Warning – Carrier 50TC User Manual

Page 15

15

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

Using unit--mounted convenience outlets: Units with

unit--mounded convenience outlet circuits will often

require that two disconnects be opened to de--energize

all power to the unit. Treat all units as electrically

energized until the convenience outlet power is also

checked and de--energization is confirmed. Observe

National Electrical Code Article 210, Branch Circuits,

for use of convenience outlets.

!

WARNING

Installing Weatherproof Cover: A weatherproof

while-in-use cover for the factory-installed convenience

outlets is now required by UL standards. This cover

cannot be factory-mounted due its depth; it must be

installed at unit installation. For shipment, the

convenience outlet is covered with a blank cover plate.

The weatherproof cover kit is shipped in the unit’s control

box. The kit includes the hinged cover, a backing plate

and gasket.

DISCONNECT

ALL

POWER

TO

UNIT

AND

CONVENIENCE OUTLET. LOCK--OUT AND TAG--OUT

ALL POWER.

Remove the blank cover plate at the convenience outlet;

discard the blank cover.

Loosen the two screws at the GFCI duplex outlet, until

approximately

1

/

2

-in (13 mm) under screw heads are

exposed. Press the gasket over the screw heads. Slip the

backing plate over the screw heads at the keyhole slots

and align with the gasket; tighten the two screws until

snug (do not over-tighten).

Mount the weatherproof cover to the backing plate as

shown in Fig. 27. Remove two slot fillers in the bottom of

the cover to permit service tool cords to exit the cover.

Check for full closing and latching.

RECEPTACLE

NOT INCLUDED

COVER – WHILE-IN-USE

WEATHERPROOF

BASE PLATE FOR

GFCI RECEPTACLE

C09022

Fig. 27 -- Weatherproof Cover Installation

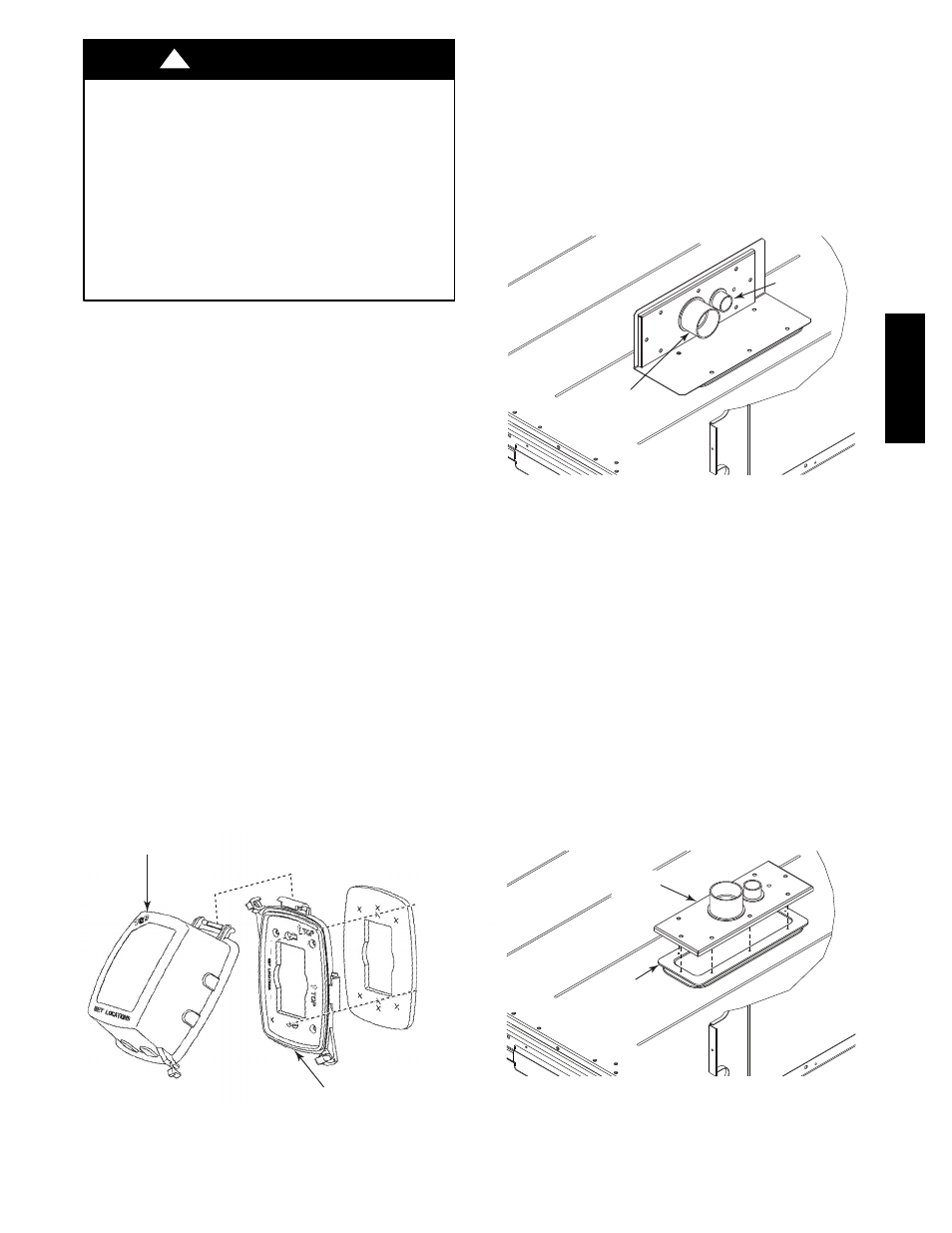

Factory--Option Thru--Base Connections —

This service connection kit consists of a

1

/

2

--in electrical

bulkhead connector and a 1

1

/

2

--in electrical bulkhead

connector, connected to an “L” bracket covering the

embossed (raised) section of the unit basepan in the

condenser section. See Fig. 28. The

1

/

2

--in bulkhead

connector enables the low--voltage control wires to pass

through the basepan. The 1

1

/

2

--in electrical bulkhead

connector allows the high--voltage power wires to pass

through the basepan.

1

/

2

” ELECTRICAL

BULKHEAD

CONNECTOR

1

1

/

2

” ELECTRICAL

BULKHEAD

CONNECTOR

C10907

Fig. 28 -- Thru--the--Base Option, Shipping Position

1. Remove the “L” bracket assembly from the unit.

2. Remove connector plate assembly from the “L”

bracket and discard the “L” bracket, but retain the

washer head screws and the gasket (located between

the “L” bracket and the connector plate assembly).

NOTE: Take care not to damage the gasket, as it is

reused in the following step.

3. Place the gasket over the embossed area in the

basepan, aligning the holes in the gasket to the holes

in the basepan. See Fig. 29.

4. Install the connector plate assembly to the basepan

using 8 of the washer head screws.

NOTE: If electrical connections are not going to occur at

this time, tape or otherwise cover the fittings so that

moisture does not get into the building or conduit in the

interim.

GASKET

CONNECTOR

PLATE

ASSEMBLY

C10908

Fig. 29 -- Installing Thru--the--Base Option

Check tightness of connector lock nuts before connecting

electrical conduits.

50TC

--

*16