Series 5000 – Cub Cadet 5000 Series User Manual

Page 22

Series 5000

18

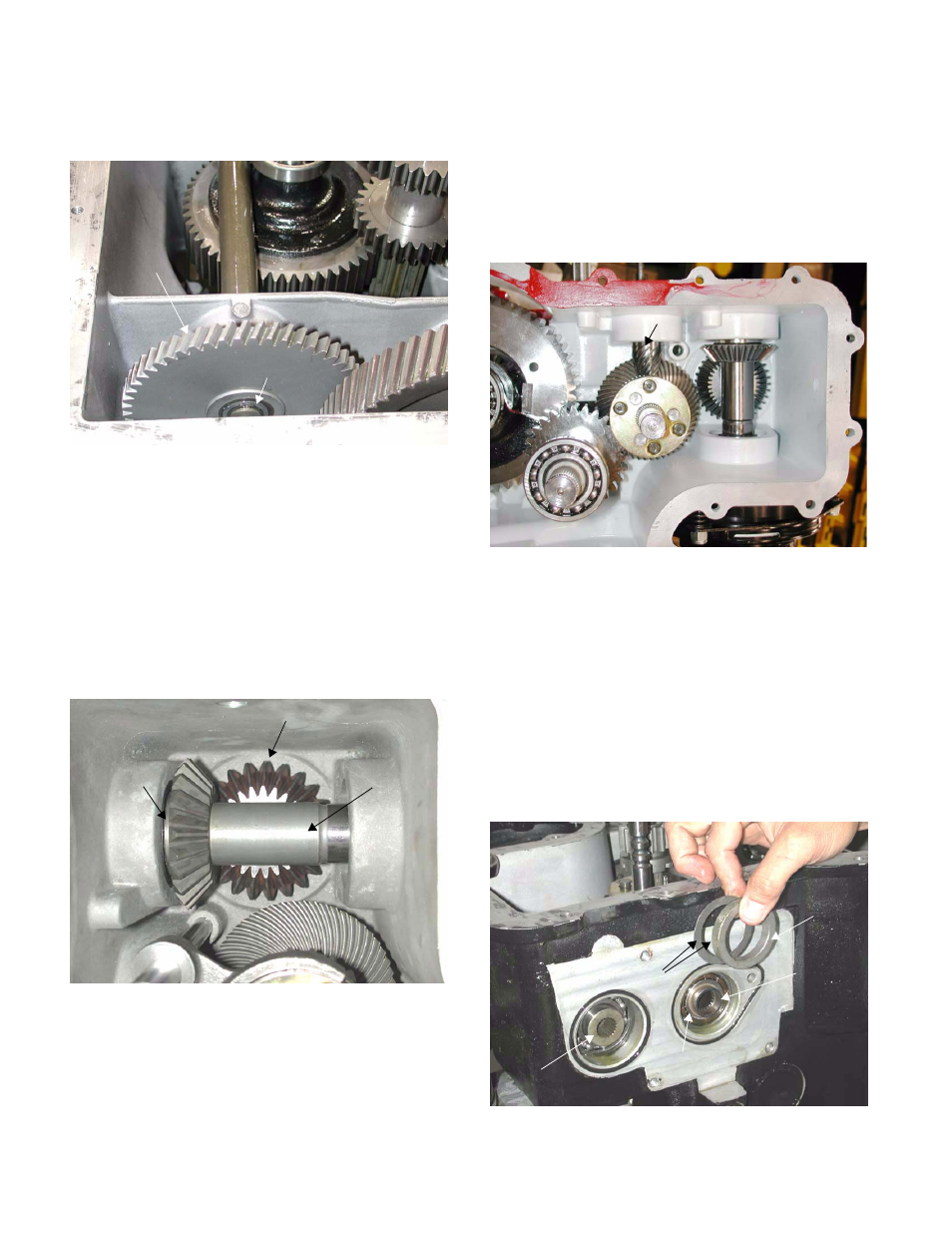

5.26. The front 2000 PTO shaft drive gear can be

removed as the shaft slides forward.

5.27. The PTO system is driven by a shaft that passes

through the hydrostat, providing power to the

variable displacement pump in the hydro and the

charge pump in the hydro.

5.28. The direct-driven output shaft from the hydro

(passing through the variable displacement

pump) drives the auxiliary pump (mounted on

the transmission housing) through a set of bevel

gears. The same shaft drives the electric PTO

clutch.

5.29. The lower output shaft from the hydro. is driven

by the fixed displacement pump in the hydro.

The lower shaft responds to the output of the

variable displacement pump with changes in

speed and direction. The variable displacement

pump responds to control inputs from the opera-

tor.

5.30. The input spiral pinion gear that is driven by the

lower output shaft of the hydro is suspended on

its own ball bearing. A stem on the spiral pinion

gear passes through the bearing, and is secured

there by a retaining ring.

5.31. The ball bearing is held in the base of its bore by

the hydrostat. A spacer and a flat washer

between the body of the hydro. and the bearing

set the end play of the gear.

NOTE: Because backlash between the input spi-

ral pinion gear and the spiral bevel gear is a

function of each gears’ end play, different thick-

nesses of flat washer are used to adjust the end

play (backlash) of the spiral pinion gear. Flat

washers are available in thicknesses of .005”,

.015”, and .030”.

Figure 5.26

Retaining ring

2000 PTO

pinion gear (front)

Figure 5.28

PTO

Input

Shaft

Bevel gear

driving auxiliary

pump

Bevel gear

PTO input shaft

of hydro

driving off

fixed

displacement

motorshaft

Figure 5.30

Input spiral pinion gear

off of variable displacement

pump shaft

Figure 5.31

Flat

washers

Spacer

PTO

input

shaft

shoulder

of

spiral

bevel

gear

snap ring