Checkline CAP-TT01 User Manual

Page 19

Series TT01 Digital Cap Torque Testers

User’s Guide

18

13 CALIBRATION

13.1 Initial Physical Setup

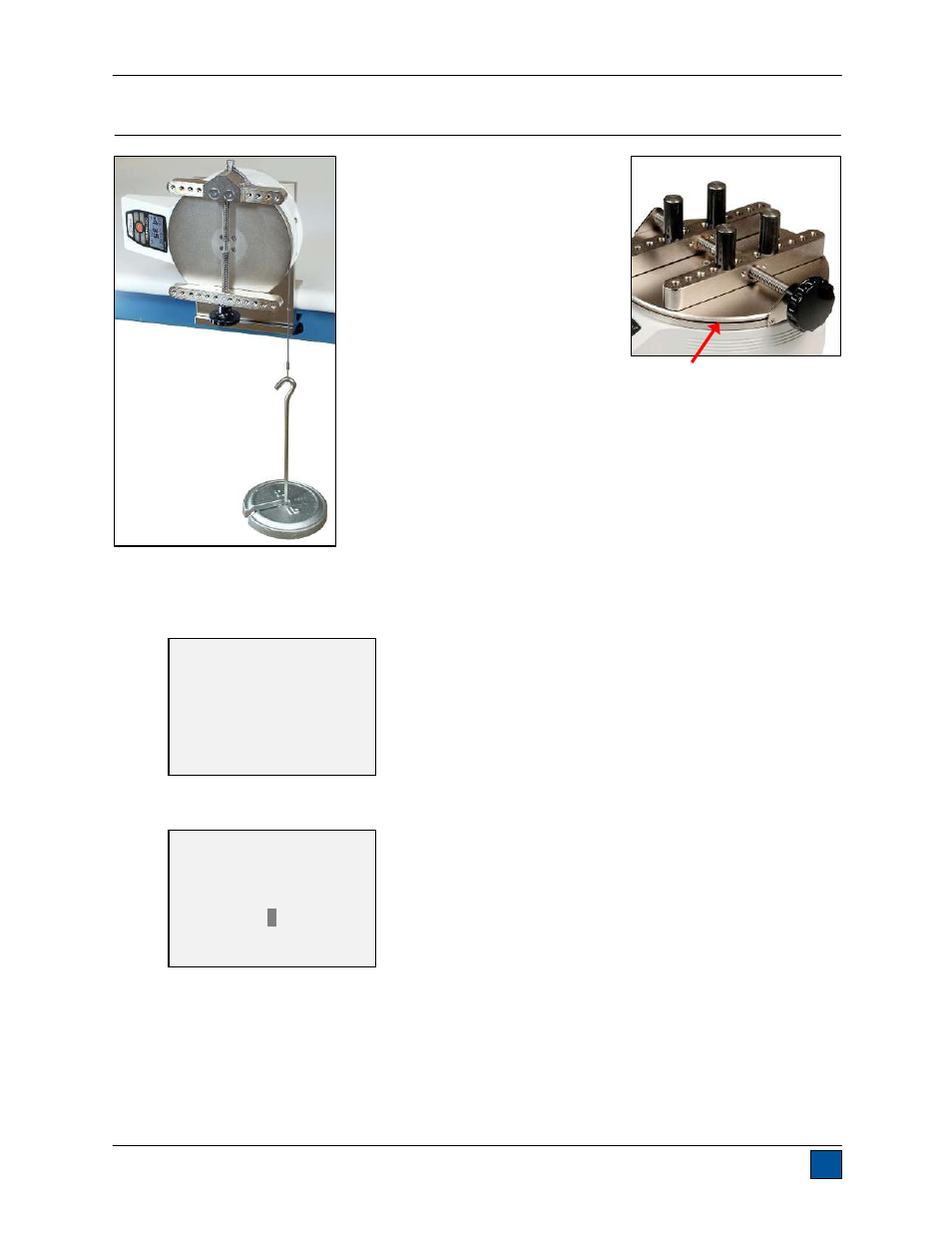

The TT01 should be mounted to a

fixture rugged enough to withstand a

load equal to the full capacity of the

tester. Suitable calibration equipment

is required, and caution should be

taken while handling such equipment.

The AC1036 calibration kit is available

from Mark-10, shown at left.

Note the circular groove in the top

plate, shown at right, which

accommodates a cable for suspension of deadweights. The AC1036

calibration kit includes a cable with a diameter of 0.063 in [1.6 mm] for

insertion into this groove. The cable radius plus the circular groove

radius is equal to 3.333 in [84.66 mm]. Commonly available Imperial

deadweights may, therefore, be employed to achieve full scale

Imperial (i.e. lbFin) loads. For example, a 15 lb load multiplied by 3.333

in. will produce 50 lbFin of torque.

Metric unit calibrations are also possible through the configurable

calibration procedure described below:

13.2 Calibration Procedure

1. Select

Calibration from the menu. The display appears as follows:

2. Press

DIRECTION to invert the display, if desired. ENTER to continue. The display appears as

follows:

The tester can be calibrated at up to 10 points in each direction. Enter the number of calibration

points for each direction (clockwise and counter-clockwise). At least one point must be selected

for each direction.

Note: To achieve the accuracy specification of ±0.3%, it is recommended to calibrate the tester at

5 or more even increments in both directions. For example, an MTT01-50 should be calibrated at

10, 20, 30, 40, and 50 lbFin loads in each direction.

CALIBRATION

To invert the

display, press the

DIRECTION button,

then press ENTER.

CALIBRATION

Enter # cal points

(1 to 10)

Clockwise:

5

Counter-clockwise:

5