Warning, Caution, General information – Qmark CHPR25 - Compact Freeze Protection Heater User Manual

Page 2: Mounting

GENERAL INFORMATION

Model CFP25 is designed, tested and Listed by Intertek

Testing Services NA, Inc. (ETL/C-ETL Listing Mark) to comply

with the following standards:

USA: ANSI/UL 1995 titled “Heating and Cooling Equipment”

Canada: CSA C22.2 No. 236-05, third edition titled “Heating

and Cooling Equipment”

This unit is specifically designed and approved for freeze pro-

tection installations into a concealed space and other areas not

readily accessible. Typical applications include plenums and

associated plenum spaces (such as areas above a finished

ceiling that contain utilities), crawl spaces, water closets and

other concealed locations where freeze protection is required.

Note: rated static pressure is 0.20” sp . This unique heater is

provided with a set of normally open contacts that can supply a

line voltage signal to an alarm device if desired to provide early

notice if for any reason the heater cycles off on its built-in over

temperature safety control. This can provide an early notifica-

tion to allow for repairs BEFORE a freeze up occurs

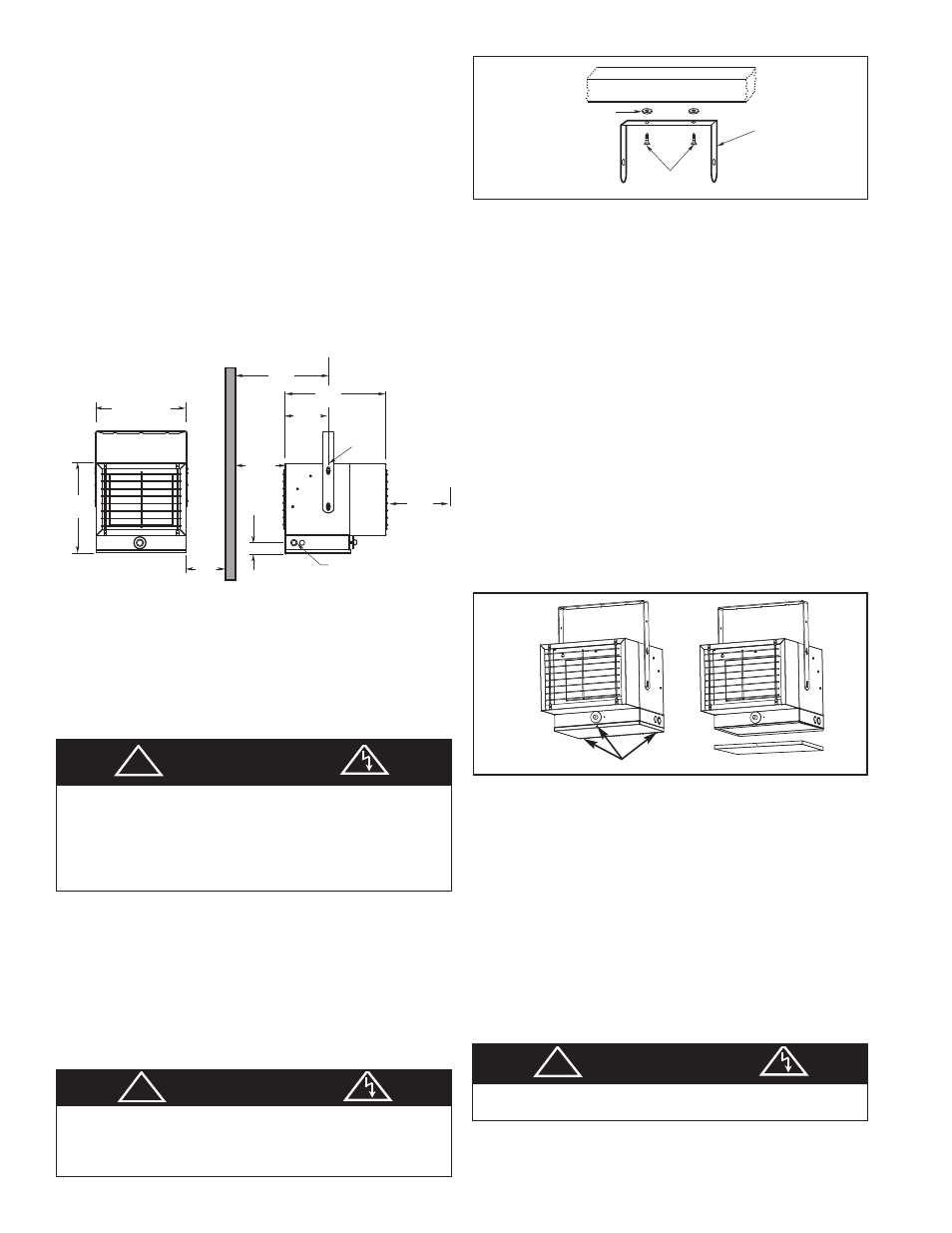

Minimum Installation Clearances (See Figure 1)

SIDES, TOP AND BOTTOM

0 IN.

REAR:

7-3/8 in. (187 mm)

FRONT:

24 in. (610 mm)

Note: To access field wiring and heater controls requires the

bottom panel door open as shown in Fig. 3. Consideration

must be given to provide access to this panel.

MOUNTING

This heater can be mounted using the mounting bracket

provided with the heater or it may be mounted using the 1/2” -

13NC threaded hole provided on the top of the heater.

Mounting The Heater With Bracket

1. Remove the bracket from the heater and position to the

desired mounting location (see Figure 2). Securely attach to

the building structure using appropriate hardware (supplied

by others).

2. Attach heater to bracket using the keyhole slots in bracket

and bolts provided with heater. Position heater as desired

and tighten bolts.

Mounting The Heater With Threaded Rod

1. A 1/2”-13NC threaded hole is provided in top of heater

enclosure for mounting the heater if desired. Optional

mounting brackets are available from your electrical dis-

tributor for use with this heater. If one of these brackets is

to be used, refer to the instructions provided with the

bracket.

2. If a threaded rod is used, it must be securely attached to

the building structure using appropriate brackets, washers,

nuts and lock washers to secure the heater properly and

prevent it from falling (see Warning No. 6, page 1).

3. When installing threaded rod into heater, make sure rod is

inserted approximately 1” into heater to assure all threads

are engaged. In addition, a 1/2” nut should be used as a

jam nut to prevent the heater from rotating during opera-

tion.

Connecting the Power

1. To connect the power to the heater, simply remove the

three screws from the bottom of the unit. This allows the

cover to be removed, providing access to the electrical

wiring and connectors. (See Fig. 3)

2. Attach the cable connectors to the unit and slide 10 gauge

wire or appropriate size for amperage marked on the

heater nameplate and length of run per NEC (National

Electrical Code) through the cable connector. Pull enough

of the wire through the connector to work with when mak-

ing the connections.

3. Connect the wire to the power terminal block located in

the base of the heater (See Figures 4 and 5).

Note: This unit is provided with two 1/4” male quick connect

terminals (see Wiring Diagram, Figure 4) marked as Alarm

1 and Alarm 2, to allow for an external alarm to be con-

nected to the unit if desired. This option can provide notifi-

cation if the heater overheats and cycles on the thermal

over-temperature limit. Each terminal (Alarm 1 or Alarm 2)

will provide 120 volts to ground. Connection to both Alarm

1 and Alarm 2 terminals will supply line voltage (208 or

240V) to the alarm.

4. Close the wiring compartment and replace the screw and

turn on the power at the main service.

SIDE VIEW

MOUNTING

LOCATION

M

INTAKE

1

/

2

3

/

4

3

/

4

in.,

in. (2)

(13 mm, 20 mm)

14 in. (356 mm)

12

1

/

2

in.

(318 mm)

FRONT VIEW

14 in.

(356 mm)

7

3

/

8

in.

(187 mm)

5

1

/

2

in.

(140 mm)

13 in.

(330.2 mm)

(0 mm)

24 in.

(610 mm)

0 in.

1

in.

(45 mm)

MINIMUM DISTANCE

TO WALL

MINIMUM

DISTANCE

FROM

DISCHARGE

TO ANY

OBJECT

Figure 1 Dimension Data

WARNING

TURN OFF ALL ELECTRICAL POWER TO UNIT BEFORE

PERFORMING ANY MAINTENANCE OR SERVICE ON UNIT.

(UNLESS SPECIFIC TESTS REQUIRE ELECTRICAL

SUPPLIES.) FAILURE TO TAKE THIS PRECAUTION MAY

RESULT IN PERSONAL INJURY OR DEATH DUE TO

ELECTRICAL SHOCK.

!

CEILING JOIST

WASHER

3

/

8

" DIAGONAL

LAG BOLT

BRACKET

Figure 2

Double-Screw Mounting

Figure 3

REMOVE SCREW TO OPEN DOOR

CAUTION

TO PREVENT DAMAGE TO THE ALARM DEVICE, IT MUST BE

SUITABLE FOR VOLTAGE AS NOTED ABOVE.

!

CAUTION

TWO EACH, MIN. 3/8” DIA. MOUNTING BOLTS (OR LAG

BOLTS), FLAT WASHERS, LOCK WASHERS, AND NUTS AS

NECESSARY MUST BE USED SO THE HEATER WILLNOT FALL

- SEE WARNING NO. 6.

!