Operation, Closed center field operation – Great Plains V300 Assembly Instructions User Manual

Page 19

Great Plains Mfg., Inc.

Installation Instructions

19

11/08/2006

148-771M

Operation

Closed Center Field Operation

The openers are mounted on floating opener frames

which follow the contour of the ground while maintaining

constant opener down pressure.

1.

Lower the opener frames by pushing FORWARD on

the tractor remote hydraulic lever. The remote lever

must be LOCKED OPEN in this position to provide

constant pressure/flow to the openers.

John Deere tractors with Sound-Gard ® Body:

Use lever lock clip, John Deere part number

R52667, to lock lever forward. See your tractor

dealer for clip purchase and installation.

John Deere 7000 Series tractors: Rotate valve

detent selector to motor position to lock lever in for-

ward position.

John Deere 8000 Series tractors: Set timer to con-

tinuous. Push lever forward until detent clicks.

Case-IH Magnum tractors: Lock lever forward in

detent position. You may need to turn up detent

pressure to its maximum setting. Do not tie hydraulic

lever past detent position with a strap. See your trac-

tor dealer for hydraulic-system details.

Other tractors: Lock lever forward in detent posi-

tion. You may need to turn up detent pressure to

maximum or use a mechanical detent holder to hold

lever forward. See your tractor dealer for proper

means of providing constant flow to openers.

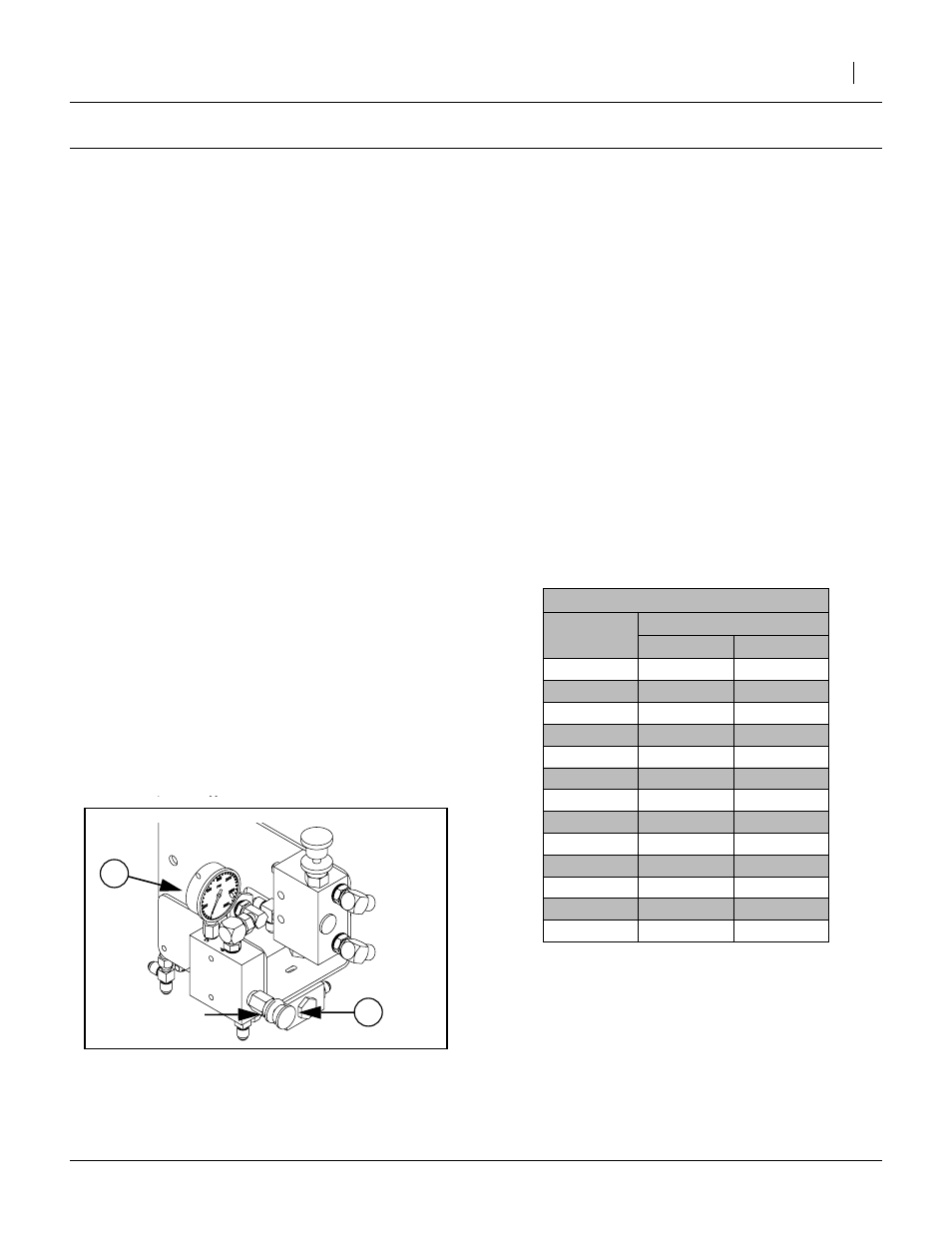

2.

With the tractor hydraulic lever locked forward,

release the lock disk

➀

, turn the knob on the pres-

sure control valve (44) as shown in Figure 27. Watch

the pressure gauge (43) and dial in the desired pres-

sure on the openers. Clockwise increases the pres-

sure and counterclockwise decreases pressure.

Once the pressure is set, lock the knob with the lock

disk

➀

.

Note: Refer to “Post-Installation Lift Cycle” on page 17

to know what to expect the drill to do as hydraulics

are cycled.

The recommended pressure range for drilling is between

200 psi and 1400 psi. Setting the opener down pressure

above 1600 psi will raise the drive wheels off the ground

when the seed box is empty causing skips and poor seed

metering. See the following table for the relationship

between psi and down force.

The following down-forces are per-opener, with no extra

weight on the hangers (at the lower down-force values).

Higher down-force values may require weights on the

hangers. Consult the Operator’s Manual for further infor-

mation.

Figure 27

Closed Center Valves

25185

➀

Adjustment Valve Table

System

PSI

Down Force

Pounds

Kg

200

62

137

300

77

170

400

84

185

500

96

212

600

110

243

700

123

272

800

139

306

900

155

341

1000

173

380

1100

194

427

1200

217

479

1300

249

548

1400

268

591