Installation instructions – Kontron OmniView User Manual

Page 21

OmniView – User’s Guide (V1.)

20

www.kontron.com

7.

Installation Instructions

The OmniView should be installed and operated only by trained and qualified

personnel.

The unit must be placed such that there is sufficient space for connecting the cables

to the I/O interface connectors.

The voltage feeds must not be overloaded. Adjust the cabling and the external

overload protection to correspond with the rated voltage range indicated on the

type label.

The type label is located on the right side of the system.

The rear access panel must be secured by the supplied screws during operation.

The mount clamps with screws (supplied), allow the easy and fast mounting of the OmniView-

156/185/215. Refer to the appropriate unit outline and mounting drawing for the correct

dimensions of cut-outs and air gap clearances required for mounting the unit into a wall or panel.

The OmniView outline and mounting drawing can be found on our web sit

Dimension for: OmniClient

156

185

215

Cut-Out for Mounting into a Panel

[mm] (W x H)

394 x 245

462 x 283

527 x 325

Requirements for Mounting

Metal mounting panel thickness

for proper mounting

1.5 – 6

1.5 – 6

1.5 – 9

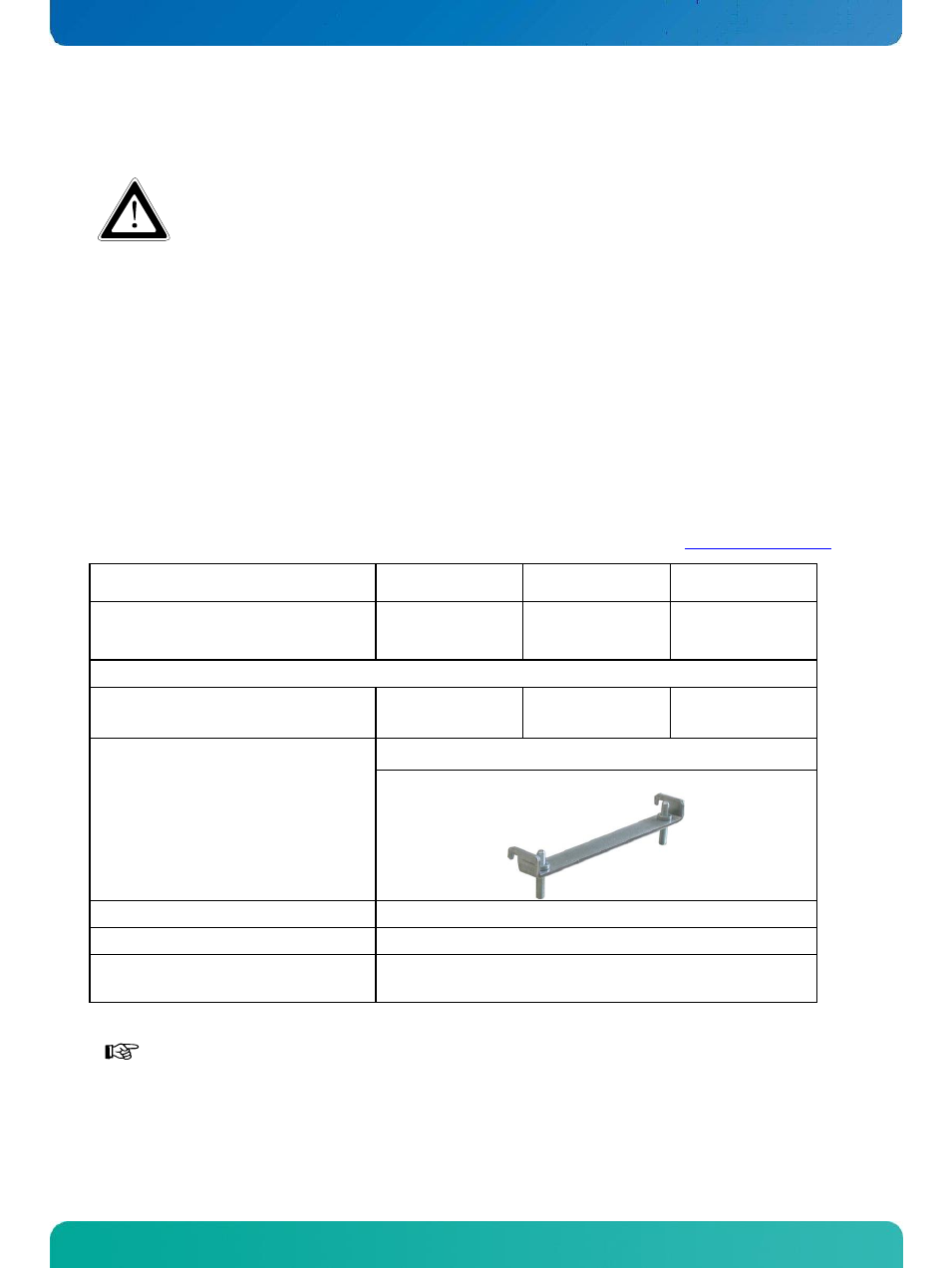

Used clamps with screws for

mounting the OmniClient to

a panel

6x

Required Tool

#2 Phillips Screw Driver

Proper Torque

Tighten the screws with a torque of 0.5 Nm

Mounting Position

Ensure the vertical and horizontal alignment of the

system/display box.

Table 2: Requirements for OmniView mounting into a subframe/panel

In order to ensure IP65 front sealing against dust and water, mount the system on a

non-textured surface. Before you install the OmniView system into a panel or a

subframe for industrial cabinet, verify the perfect condition of the seal at the rear of

the front plate. The seal has to be in place without surface imperfections/defects

and dirt.