3 grinding process with the protected funnel – FRITSCH PULVERISETTE 25 User Manual

Page 30

page 29

PULVERISETTE 25

4.3 Grinding Process with the Protected Funnel

1. Set the main switch (19) on the back of the instrument to I (ON).

2. Close the cutting mill (see chapter 4.1.6).

3. Insert the collecting vessel (8).

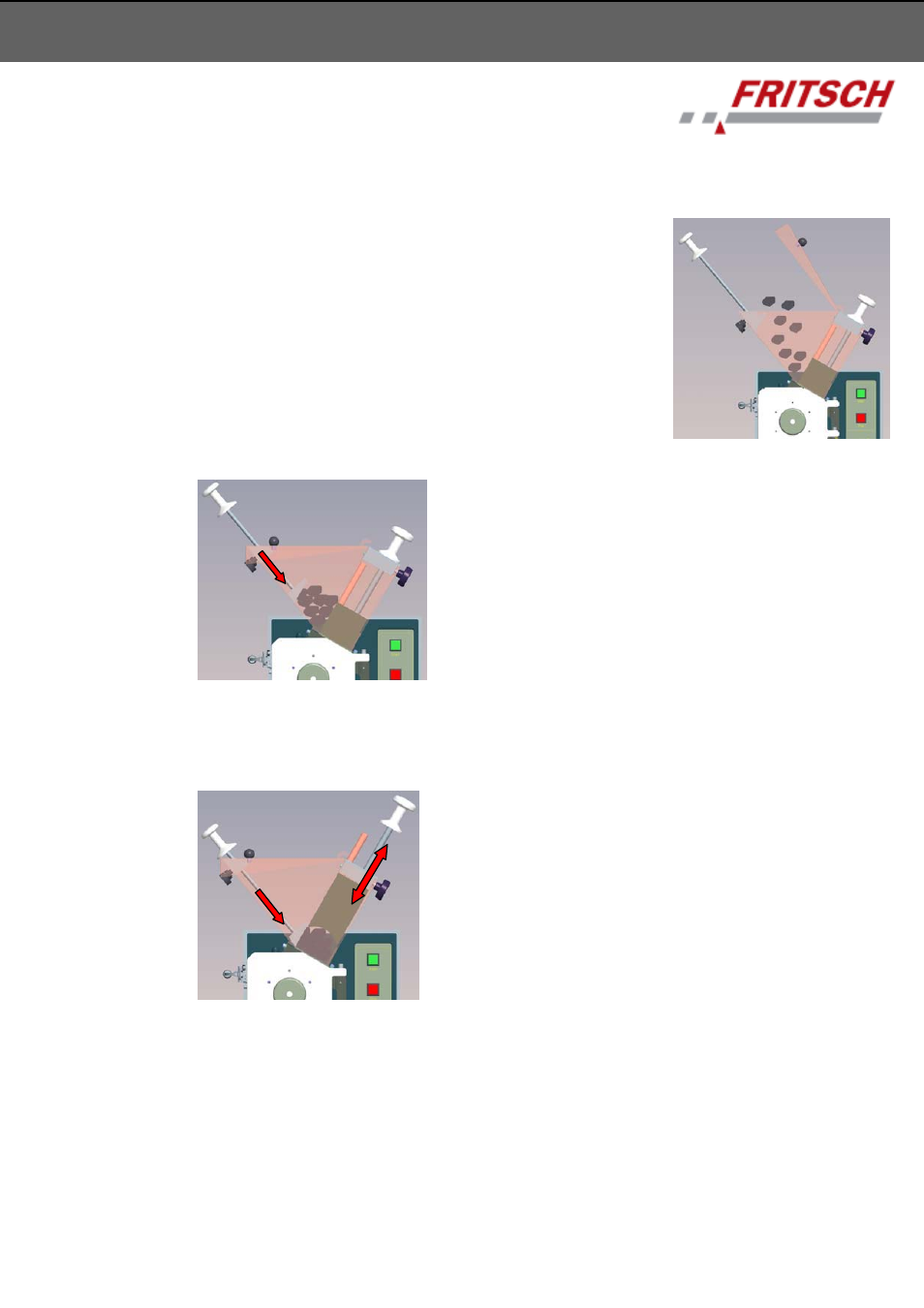

4. Pull out the sample pusher (24) fully.

5. Move the piston (23) into the lower position.

6. Open up the funnel lid (21), add some grinding material and

close the lid again.

The quantity of material to be ground will depend on the feed

grain size and the grindability of the material. It is best to start

with small quantities and increase the quantity depending on

the success of the grinding process.

7. Switch on the instrument

Æ Press the green Start button

(chapter 0).

8. Move the sample pusher (24) to the right in the direction of the

piston (23) until the material to be ground is in front of the

piston (23).

9. Pull the piston (23) upwards, and move the sample pusher

(24) to the right until the material to be ground drops into to

the grinding chamber (slight grinding noise will be heard).

10.Leave the sample pusher (24) at the right, and move the

piston (23) downwards (grinding noise will become louder).

11.Push the piston (23) up/down. This pumping results in air

being sucked in and pumped out by the air filter on the right-

hand side of the machine.

The air movement is critical to ensuring the fine material

passes through the sieve for collection while the larger

particles are returned for reprocessing.

12.The grinding operation is finished when the grinding noise

becomes quieter.

13.Further material to be ground can then loaded into the

machine as above.