Cart inlet strainer, Filter removal, Filter cleaning – Great Plains SML1000 Operator Manual User Manual

Page 31: Filter removal filter cleaning

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

27

03/31/2011

407-451M

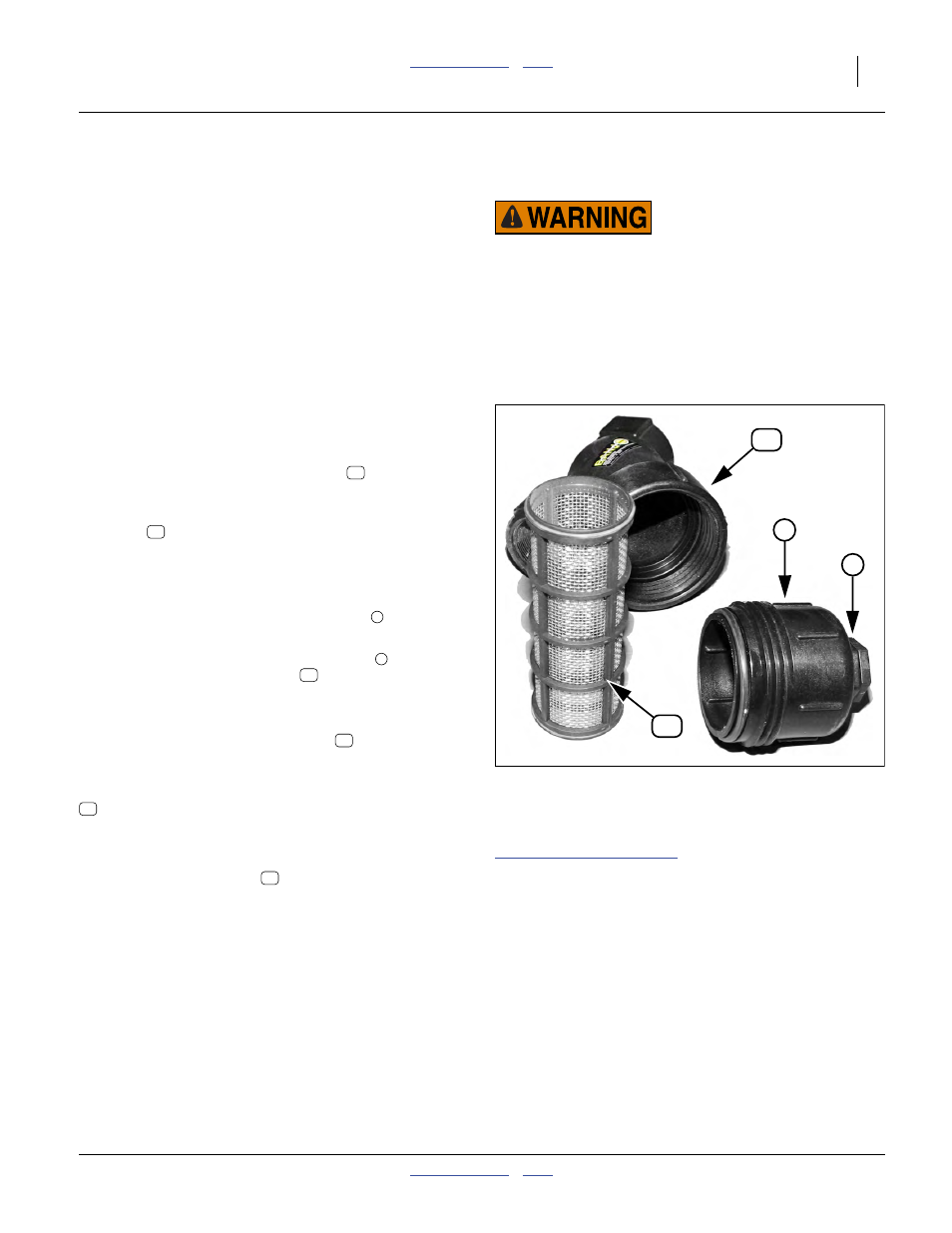

Cart Inlet Strainer

Refer to Figure 16

The cart uses an in-line strainer to keep damaging par-

ticulates out of the system, and reduce the workload of

the strainer at the pump (which has a smaller screen

size).

The inlet strainer becomes clogged over time, reducing

material loading rate. Plan to clean the strainer several

times per season. Don’t wait for loading problems to

arise. Higher quality liquid fertilizers may require less fre-

quent cleaning.

Disassemble and clean the strainer prior to storage to

prevent caking.

Filter Removal

1.

For the SML-1000 Gallon Cart or the SML-500 Gal-

lon Cart, the tank must be empty for inlet filter

removal. The tank discharge valve

the cart outlet line and not the inlet line.

1.

For the SML-750 Gallon Cart, close the discharge

valve

. The tank does not need to be empty.

2.

Place a pail or bucket under the filter. It will be full of

fluid. The hose line from inlet shut-out valve to tank

may also contain fluid.

3.

Unscrew and remove the canister cap

. Drain the

fluid. Be careful to preserve the small gasket.

4.

Unscrew and remove the canister body

. Be careful

to preserve the filter screen

screen gaskets and

large canister gasket.

Filter Cleaning

Replacement parts for the 831-040C

are available

from Banjo Corporation and their authorized resellers.

The filter screen is available from banjo or Great Plains.

The Great Plains part is:

LS212 BANJO SCREEN FOR 831-040C

5.

Inspect O-ring gaskets. Replace gaskets if torn or

excessively worn.

6.

Inspect filter cartridge

(which also has O-ring

gaskets) Wash the filter cartridge with water, or

replace with new cartridge if necessary. Replace if

screen is separated, torn, punctured, or build-up

cannot be removed.

7.

Reinstall the cartridge, canister, and plug cap.

MetaData: End of

Null4:

Replacement parts:

Figure 16

831-040C Inlet Filter

31508

1

2

53

48

Possible Chemical Hazard:

Wear gloves and proper protective equipment as required by

chemical manufacturer. Filter cleaning will result in hand con-

tact with fertilizer. Avoid prolonged breathing of chemical

fumes. Wear respirator as required by chemical manufacturer.

Some chemicals will cause serious burns, lung damage, and

death. Avoid contact with skin or eyes. Seek medical assistance

immediately if accident occurs. Know what to do in case of an

accident.

1

48

53

48

48