Double-end beam load cell modules, Weigh modules, Double-end beam orientation – Rice Lake Weigh Modules/Mount Assemblies User Manual

Page 39: General mounting principles, Introduction

WEIGH MODULES

2-10

Double-Ended Beams

Double-End Beam Orientation

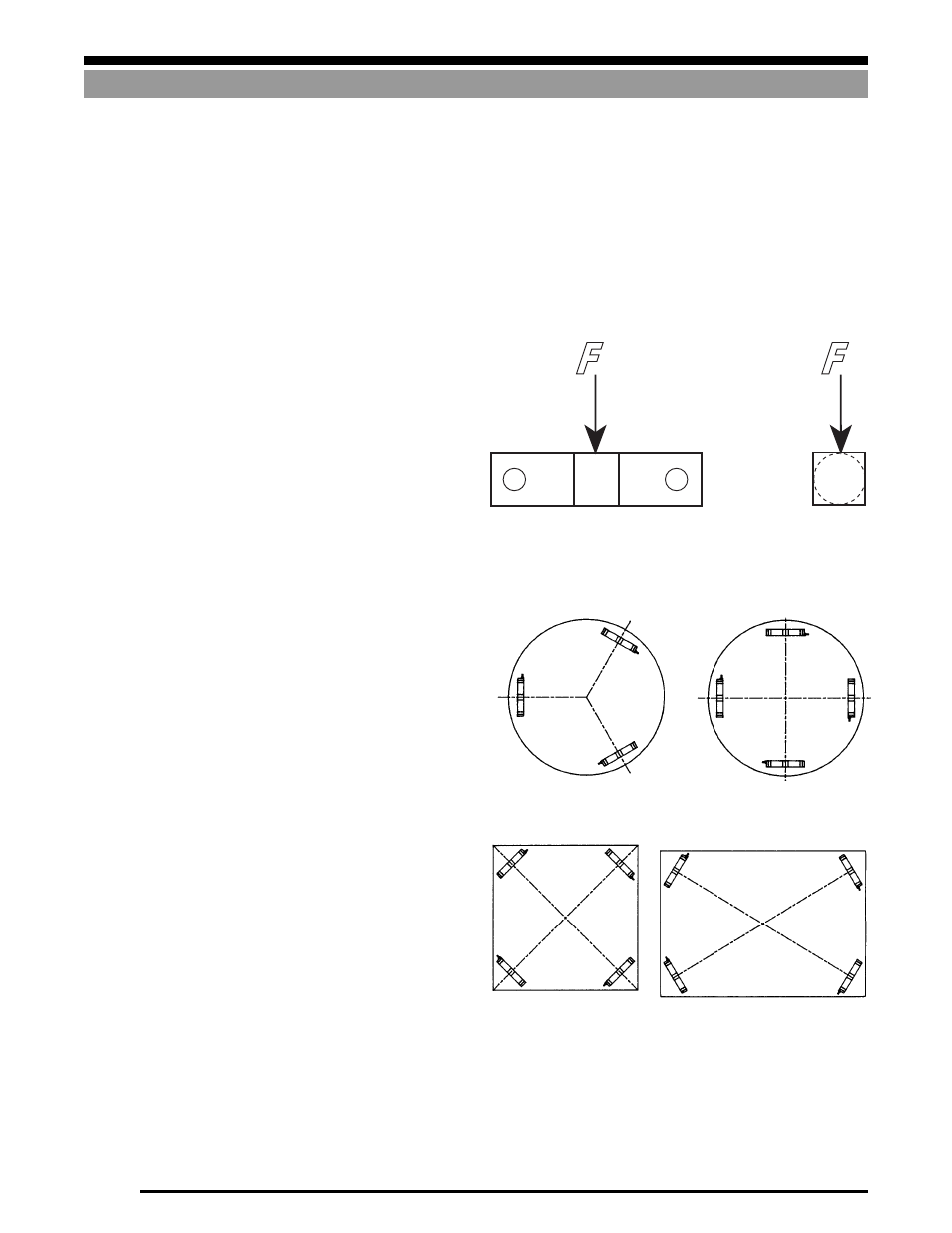

In Figure 2-19, we illustrate some recommended mounting meth-

ods for double-ended shear beams used in the RL1600 and EZ

Mount 1.

The mounts for these cells allow the least restricted vessel move-

ment in a direction perpendicular to the longitudinal axis through

the cell.

The best mounting position for several vessel shapes is shown at

right, where a line from the center of the vessel is at right angles

to the longitudinal axis through the load cell. These recommen-

dations are particularly important when significant thermal ex-

pansion/contraction is expected.

The TSA module should be oriented with the load cell’s longitudi-

nal axis in line with the expected movement. On a truck scale, that

will normally be in the direction of truck travel. See Figure 2-25.

General Mounting Principles

•

The load cell should be horizontal in both directions.

•

The load should be applied vertically through the cell’s center.

•

The load should be introduced without producing a twisting

effect around the center.

•

The load must not move along the cell.

Figure 2-18

Double-End Beam Load Cell Modules

Introduction

Double-end shear beams are medium- and high-capacity workhorses that are rugged, stable, and able to handle side loads well. The

modules come in two varieties—end-supported cells loaded in the center, and center-supported cells loaded at the ends. The end-loaded

cell is used in the Translink hanging-link truck scale module described later in this section. The more common center-loaded version

described below is used in the RL1600, EZ Mount 1, and TSA mounting systems.

Figure 2-18 shows some important guidelines for applying load to a center-loaded, double-ended shear beam and for orienting a module

using this type of load cell.

Figure 2-19