re-attach the pull plate with the

threaded spindle (b) to the retaining lug.

17.

Re-install the crushing jaw (13). SeeÄ Chapter 5.2.1 ‘Replacing the

crushing plate (17) of the fixed crushing jaw (13)’ on page 26.

18.

Close the lid (7).

19.

Push in the source material container (8).

5.2.3 Checking the gap width

DANGER!

Mains voltage!

– Before beginning with maintenance and assembly

work, disconnect the mains plug and protect the device

against being unintentionally switched back on!

– Indicate maintenance and assembly work with warning

signs.

NOTICE!

During operation of the Jaw Crusher, the crushing plates

(17, 21) must not touch each other at the narrowest gap

width.

Working with the laboratory jaw crusher

- 30 -