Maintenance, In-line hydraulic filter, Installation reference information – Great Plains V300 Assembly Instructions User Manual

Page 23: Connector identification

Great Plains Mfg., Inc.

Installation Instructions

23

11/08/2006

148-771M

Maintenance

In-Line Hydraulic Filter

If raising or lowering times slow noticeably, check the in-

line filter, and clean as necessary.

To clean the filter:

1.

Set tractor’s opener down-force hydraulic circuit to

float.

2.

Shut down tractor.

3.

Loosen connections at the in-line filter and allow a

few minutes for drain-back.

4.

Disconnect and cap the hose to the filter.

5.

Disassemble the filter in place.

6.

Remove the 50 micron screen. Wash with solvent

and use compressed air to dislodge any debris.

Note: If the filter screen needs to be replaced, order an

810-553C from your Great Plains dealer.

7.

Reassemble filter and reconnect hose.

8.

Complete a hydraulic system purge and re-phase

per your Operator’s manual.

Installation Reference Information

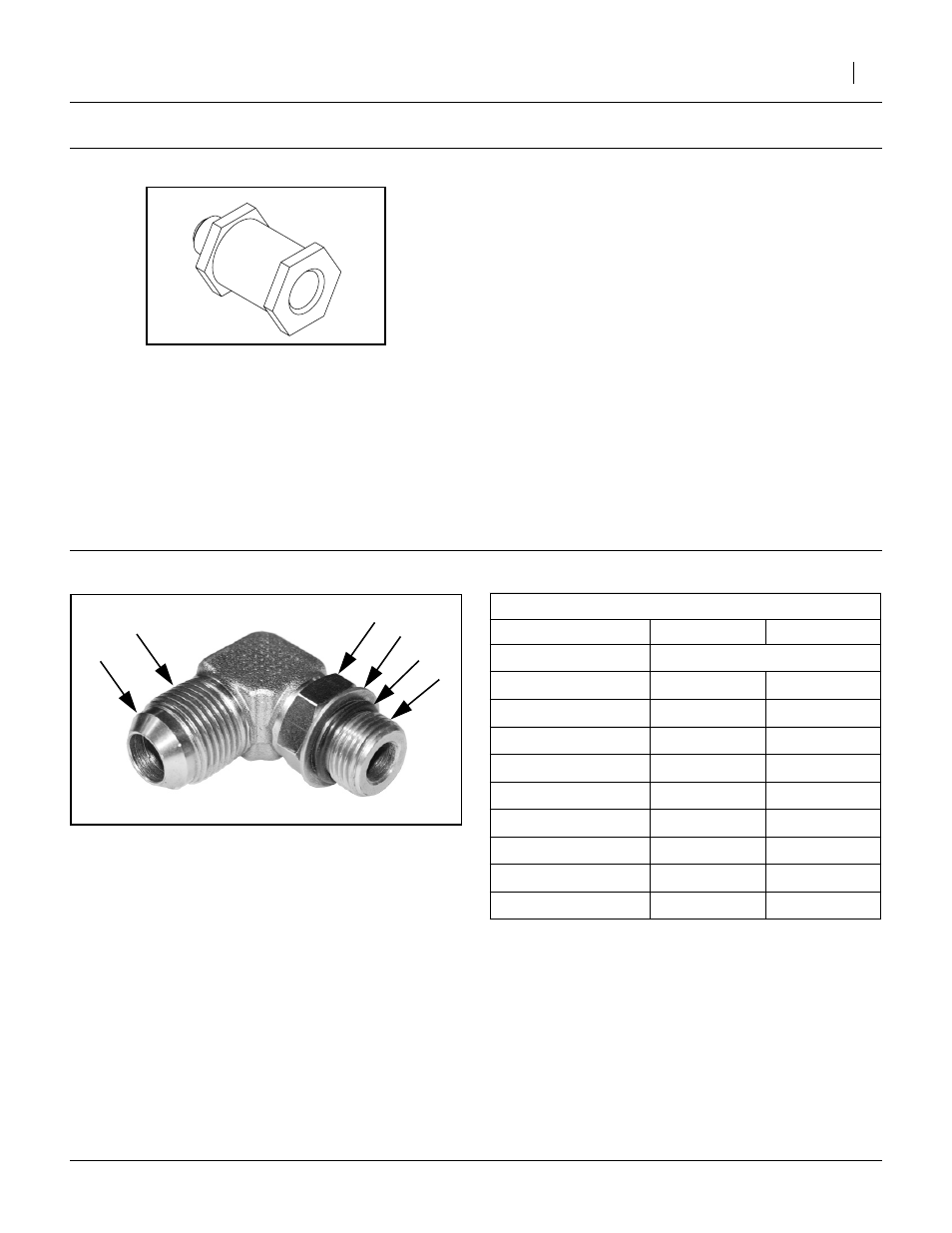

Connector Identification

➀

JIC - Joint Industry Conference (SAE J514)

Note straiight threads

➁

and the

37

° cone

➂

on “M” fittings (or 37

° flare on “F”).

➃

ORB - O-Ring Boss (SAE J514)

Note the straight threads

➄

and,

elastomer O-Ring

➅

.

Fittings needing orientation, such as the ell above,

also have a washer

➆

and

jam nut

➇

(“adjustable thread port stud”)

-

NPT - National Pipe Thread (not shown)

have tapered threads, no cone/flare, no O-ring.

25187

➀

➁

➂

➃

➄

➅

➆

➇

25188

Torque Values

Fastener/Fitting

Ft-Lbs

N-m

1

⁄

4

NPT

1.5-3.0 turns past finger tight

1

⁄

4

-20 GR5

8

11

3

⁄

8

-16 GR5

31

42

1

⁄

2

-13 GR5

76

105

9

⁄

16

JIC

18-20

24-27

9

⁄

16

ORB w/jam nut

12-16

16-22

9

⁄

16

ORB straight

18-24

24-32

3

⁄

4

JIC

27-39

37-53

3

⁄

4

ORB w/jam nut

20-30

27-41

3

⁄

4

ORB straight

27-43

37-58