Salter Brecknell 7550 User Manual

Page 7

5. Material breaks beam of exit photocell…

Weight is displayed and transmitted to a peripheral device.

This scale uses a junction box (J-Box) where the outputs of multiple Weigh

Bars of matching capacities are added together. The J-Box then sends a

single signal to the indicator. These multiple signals must be balanced for

the scale to function properly. This is done at the factory, but these

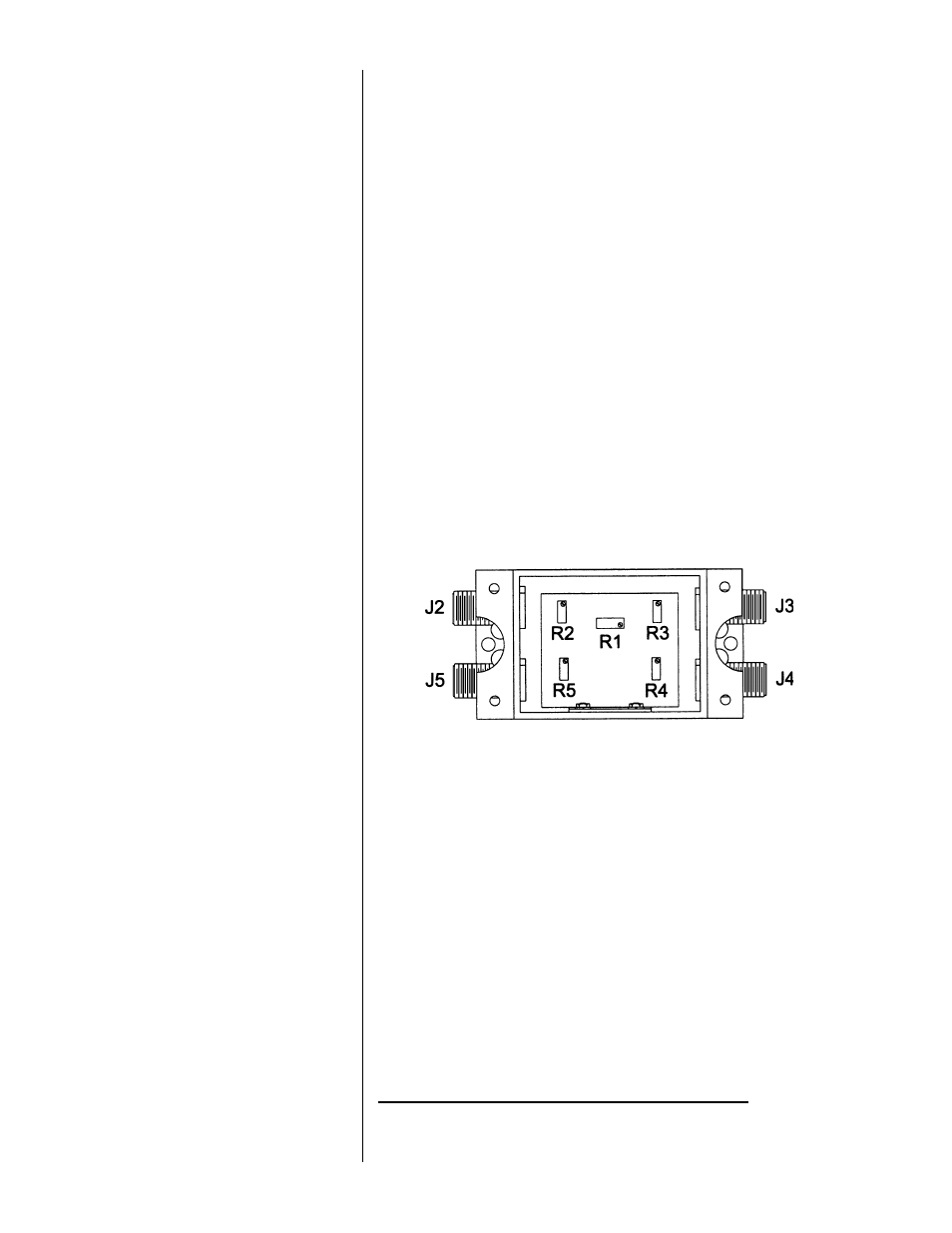

instructions are provided in case they are needed. Figure 1 illustrates the

type of J-Box in the conveyor scale. Each potentiometer affects one weight

sensor. Balance the weight sensors by adjusting potentiometers in the J-

Box as follows:

1. Remove J-Box cover to access potentiometers.

2. Use R1 to set the zero value required by the indicator.

3. Use a test weight that does not exceed the capacity of one weight

sensor, usually 1/4 scale capacity, and obtain a displayed weight

value for the test weight applied to each weight sensor in the scale

system, like this:

a. Place certified test weight directly above first weight sensor.

b. Record displayed weight value.

c. Remove test weight and verify the display returns to zero before

reloading another weight sensor.

d. Repeat Steps a through c for each weight sensor in the scale

system.

4. If displayed weight value for any weight sensor varies from the others

by less than ±1 division, proceed to calibration of the WI-127 if

necessary.

5. If displayed weight value for any weight sensor varies from the others

by more than ±1 division, adjust J-Box potentiometers by turning them

the number of 360° turns indicated by this formula:

Balancing Weigh Bars

Routed Through a

JunctionBox

Figure 1

Weigh Bar J-Box

R1-Course Zero

R2-J2

R3-J3

R4-J4

R5-J5

4

= Number of Turns

Certified Test Weight Value - Displayed Weight Value

Certified Test Weight Value x 0.0028