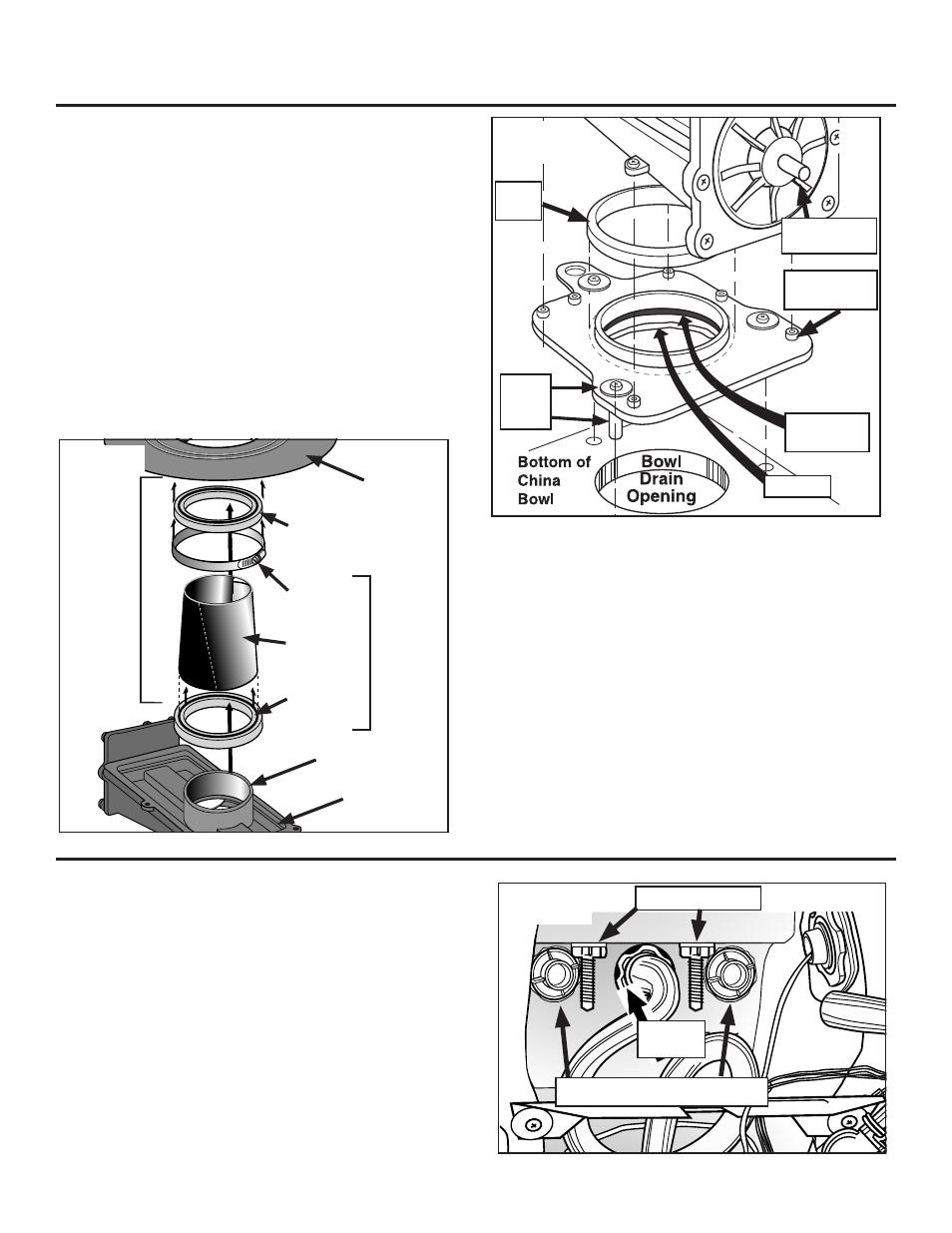

Fig. i, Fig. h, Fig. g – Thetford 19621 - Seal Replacement Package User Manual

Page 3: High profile only, Replacing flush nozzle seals

Replacing Flush Nozzle Seals

This does not require removing the Mechanism.

To Remove Old Parts

1. Disconnect 2 upper Tubes from outside Nozzle Connectors (Fig.

I).

2. Cut Tie Strap securing Solenoid Valve to Metal Bracket (Fig. J).

3. Being careful not to bend Metal Bracket, slide Solenoid Valve out

of slot in Bracket. Swing entire Valve/Hose Assembly down and to

right out of the way. Support it to avoid putting stress on the Wire

Harness.

4. Pop up Seat/Lid Bolt Covers (hinged from rear).

Fig. I

Hinge Post Bolts

Outside Nozzle Connectors

Locking

Nut

Part #19621

Seal Replacement Package

Page 3

Mounting

Flange

Fig. H

Shown

separate for

clarity – these

items nor-

mally remain

assembled

HIGH

PROFILE

ONLY

Extension

Tube

Mounting

Flange Seal

Extension

Tube Seal

Clamp

Flat Foam

Seal

Mechanism

Lead Screw

Blade

Seal

Mechanism

Plate

Sealant

Well-nut

ass’y

Fig. G

Mechanism

Tube Lip

Mechanism

some low-profile units, it may be a tight squeeze. Align mechanism over Mecha-

nism Plate, press down and secure with four screws (MS, Fig. D).

6. Turn toilet over to check centering. Loosen well-nuts to re-center if needed.

Do the permanent tightening down of the well-nut screws at this

time by hand. Tighten in a diagonal pattern to get an even seal. Be

careful not to overtighten and cause deflection of the plate at the

edges. Wipe off excess sealant when done.

7. Cut approximately 1” off Overflow Tube. Forming a full loop, reattach to

Mechanism. Tuck in and away from lead screw.

8. If you removed the Controller Assembly and/or the Switch Box, re-install

now, using the adhesive foam pads provided. If you removed Metal

Bracket, reinstall.

9.

High Profile: To install Extension Tube (Refer to Fig. H):

a. Lubricate sealing surface of Extension Tube Seal with silicone

grease.

b. Install Extension Tube Seal on Extension Tube.

c. Install Extension Tube and seal assembly on Mechanism. Make sure

that seal is seated at least 1/2 inch below Mechanism tube lip.

d. Ensure Hose Clamp on Mounting Flange Seal is tight.

e. Lubricate Mounting Flange Seal sealing surface with Silicone

Grease.

f. Install Mounting Flange and Seal assembly on Extension Tube. Make

sure there is at least a 1/2” overlap between the Extension Tube

and Mounting Flange Seal.

Low Profile: Replace the Mounting Flange Seal onto the lip of the

Mounting Flange. Install Mounting Flange to Mechanism. (No extension

tube is used.)

10. Replace 2 Mounting Bushings with flat surface out.