5 working with the laboratory jaw crusher, Ä chapter 5 ‘working with the, 5working with the laboratory jaw crusher – FRITSCH PULVERISETTE 1, Model I premium line User Manual

Page 24: Working with the laboratory jaw crusher

5

Working with the laboratory jaw crusher

NOTICE!

In the case of the Jaw Crusher with single-phase motor,

230V and 110V, a maximum of 20 switching operations per

hour are permitted!

5.1 Selecting the crushing plates and the lateral support walls

The standard version of the jaw crusher is equipped with crushing plates

(17, 21) and support walls (11) made of tempered tool steel.

As a special version or for retrofitting, crushing plates and

support walls can be delivered in the following materials:

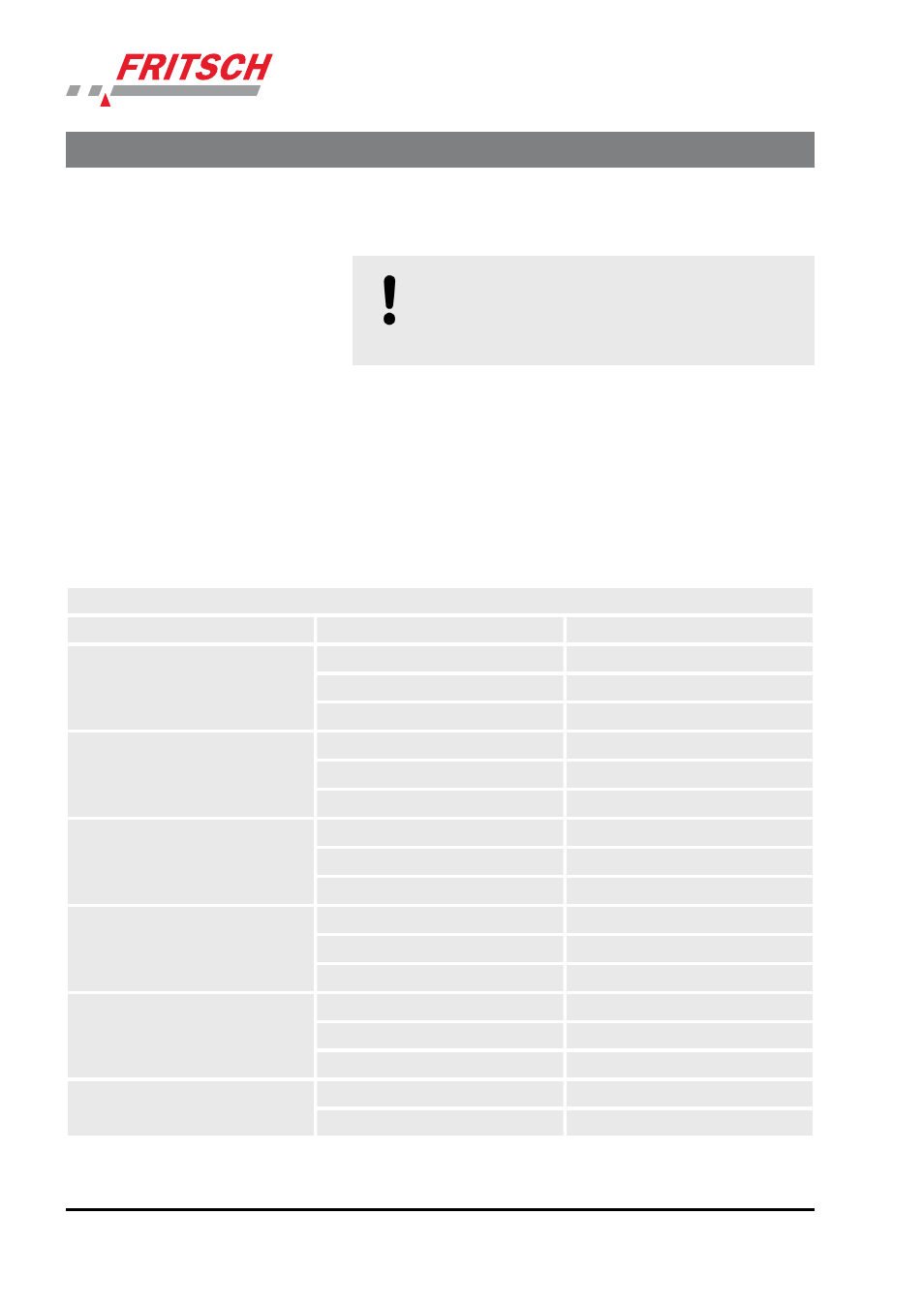

Model I

Material

Designation

Order number

Tempered tool steel

Fixed crushing plate

43.0010.09

Movable crushing plate

43.0020.09

1 pair of support walls

43.4000.09

Chromium-free steel

Fixed crushing plate

43.0011.09

Movable crushing plate

43.0021.09

1 pair of support walls

43.4010.09

Chromium-nickel stainless steel

Fixed crushing plate

43.0030.10

Movable crushing plate

43.0040.10

1 pair of support walls

43.4020.10

Tungsten carbide (WC + Co)

Fixed crushing plate

43.0050.08

Movable crushing plate

43.0060.08

1 pair of support walls

43.4030.08

Zirconium oxide

Fixed crushing plate

43.0100.27

Movable crushing plate

43.0110.27

1 pair of support walls

43.4050.27

Manganese steel

Fixed crushing plate

43.0130.23

Movable crushing plate

43.0140.23

Working with the laboratory jaw crusher

- 24 -