Common hopper scale arrangements, Common hopper scale arrangements -3, System design – Rice Lake Weigh Modules/Mount Assemblies User Manual

Page 5

1-3

SYSTEM DESIGN

Bulk Material Weighing Systems

Common Hopper Scale Arrangements

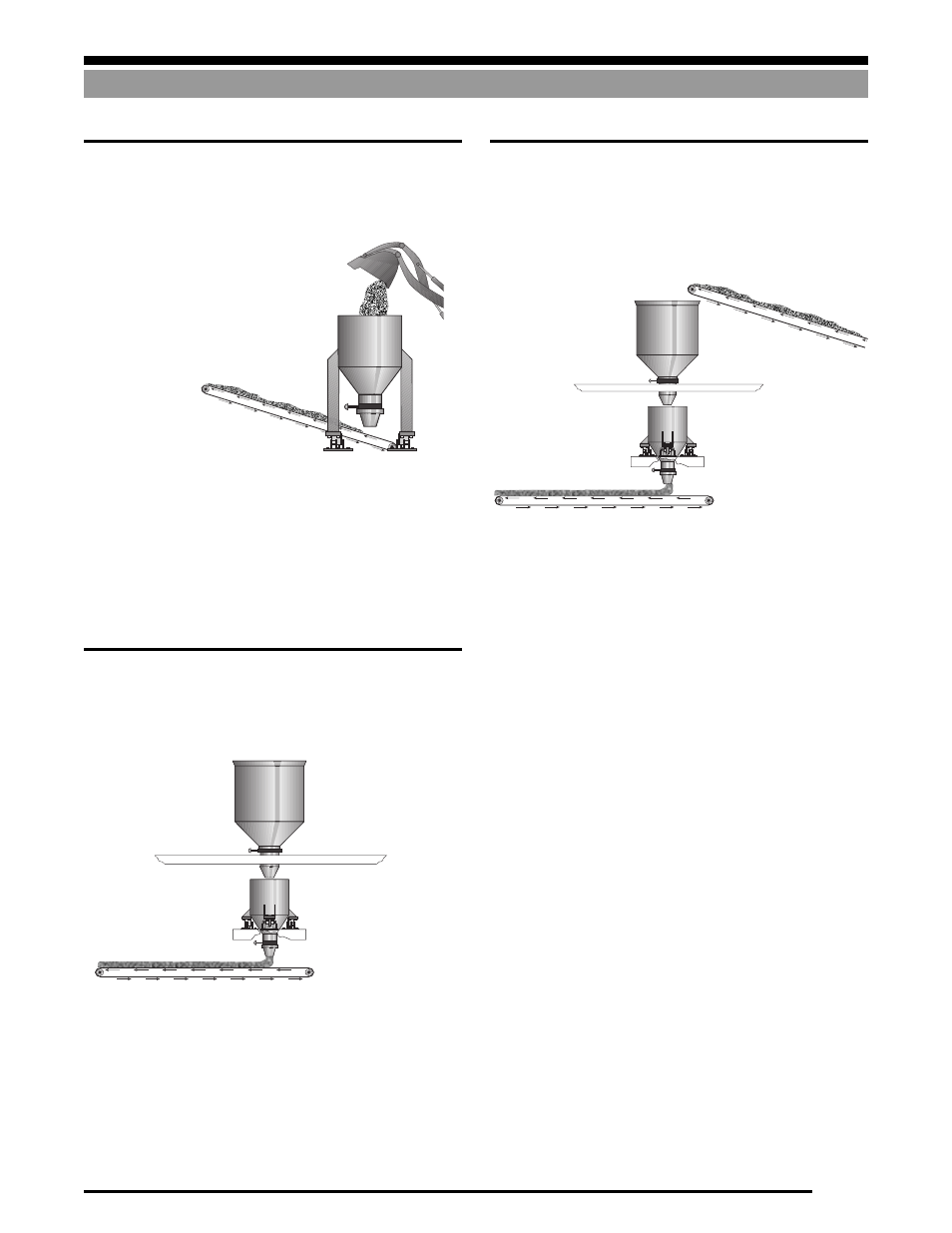

C. A conveyor-fed system can be improved by adding an upper

surge hopper as shown in Figure 1-7. The surge hopper allows

the conveyor to be run continuously and isolates the weigh

hopper from the sometimes erratic flow of material from the

conveyor.

Advantages of this system are:

•

Weigh hopper isolated from the feed conveyor.

•

The input conveyor can run continuously.

•

Surge hopper serves as a buffer to smooth out demand.

•

2-speed fill is possible.

•

Faster fill and higher throughput possible.

Disadvantages of this system are:

•

Higher overall height.

•

Higher cost.

•

More complex controls and mechanical arrangement.

A.

One of the simplest hopper weighing systems is illustrated

below in Figure 1-5. The weigh hopper may be filled using a

feed conveyor, front-end loader, auger, etc., and the material

may be removed from the hopper using a discharge conveyor.

Advantages of this system are:

•

Low cost compared to other systems.

•

Low overall height.

Disadvantages of this system are:

•

Slow fill and discharge (low throughput).

•

Difficult to achieve an accurate prescribed weight because

of inconsistency in input material flow.

B. Figure 1-6 below illustrates a weigh hopper positioned

directly under the storage silo.

Advantages of this system are:

•

The weigh hopper is gravity-fed, simplifying the feed process

and providing a more uniform flow.

•

Faster fill cycle and hence greater throughput.

•

2-speed fill may be used for greater target accuracy.

Disadvantages of this system are:

•

Higher overall height.

•

Material must be conveyed higher to storage silo.

Figure 1-5

Figure 1-6

Figure 1-7