Vessel attachments, Piping, Example i – Rice Lake Weigh Modules/Mount Assemblies User Manual

Page 55

3-3

VESSEL ATTACHMENTS

Piping

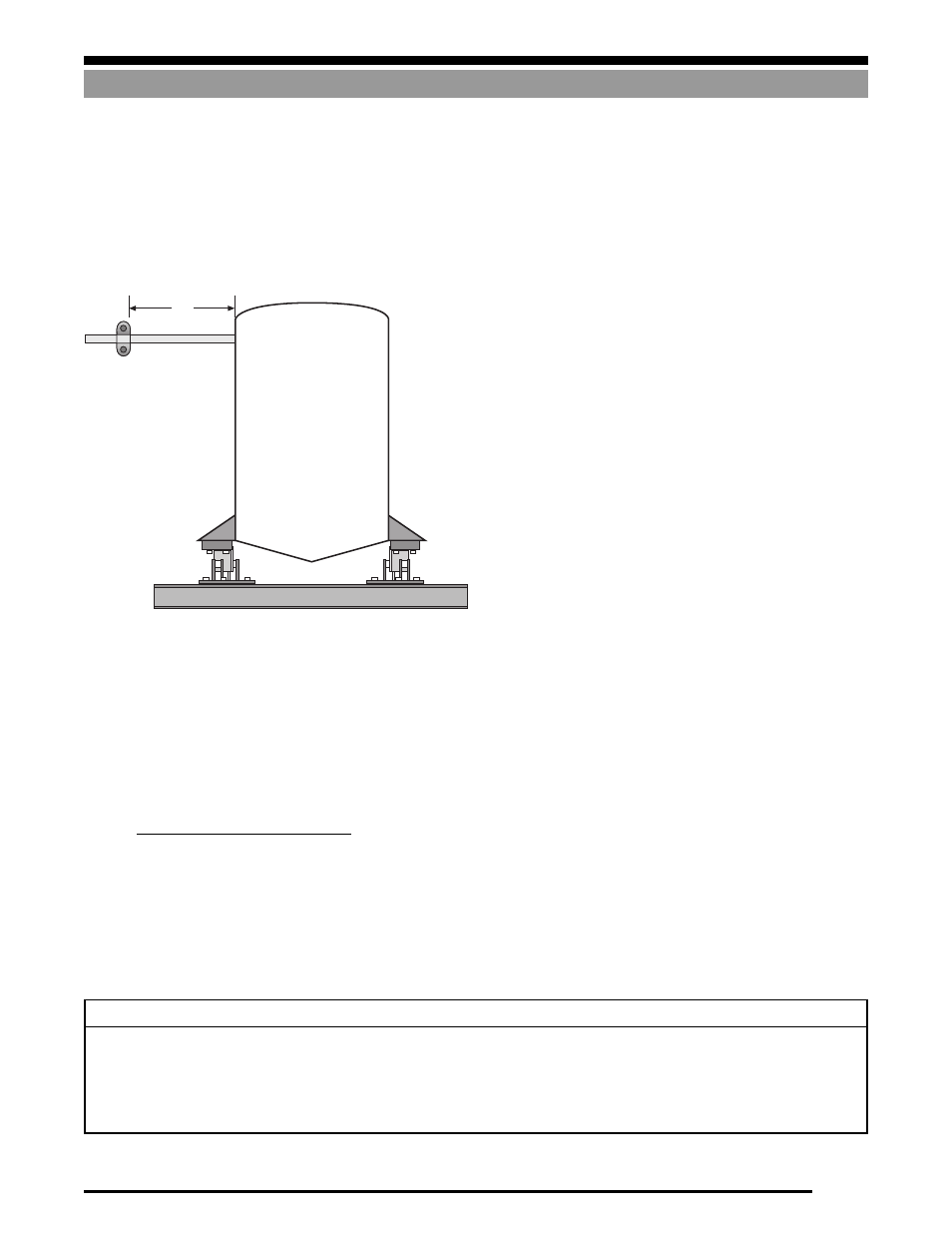

Figure 3-3

Example 2 shows the effect of doubling the length of pipe between

the vessel and first support point. The 87% reduction shows that F

1

can be greatly decreased by increasing the distance to the first

support point.

Example 3 shows the effect of cutting the structural deflection in

half from .250" to .125" (the load cell deflection of .008" remains the

same). It is obvious from the 48% reduction in Table 1 that F

1

can

be moderately decreased by reducing the vessel’s deflection.

Example 4 shows the effect of using a lighter-wall schedule 10S

pipe instead of schedule 40.

Example 5 shows the effect of reducing the size of the pipe from 4"

schedule 40, to 2" schedule 40. From the large 93% reduction, it is

clear why you should always use the smallest diameter pipe suitable

for the application.

These and other Do’s and Don’ts are summarized in the Piping

Guidelines section. Note that while the emphasis here is on at-

tached piping, these recommendations apply equally to attached

electrical conduit and cables.

If several pipes are attached to a vessel, the vertical force exerted on

the vessel can be calculated for each individually, as described

above, then added together to get the total force F acting vertically

on the vessel. That is:

F = F

1

+ F

2

+ F

3

…

where F

1

is the force exerted by pipe 1, F

2

the force exerted by pipe

2, etc.

Accepted practice in the scale industry for ensuring that piping does

not adversely affect the required accuracy is to ensure that the

following relationship is satisfied:

F

≤

.1 x system accuracy (in%) x live load (lb)

* For 4" Schedule 10S, D=4.50, d=4.26

†

For 2" Schedule 40, D=2.38, d=2.16

From the above information:

∆

h = .008" + .250" = .258"

E(steel) = 29,000,000

For schedule 40 pipe, D = 4.50, d = 4.03

l = 36"

hence:

F

1

=

=

13,840 lb.

The first line of Table 1 (Example 1) summarizes the above result. The

other lines (Examples 2–5) represent the result when one parameter is

changed. The last column on the right expresses the % change in F

1

relative to Example 1 (13,840 lb).

Table 1

Example

Pipe

Pipe Length(l) Deflection(

∆

h

) Upward Force(

F

1

) Percentage Reduction in (

F

1

)

1

4" schedule 40

36"

.258

13,840

---

2

4" schedule 40

72"

.258

1,730

87%

3

4" schedule 40

36"

.133

7,130

48%

4

4" schedule 10S*

36"

.258

7,630

45%

5

2" schedule 40

†

36"

.258

976

93%

Example I

A steel tank is supported on load cells and a steel structure with

deflections of .008" and .250" respectively under load. A 4" schedule

40 pipe is attached horizontally with 36" free span between the

vessel and the first support point. What force F

1

is exerted upward

on the vessel?

36"

.59(4.50

4

– 4.03

4

) x .258 x 29,000,000

36

3