Operator installation – Detex AO19-3 User Manual

Page 5

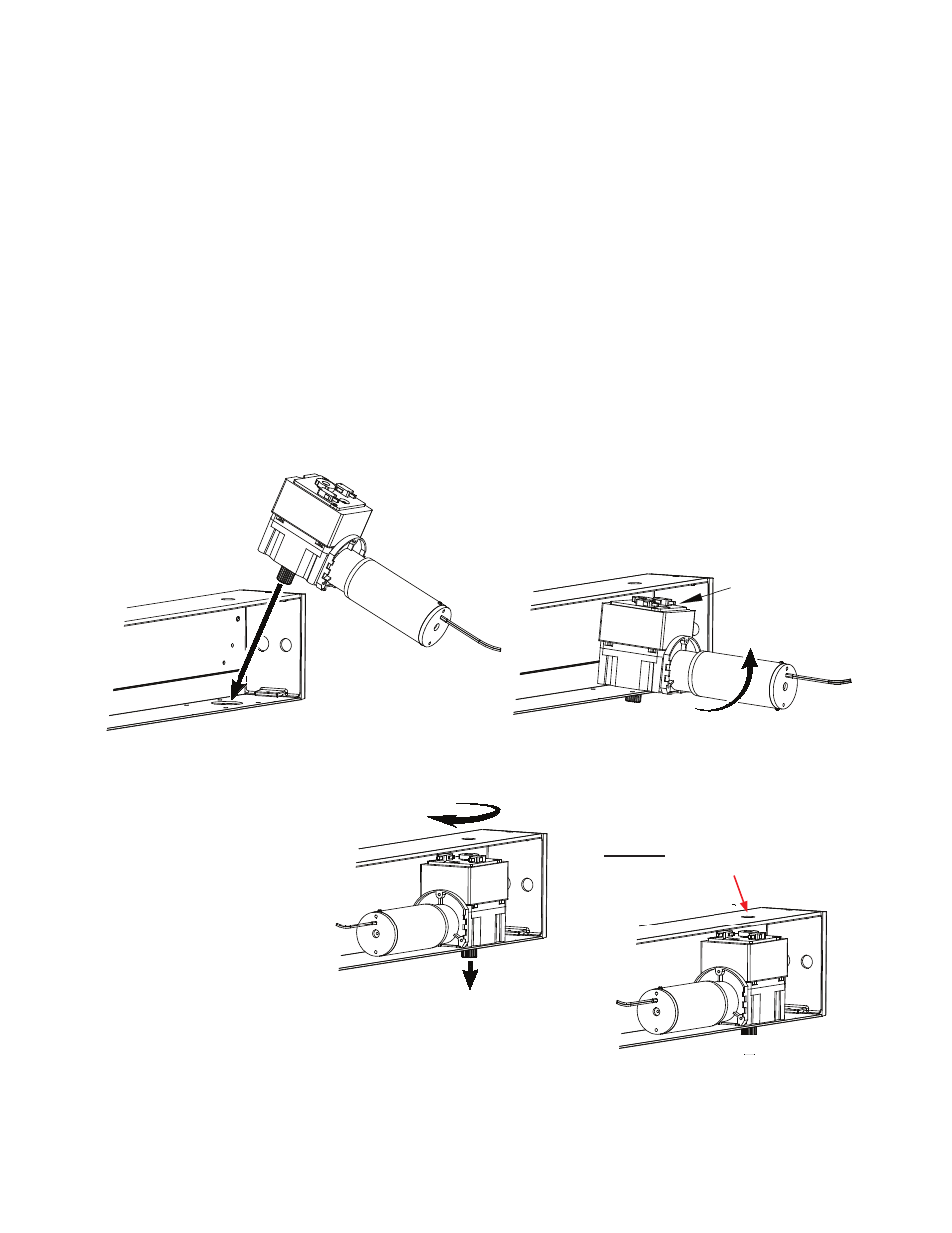

With motor / gearbox

perpendicular to enclosure,

insert splined shaft into

shaft hole

Rotate motor / gearbox

to almost horizontal position

being careful not to let switch

assembly hit enclosure

(Note: For clarity, switch wires not shown in views)

Switch Assembly

Rotate motor / gearbox into

enclosure, letting shoulder of

gearbox drop down into shaft

hole. Align screw holes at bottom

& install all 4 screws before

tightening

104854 Page 5

Operator Installation

Each Operator is labeled Primary or Secondary and the unit case is labeled on each end, either

Primary or Secondary.

Remove an Operator from the box and match it to the proper end of the case.

With the motor end away and slightly below the open edge of the case, insert the operator shaft

through the hole in the bottom of the case.

Carefully lift and turn the motor into the case, being careful not to damage the switches on top of the

operator.

Secure the Operator to the bottom of the case with the 1/4-20 x 1 3/4” Phillips flathead screws

(provided).

Attach the motor ground wire (green) to the back of the case where labeled with the 10-24 x 1/4”

Phillips button head screw (provided).

Connect the white plug of the Operator harness into the control.

Repeat process for opposite side.

With motor / gearbox

perpendicular to enclosure,

insert splined shaft into

shaft hole

Rotate motor / gearbox

to almost horizontal position

being careful not to let switch

assembly hit enclosure

(Note: For clarity, switch wires not shown in views)

Switch Assembly

Rotate motor / gearbox into

enclosure, letting shoulder of

gearbox drop down into shaft

hole. Align screw holes at bottom

& install all 4 screws before

tightening

DO NOT route ANY WIRES

thru enclosure top holes