Working with the laboratory jaw crusher – FRITSCH PULVERISETTE 1, Model I premium line User Manual

Page 25

Aluminium

1 pair of support walls

43.4040.13

POM

1 pair of support walls

43.4045.16

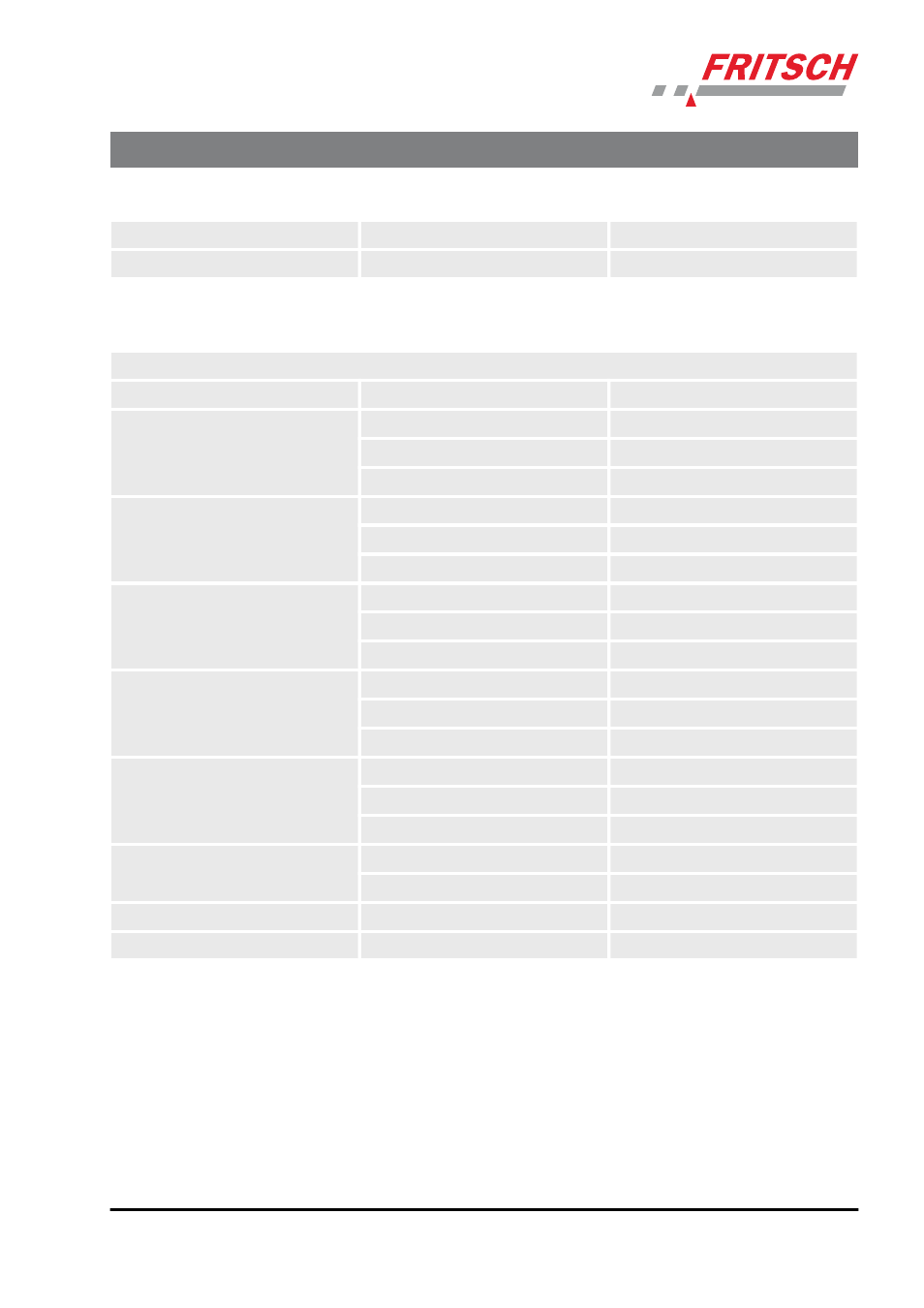

Model II

Material

Designation

Order number

Tempered tool steel

Fixed crushing plate

43.3010.09

Movable crushing plate

43.3020.09

1 pair of support walls

43.4000.09

Chromium-free steel

Fixed crushing plate

43.3011.09

Movable crushing plate

43.3021.09

1 pair of support walls

43.4010.09

Chromium-nickel stainless steel

Fixed crushing plate

43.3030.10

Movable crushing plate

43.3040.10

1 pair of support walls

43.4020.10

Tungsten carbide (WC + Co)

Fixed crushing plate

43.3050.08

Movable crushing plate

43.3060.08

1 pair of support walls

43.4030.08

Zirconium oxide

Fixed crushing plate

43.3100.27

Movable crushing plate

43.3110.27

1 pair of support walls

43.4050.27

Manganese steel

Fixed crushing plate

43.3130.23

Movable crushing plate

43.3140.23

Aluminium

1 pair of support walls

43.4040.13

POM

1 pair of support walls

43.4045.16

The crushing plates made of zirconium oxide are only suitable for

crushing medium-hard and brittle materials (or similar). Metal may not

be crushed under any circumstances.

The Cr-Ni steel equipment is recommended if damp material is crushed

and this would cause the plates and walls made of tool steel to rust.

The tungsten carbide equipment is recommended for crushing very hard

material or if ferrous contaminants are to be avoided.

Working with the laboratory jaw crusher

- 25 -