0 maintenance, 1 maintenance schedule, Maintenance – Rice Lake Mobile Group Animal Scale - MAS-M - Operators Manual User Manual

Page 34

30 MAS-M Operator’s Manual

5.0 Maintenance

5.1 Maintenance Schedule

Before Each Use

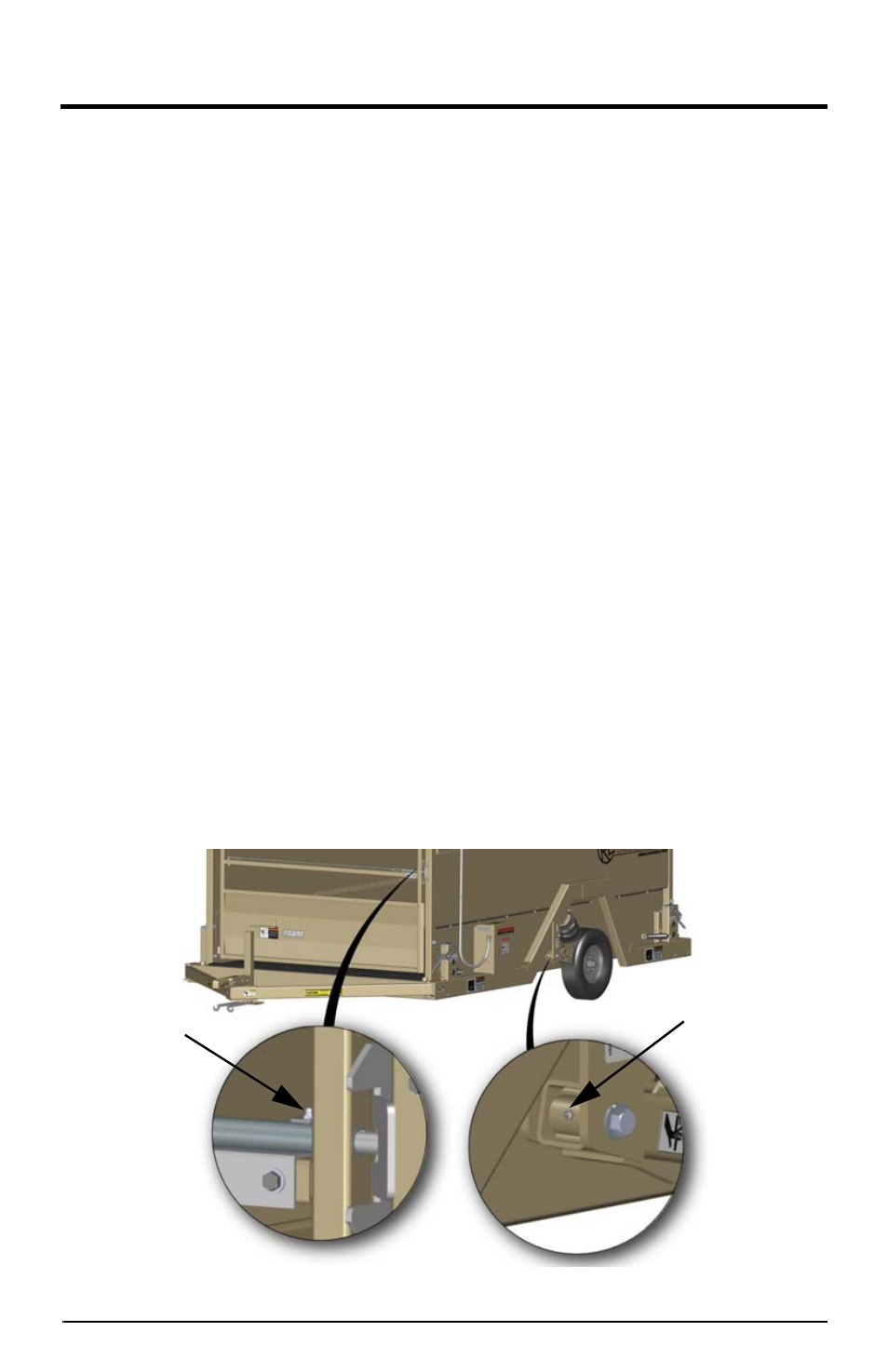

1. Grease axle pivot locations, using the provided grease zerks (see Figure 5-1),

using a “Black Moly” type grease.

First Week

1. Check torque on all wheel nuts (see Section 5.3.4 on page 33).

Weekly

1. Check entire scale for buildup of debris. Remove any debris found on, under or

around the scale. Rubber T-belting at both ends of the scale are removable to

make clean out easier. To remove T-belting, unhook the stretch cord that hooks

into the corner tube of the cage.

2. Check for dirt and debris in the load cell stands and clean accordingly.

3. Check all external cables and conduit for damage.

First Month (in addition to weekly maintenance)

1. Check torque on all wheel nuts (see Section 5.3.4 on page 33).

2. Adjust scale brakes.

Monthly (in addition to weekly maintenance)

1. Charge scale battery if necessary.

2. Tire Pressure. 45 psi./40psi. - Single /Tandem Axle

3. Grease gate latch zerks (see Figure 5-1) using a “Black Moly” type grease.

Yearly (in addition to weekly and monthly maintenance)

1. Check and grease wheel bearings (see Section 5.3.5 on page 33).

2. Disassemble each load cell location and grease all pins and eye bolts (see

3. Adjust scale brakes (see Section 5.3.3 on page 32).

Figure 5-1. Grease Zerk Locations

Grease zerk

on gate

latches

Grease zerk

at axle pivot