7550 operation – Salter Brecknell 7550 User Manual

Page 26

7550 Operation

The in-motion system will only weigh and transmit data properly if there is

only one package on the scale at a time with packages identical in size. This

means front edge to front edge spacing of at least the length of the conveyor.

With varying length package applications, there are two criteria which must

be met:

1) With a package on the conveyor scale, the next one coming on the scale

must not break the entrance photocell beam prior to the one on the scale

breaking the exit beam.

2) With a package on the conveyor scale, the exiting package must clear

the exit beam prior to the package entering the scale clearing the

entrance beam.

If either of these rules are violated, erroneous weights may be transmit-

ted or weight values not transmitted at all.

This simple formula will help you figure the minimum package spacing

needed for unequal package sizes.

Package Spacing

Unequal Package Spacing = Conveyor Length + (Longest Package - Shortest Package)

(Front Edge to Front Edge)

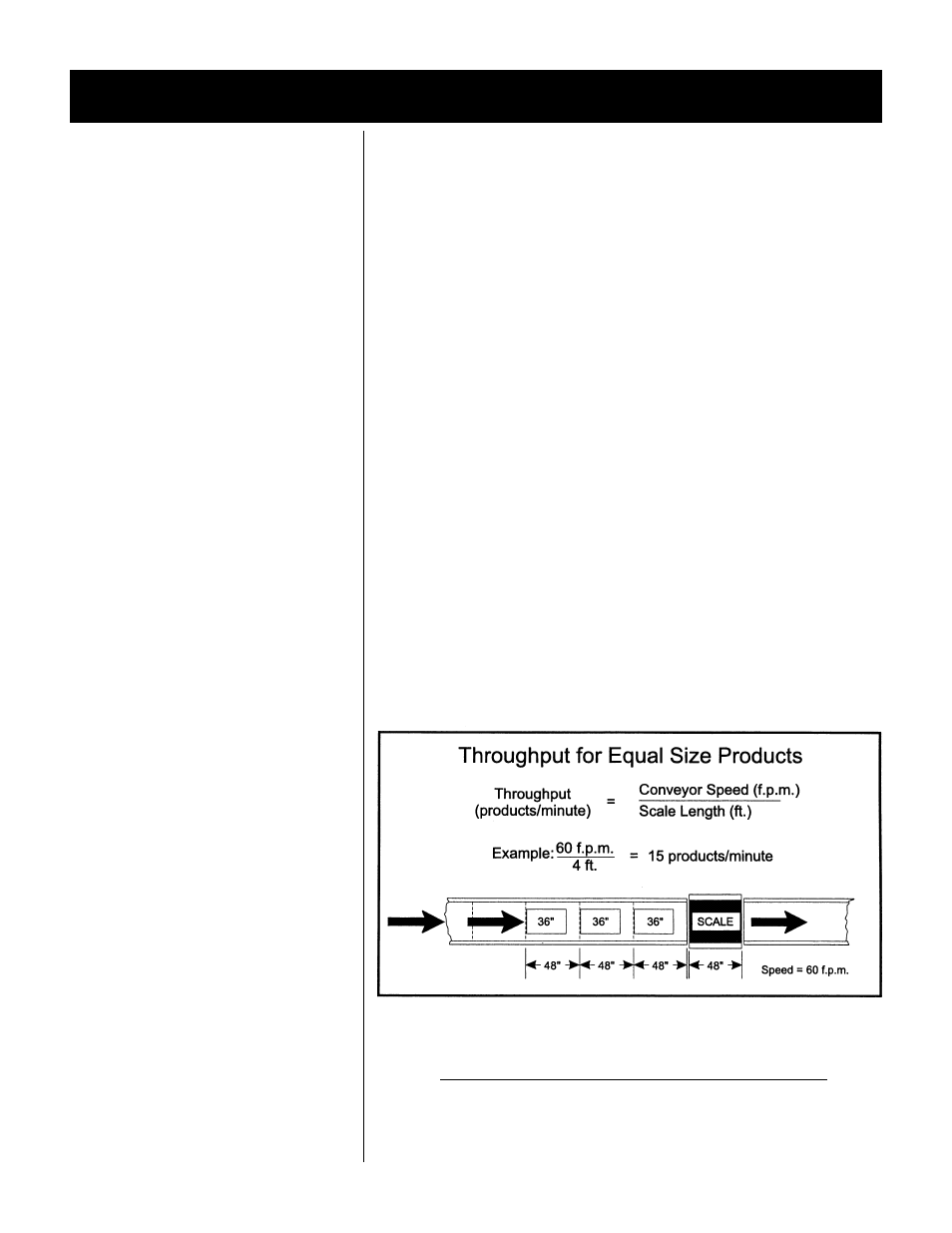

The following diagram shows a formula for figuring throughput of

identically sized packages.

Throughput for Unequal Size P

Throughput for Unequal Size P

Throughput for Unequal Size P

Throughput for Unequal Size P

Throughput for Unequal Size Products

roducts

roducts

roducts

roducts

Belt Speed x 12

Belt Speed x 12

Belt Speed x 12

Belt Speed x 12

Belt Speed x 12

Conveyor Length + Length of Longest Package

Conveyor Length + Length of Longest Package

Conveyor Length + Length of Longest Package

Conveyor Length + Length of Longest Package

Conveyor Length + Length of Longest Package

Length of shortest package

Length of shortest package

Length of shortest package

Length of shortest package

Length of shortest package

23