Stay rod expansion/contraction, Vessel expansion/contraction, System design – Rice Lake Weigh Modules/Mount Assemblies User Manual

Page 14: Thermal expansion, 48" 1" dia

SYSTEM DESIGN

1-12

Thermal Expansion

Calculating Thermal Expansion of Vessels & Stay Rods

Stay Rod Expansion/Contraction

Stay rods attached to vessels subjected to thermal changes can

introduce significant forces which affect system accuracy. The

method of attachment and the length of the stay rods directly affect

these forces.

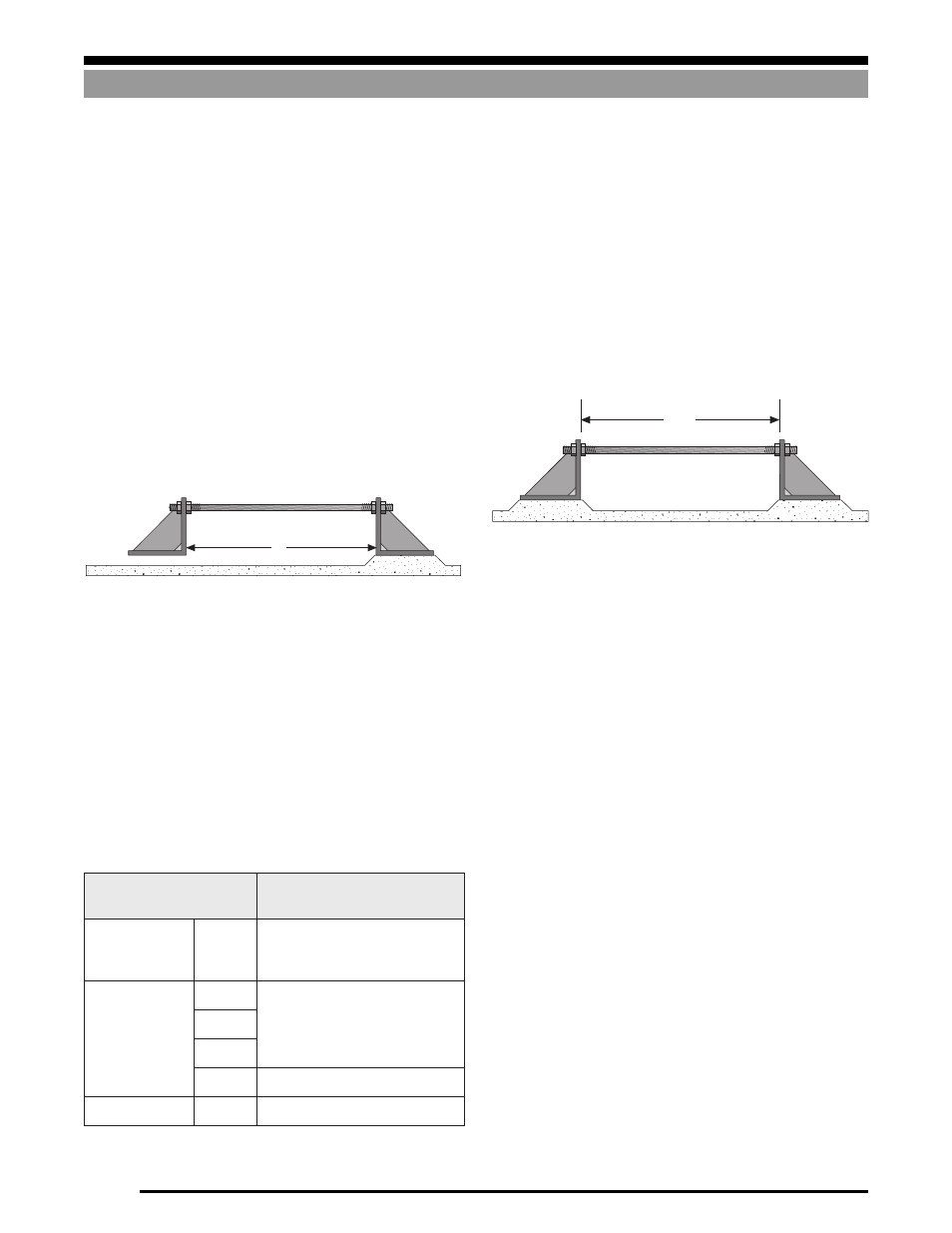

Figure 1-19 illustrates a stay rod rigidly attached to a bracket on

each end—one bracket is rigidly mounted, the other is unattached,

thus allowing the rod to expand and contract freely. As the tem-

perature rises or drops, the length of the rod will increase or

decrease respectively. The change in length (

∆

L) is proportional to

the original length (L), the change in temperature (

∆

T), and the

coefficient of linear expansion (a) which is a characteristic of the

rod material.

∆

L can be calculated from the following equation:

∆

L = a x

L x

∆

T

Figure 1-19

Table 1-1 below lists the coefficient of thermal expansion (

α

) for

various materials used to construct vessels and stay rods.

Example:

If the rod in Figure 1-19 is made from 1018 steel, then a = 6.5 x 10

-

6

from Table 1-1. If the rod is 48" long and the temperature

increases by 60

°

F, the length of the rod will increase by:

∆

L = a x L x

∆

T

∆

L = 6.5 x 10

-6

x 48" x 60

∆

L = .019

This shows that a 48" steel rod will increase by .019" as a result of

a 60

°

F temperature rise. This may seem insignificant, until you

consider the forces which can result if the stay rod is confined

rigidly at each end, as in Figure 1-20.

In Figure 1-20, a 1" steel rod 48" long is attached to a bracket on

each end, and both brackets are rigidly attached. If the rod is

initially adjusted so that there is no strain, a subsequent 60

°

F rise

in temperature will cause the rod to exert a force of 9,000 lb on each

bracket. Hence, vessel restraint systems must be designed and

installed properly so that they don’t move and/or apply large lateral

forces to the weigh vessel.

Vessel Expansion/Contraction

Temperature fluctuations will cause weigh vessels to grow and

contract. Figure 1-21 on the following page best illustrates this.

Shown is a top view of a rectangular vessel. The solid line repre-

sents its size at 70

°

F and the inner and outer broken lines represent

its size at 40

°

F and 100

°

F respectively. The amount that the sides

will increase/decrease in length can be found using the expansion

formula discussed previously.

Therefore:

∆

L = X x L x

∆

T

L

Figure 1-20

48"

1" Dia

l

a

i

r

e

t

a

M

n

o

i

s

n

a

p

x

E

r

a

e

n

i

L

f

o

t

n

e

i

c

if

f

e

o

C

r

e

p

s

e

h

c

n

i(

°

)

F

l

e

e

t

S

w

o

L

n

o

b

r

a

c

)

8

1

0

1

(

0

1

x

5

.

6

6

-

l

e

e

t

s

s

s

e

l

n

i

a

t

S

2

0

3

0

1

x

6

.

9

6

-

3

0

3

4

0

3

6

1

3

0

1

x

9

.

8

6

-

m

u

n

i

m

u

l

A

1

6

0

6

0

1

x

0

.

3

1

6

-

Table 1-1