1 wheel assembly and torque specification, Wheel assembly and torque specification – Rice Lake Mobile Group Animal Scale - MAS-M - Operators Manual User Manual

Page 14

10 MAS-M Operator’s Manual

2.2.1

Wheel Assembly and Torque Specification

It is extremely important to apply and maintain proper wheel mounting torque on the

scale axle. Torque is a measure of the amount of tightening applied to a fastener (nut

or bolt) and is expressed as length times force. For example, a force of 90 pounds

applied at the end of a wrench one-foot long will yield 90 ft-lbs of torque. Torque

wrenches are the best method to assure the proper amount of torque is being applied.

Wheel bolts/nuts must be tightened and maintained at the proper torque

levels to prevent loose wheels, broken studs and possible dangerous

separation of wheels from the axle. Be sure to use only the fasteners

matched to the cone angle of the wheel (usually 60° or 90°).

The proper procedure for attaching the wheels is as follows:

1. Start all bolts/nuts by hand to prevent cross threading.

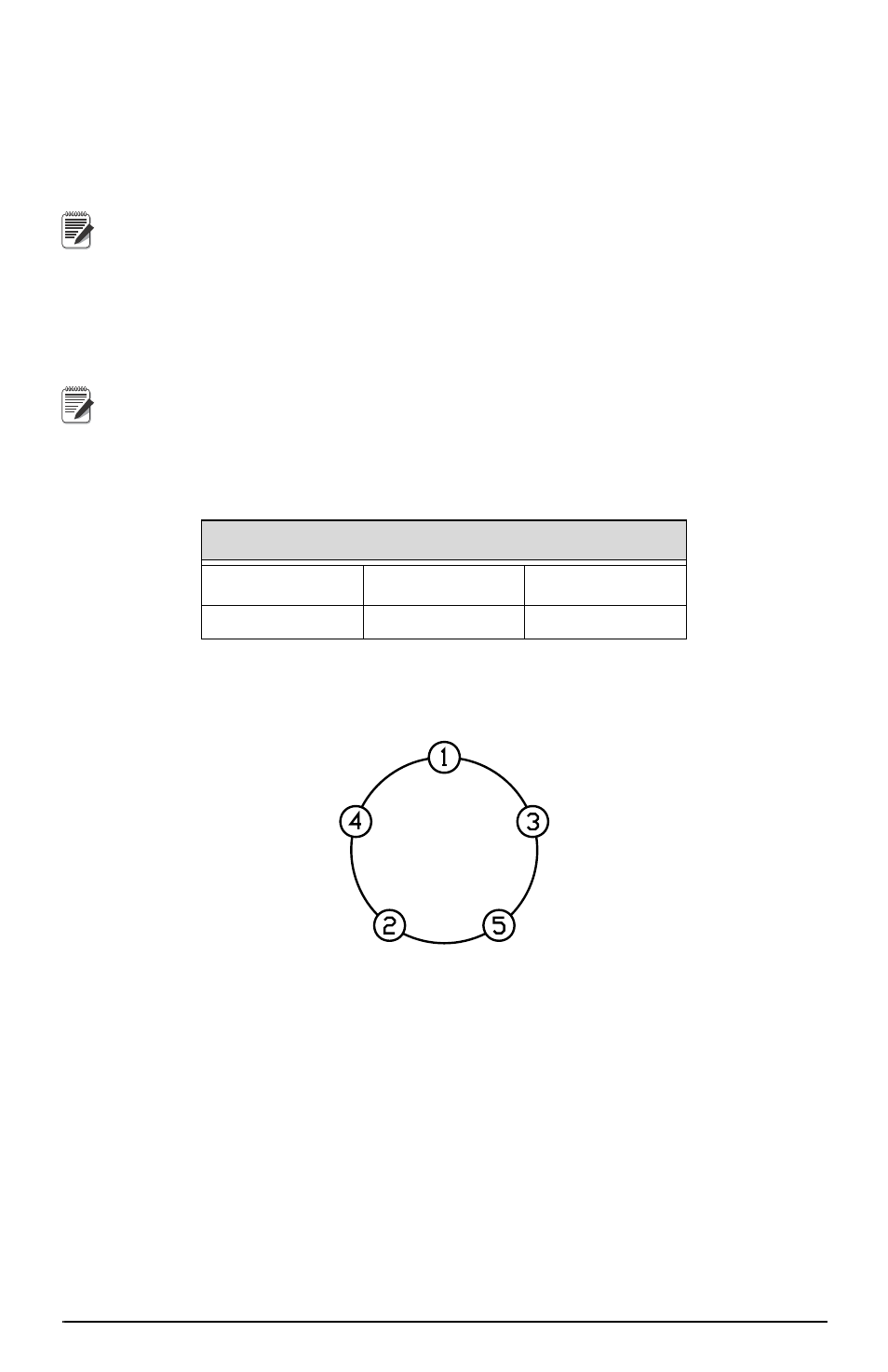

2. Tighten bolts/nuts in the sequence shown in Figure 2-4.

The tightening of the fasteners should be done in stages, following the

recommended sequence, tighten fasteners per torque chart in Table 2-1.

3. Wheel bolts/nuts should be re-torqued after the first 10 miles, 25 miles and

again at 50 miles.

Figure 2-4. Wheel Torque Pattern

4. Once the wheel nuts have been torqued use a white marker to mark the end of

each stud to show they have been torqued.

Wheel Torque Sequence (ft-lbs)

1st Stage

2nd Stage

3rd Stage

20-25

50-60

90-120

Table 2-1. Wheel Torque

Note

Note