7 warranty, 8 troubleshooting checklist – FRITSCH PULVERISETTE 25 User Manual

Page 38

page 37

PULVERISETTE 25

7 Warranty

The warranty card enclosed with the device upon delivery must

be completely filled out and returned to the delivering factory so

that the warranty can enter into effect.

Online registration is also possible. More information can be

found on your warranty card or on our website

http://www.fritsch.de

The company Fritsch GmbH in Idar-Oberstein and your

"Technical Application Laboratory" or the corresponding national

representatives would be happy to provide you with advice and

assistance.

Please include the serial number given on the type plate along

with any questions. The type plate is located on the back of

instrument.

Please note that the original Fritsch packaging must be used

in the event that the machine is returned. Fritsch GmbH is

not responsible for damages resulting from improper

packaging (non-Fritsch packaging).

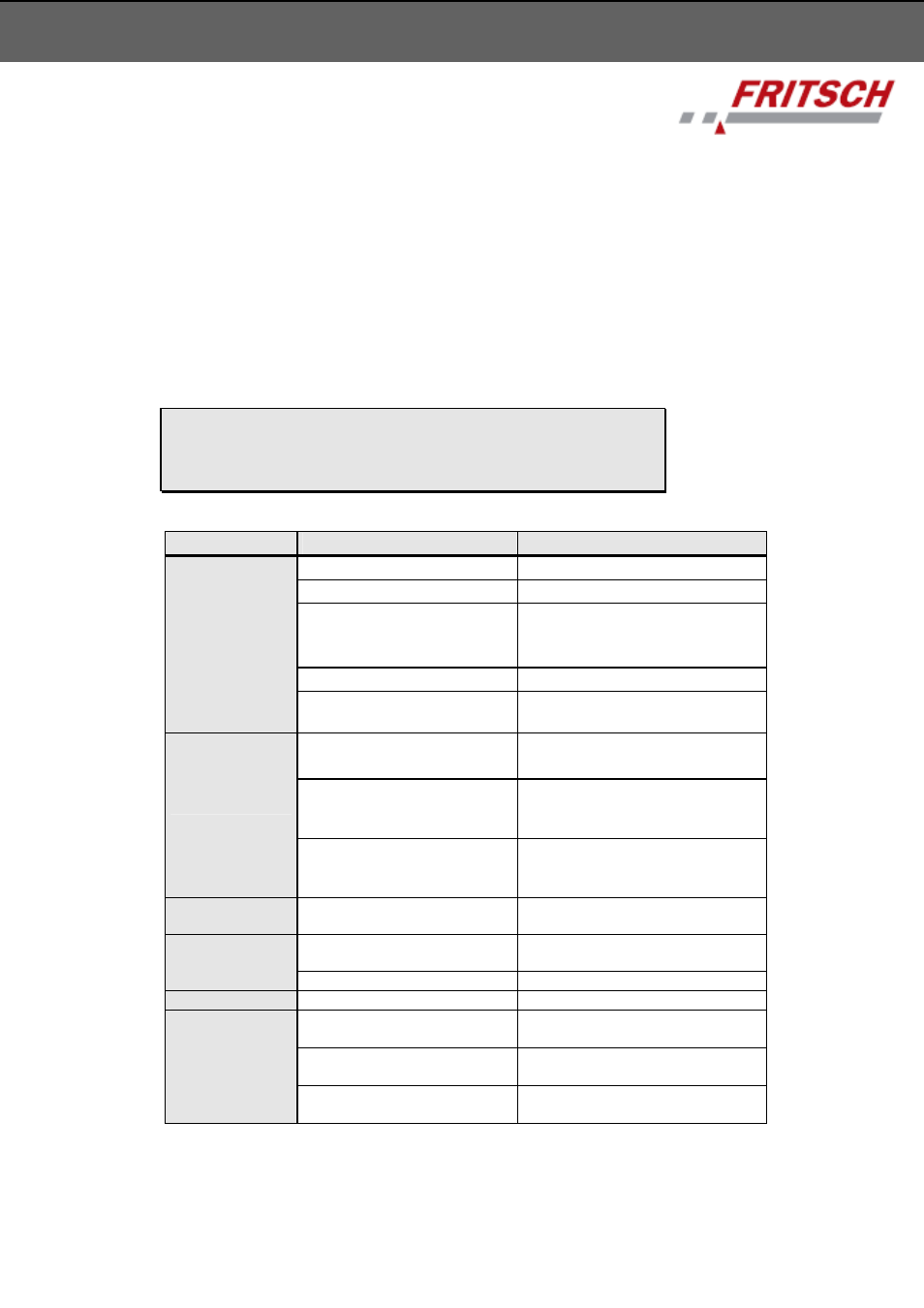

8 Troubleshooting

Checklist

Malfunction

Possible cause

Elimination of error

Not connected to mains

Plug in mains plug (20)

Main switch (19) at 0 (OFF)

Set the main switch (19) to I (ON).

In case of three-phase a.c.

motor:

Incorrect direction of rotation

Change two phases (chapter 3.6)

Circuit breaker of the building Press in the circuit breaker

The Start button

does not light

green.

Fuse burnt out

Remove the housing and replace

the fuse

Cover flap (6) not properly

closed

Clean the contact surface

Close the cover flap (6)

Collecting vessel (8) not

pushed in properly

Push in the collecting vessel

properly so that the safety switch

(15) engages

START button

pressed but

Mill does not

start up

Funnel lid (16) of the standard

funnel (1) not closed correctly

Close the funnel lid (16) correctly

Æ until the safety switch (17)

clicks into place

Mill does not

move

Motor protection switch has

tripped

Motor protection switch (see

chapter 4.4)

Rotational direction incorrect Swap two phases on the mains

plug (chapter 3.6)

STOP button

lights red

Too much grinding material

Reduce the input quantity

Material escapes

Material is extremely fine

x Rotor

imbalance

x Cones

contaminated

(Chapter

4.1.4)

x Bearing in cover flap (6)

defective

x Replace

bearing

Uneven running

with severe

vibration

x Parts broken off the rotor

(3)

x Parts broken off the rotor (3)

(chapter 4.1.4)

There is a copy of the circuit diagrams in the machine.