Troubleshooting – Great Plains SML1000 Operator Manual User Manual

Page 27

03/31/2011

407-451M

Great Plains Manufacturing, Inc.

23

Troubleshooting

See also the Troubleshooting sections of the implement Operator manual, and the Seed Rate manual.

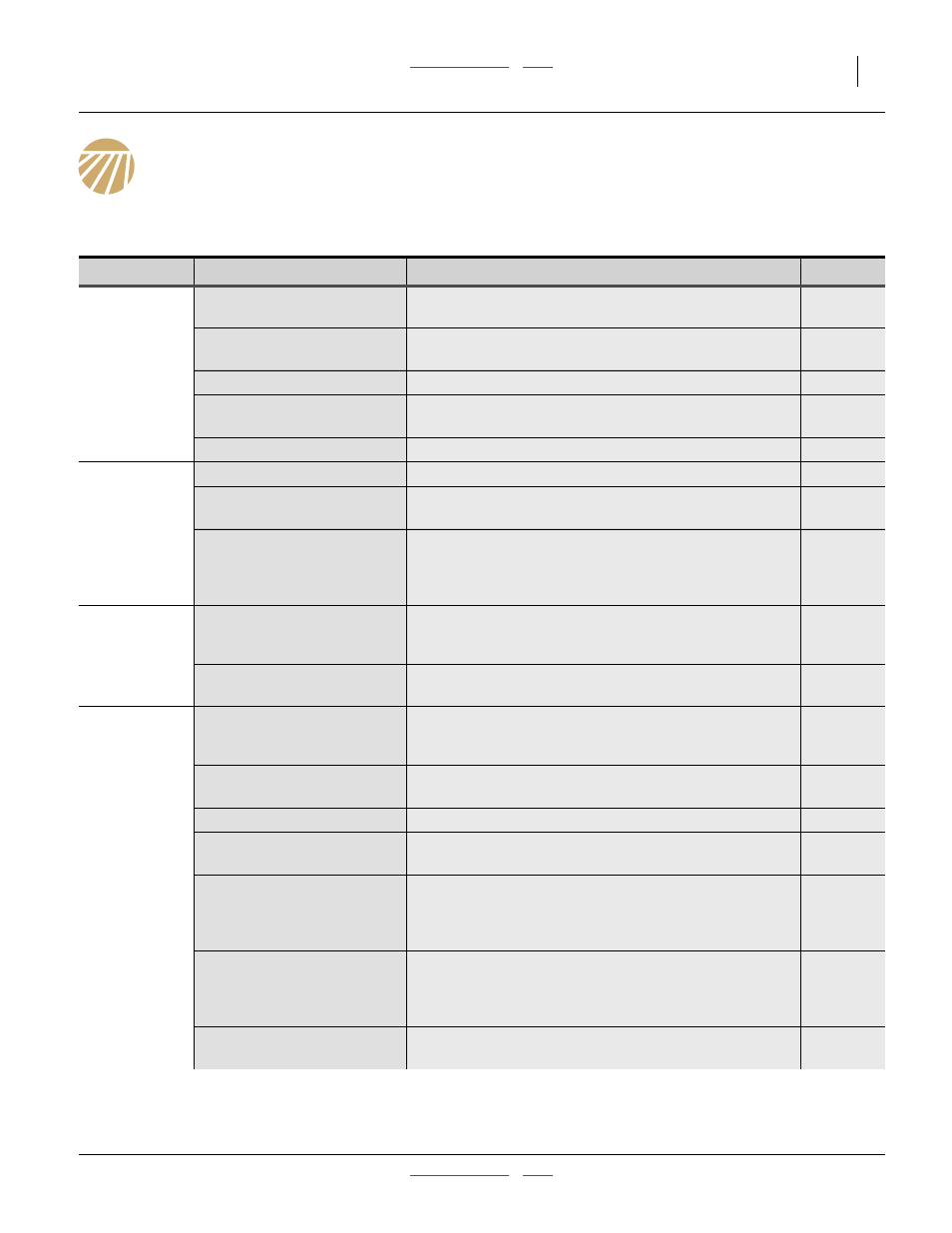

Fertilizer Cart Troubleshooting

Problem

Cause

Solution

Page(s)

No Load

Inlet valve and/or 735 gallon

tank discharge valve closed

Open valve(s).

Insufficient pressure at

source

Elevate source or use pump.

Inlet filter completely clogged Clean filter.

In cold weather, inlet plumb-

ing may be frozen

Move cart to warm space or wait for warmer weather.

Slow Load

Inlet filter partially clogged

Clean filter.

Insufficient pressure at

source

Elevate source or use pump.

Solids in mix too large for

inlet filter

Reconsider using this material. Although you could top-

load it, or replace the 12 mesh filter with a 6 mesh, no

standard orifice plate sizes are apt to be large enough

to pass this material at the row drops.

Tank Level

Lower at

Field

Material sloshed out breather

vent in transport

Fill tank at field, or to less than half full prior to transport,

and/or drive slower, brake more gently or chose a

smoother route.

Leak due to damaged or

loose hose/fitting

Inspect entire cart plumbing system for leaks. Repair as

needed.

No Flow in

Field

Pump not yet primed

Prime the pump. Otherwise, at low application rates, it

may take some time/distance to clear the air from a

completely dry implement inlet and boom system.

One or more valves closed

Check that tank discharge, cart outlet and implement

inlet valves are all open.

Material depletion

Stop and check sight gauge

Pump strainer completely

clogged

Clean pump strainer. Also check mesh size vs. material

requirements.

Pump inoperative

Check pump sprockets, chain, range and scale setting.

Check for internal pump failure. For a pump other than

Great Plains ground drive, also check monitor settings,

cable harness, fuses, clutches, etc.

Cold weather: material too

viscous for strainer and/or

orifice plates. Material might

be entirely frozen.

Wait for warmer weather. Increasing pump strainer

mesh and orifice plate sizes to compensate for cold gel-

ling may produce uneven application rates.

All material dumping at relief

valve

Check and adjust the relief valve. If not set too low, ori-

fice size is likely to small for material viscosity or solids.