3 filtering techniques, 4 industrial vs. oiml and ntep modes, Calibration counter – Cooper Instruments & Systems DFI 250X Digital Weight Indicator User Manual

Page 17

CF 147

13

version 1.1

Since the instrument

uses 5V load cell

excitation, the absolute

signal voltage is:

Absolute Signal Voltage

= Excitation Voltage x Full Scale Signal = 5V x 1.0mV/V = 5.0mV

Calculating the

signal resolution:

Signal Resolution =

Absolute Signal

Voltage

Number of

Graduations

=

5.0mV

1000

divisions

= 0.005mV/division = 5 µV/division

6.3 Filtering Techniques

There is a trade off between noise filtering and the step-response time of the system. The step-response is defined

as the time between placing a weight on the scale and the correct stable weight reading being displayed. This does

not affect the number of readings per second that are taken. It simply defines the amount of time that is required to

determine a final weight reading.

The FILTER setting in the instrument setup shows the amount of time over which the averaging is taken.

Increasing the averaging time will result in a more stable reading but will extend the time it takes the instrument to

settle to a final reading. Refer to FILTER (Reading Average) section 7.4.2.

6.4 Industrial vs. OIML and NTEP Modes

The instrument may be operated in Industrial, OIML or NTEP mode. (Note: For NSC requirements use the OIML

setting.) The OIML and NTEP modes restrict certain aspects of the operation of the instrument to ensure

compliance with the respective trade certified standards. For more information refer to the Calibration Counter

section below and also to the USE (Scale Use)

section 7.4.2 for setup information. The following table lists the

operation differences for each of these modes.

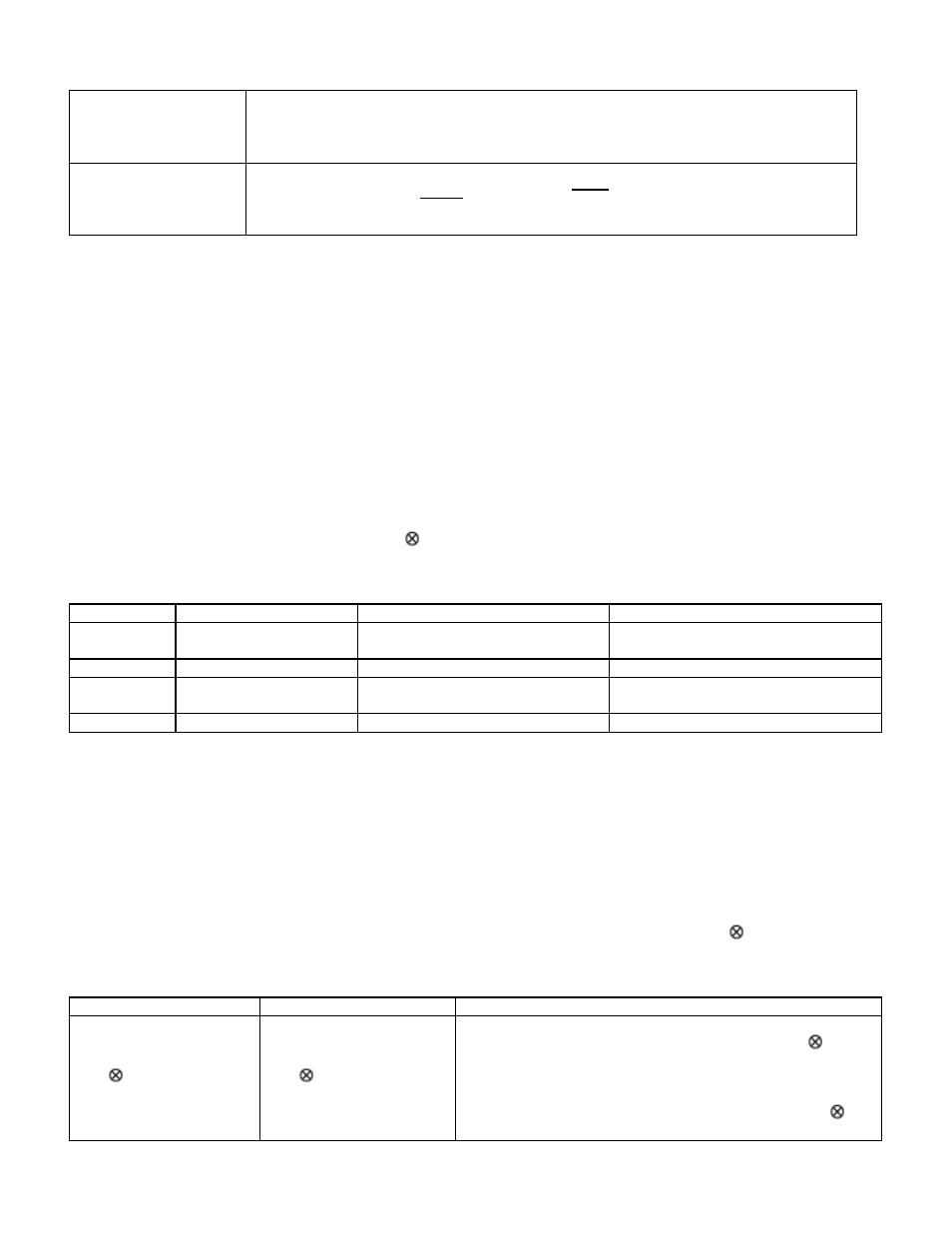

Table 2: Industrial vs. OIML and NTEP Modes

Element

Industrial

OIML

NTEP

Underload

–105% of full scale

–1% or –2% of full scale

depending on zero range setting

Same as OIML

Overload

105% of full scale

Full scale +9 divisions

105% of full scale

Tare

No restrictions on Tare

Tare values must be > 0

Tare values must be > 0 and

rounded to the nearest graduation

Test Modes

Unlimited time allowed

Limited to five seconds

Limited to five seconds

6.5. Calibration Counter

Within Setup there are a number of critical steps that can affect the calibration and/or legal for trade performance of

the instrument. If any of these steps are altered, the trade certification of the scale could be voided.

The instrument provides built-in calibration counter(s) to monitor the number of times the critical steps are altered.

The value of a counter is stored within the instrument and can only be reset at the factory. Each time a critical step

is altered, the counter will increase by one. Whenever the instrument is powered up, or setup mode is entered/

exited, the current value in the counter is displayed briefly (e.g. C00010).

Note: When the Scale Use is set to NTEP two counters will display. Refer to USE (Scale Use)

section 7.4.2 for

setup information. The table below describes when the counter(s) will increment for Industrial, OIML or NTEP

modes.

Industrial

OIML

NTEP

The Calibration Counter

increments when trade

critical settings, marked

with

, are changed. An

example of the counter is

C.00019.

The Calibration Counter

increments when trade

critical settings, marked

with

, are changed. An

example of the counter is

C.00019.

The Calibration Counter increments when trade critical

settings in the Calibration (CAL) menu, marked with

, are

changed. An example of the counter is C.00010.

The Configuration Counter increments when other trade

critical settings (i.e. not in the CAL menu), marked with

,

are changed. An example of the counter is F.00009.