Installation and operating instructions – Pilz PSEN me1.21S / 1AR User Manual

Page 5

Installation and Operating Instructions

Date of issue: 22.02.2006 / Page 11 of 12

Document : 0800000458 / Version: 01 / 2196-06

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: [email protected], www.pilz.com

Template : 0850174292 Orig. 2

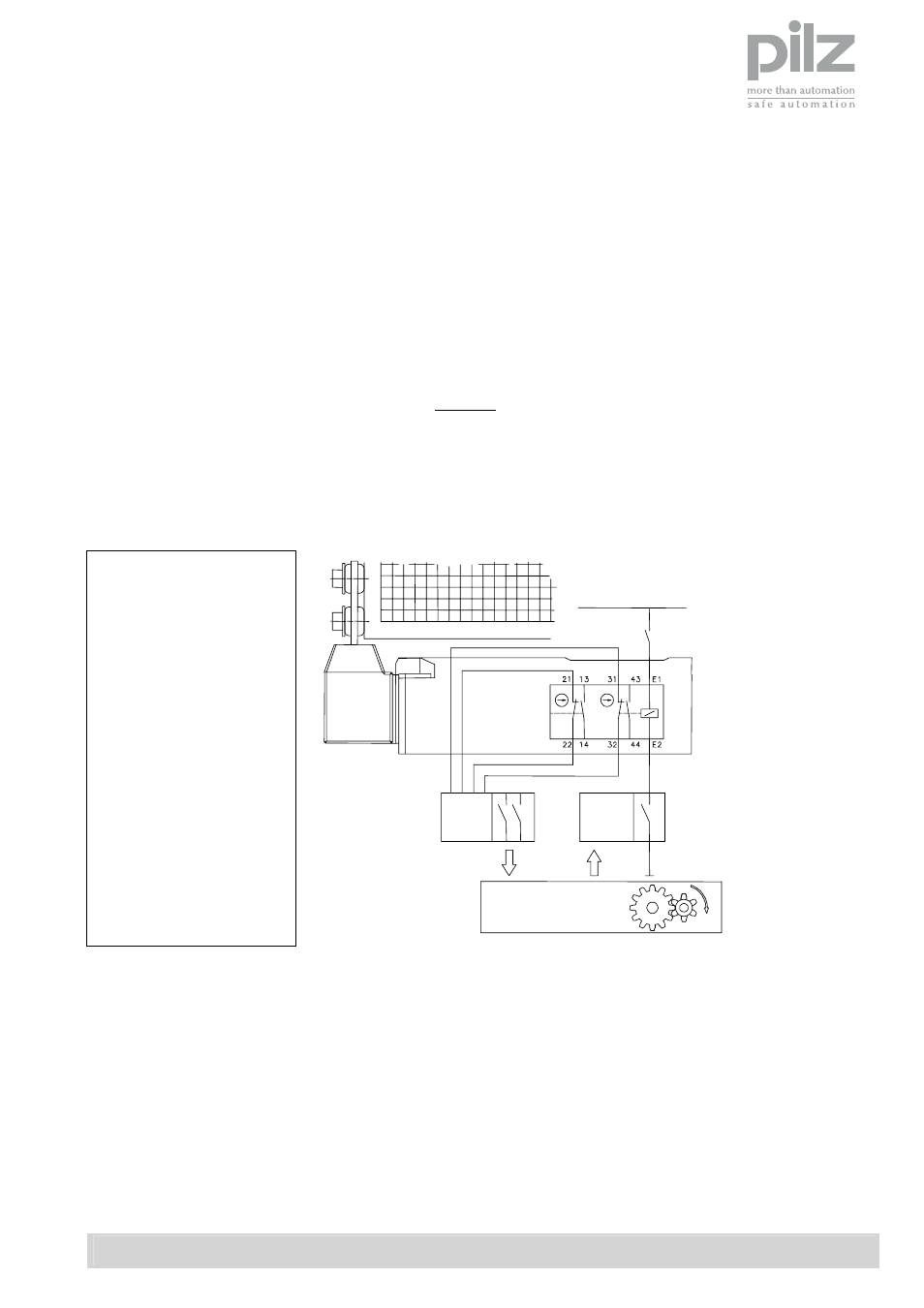

System description / Suggested application

When the machine guard is closed, the actuator is engaged and locked in the safety switch. In this state the safety outputs in

the safety control module are closed and the contact in the control module (for the solenoid) is open - the machine can now

operate.

In order to carry out maintenance work behind the safety guard the operator has to switch off the machine. This will cause

opening of the outputs of the control module and shutoff of the machines power line. As the dangerous movement of the

machine may not stop immediately, the safety switch lock should only release the actuator after the machine has come to a

complete stop. A suitable control module, e.g. a lost-motion monitor or a delay module (safety timer) can be used for that

purpose.

The safety contacts (force disconnected N.C.) inhibit the machine from restarting whilst the machine guard is open. The

additional N.O. contacts can be used as signaling contacts, they do not have a safety function and are normally used for

indication only. These functions do not conduce safety, just availability of machinery. When used in conjunction with suitable

control modules the NO contacts may be used only for additional verification of the safety circuit.

The set of contacts monitoring the safety guard is form-fit driven by the actuator, so that the position of the safety guard is

directly monitored. The set of contacts monitoring the locking device has a positive drive connection to the lock. Thus ensures

that any failure of the locking device will be immediately detected by the safety control system. An integrated mechanical

mechanism ensures that the lock cannot be engaged whilst the actuator is removed from the safety switch.

The safety switch PSEN me1 can be applied in combination with other safety switching devices and safety control modules in

systems up to control category 4 acc. to DIN EN 954-1 when the applicable standards are maintained.

Maintenance / Inspection

The switching device is

maintenance-free. For trouble-free

operation and a long service life

the device should be inspected

regularly. Ensure that:

- all components are secure and tight

- switching functions operate properly

- all sealing gaskets are in proper

condition

- the components show no signs

of tear and wear.

If defects are the detected the

complete switching device and the

actuator have to be replaced.

Liability disclaimer

By breach of the given instructions

(concerning the intended use, the

safety instructions, the installation

and connection through qualified

personnel and the testing of the

safety function) any liability

expires.

- actuator inserted and locked

- solenoid un-energised

Control voltage

Control contact

Actuator

contacts

(guard position)

analysing

module

control

module

Hazardous machinery

Solenoid contacts

(guard locking)

Contact assignment

illustrated for standard type :

PSEN me1S/1AS

570000