Great Plains SML1000 Operator Manual User Manual

Page 28

24

SML-1000, SML-750, SML-500

Great Plains Manufacturing, Inc.

407-451M

03/31/2011

a.

See Seed Rate manual for relief valve pressure range and adjustment.

MetaData: End of “Troubleshooting”

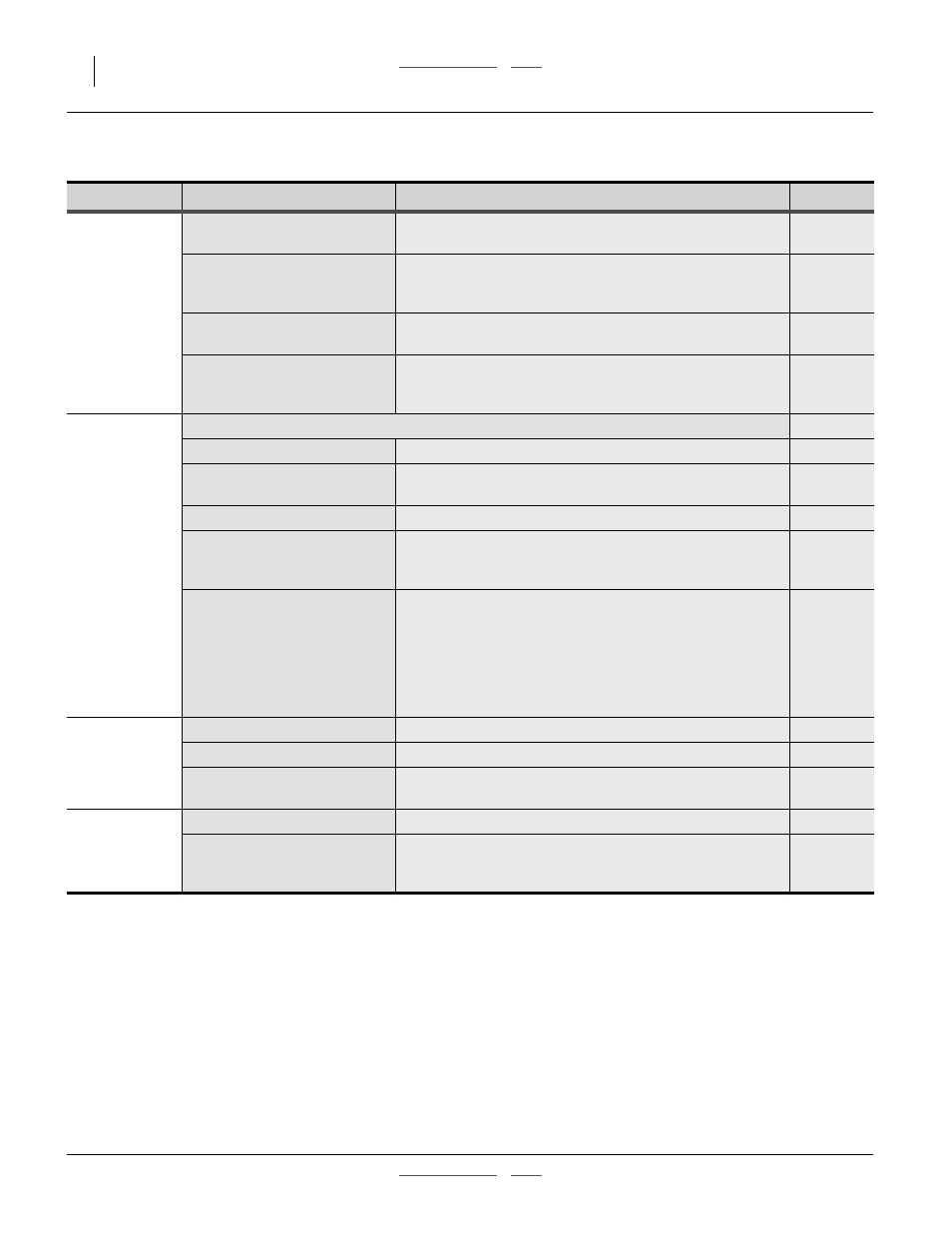

Material

Dumping

Orifice size too small for

material or rate

Re-check orifice plates against Seed Rate manual

guidelines.

Speed too high

Gallons/acre or liters/ha is correct, but speed is too high

for orifice plate size. Slow down or recalculate for speed

actually used.

Relief valve set too low

Check and adjust the relief valve. If not set too low, ori-

fice size is likely to small for material viscosity or solids.

Pump strainer clogged or

mesh size too fine for mate-

rial

Inspect pump strainer. Clean filter mesh. Check size

against material requirements.

Low Flow

But no material is dumping...

Pump drive in Low Range

Exchange sprockets

Valve not fully open

Check tank discharge, cart outlet and implement inlet

valves. Align handles with hose.

Ground drive wheel slipping

Wait for dryer conditions

Rate setting calculation (or

pump range/scale setting)

incorrect

Re-check field size, swath, speed, pump setup and ori-

fice plate sizing.

Pump wearing

This check for positive displacement pumps only:

With implement lowered and stopped, and tank over

half full, disconnect fitting at pump outlet. Once fluid

already present in fitting drains off, flow should stop.

If material continues to flow, even at a very low rate,

it indicates bypass in the pump. Repair or replace the

pump.

Erratic

Gauge

Reading

Air in lines

Prime pump or wait for pump to clear air.

Failed gauge

Replace gauge.

Cold weather: material too

viscous for accurate reading

Wait for warmer weather.

High Flow

Pump drive in High Range

Exchange sprockets

Rate setting calculation (or

pump range/scale setting)

incorrect

Re-check field size, swath, speed, pump setup and ori-

fice plate sizing.

Fertilizer Cart Troubleshooting

Problem

Cause

Solution

Page(s)