Tweco Troubleshooting Power Supply User Manual

Page 9

9

Causes for 1-4 code:

• Cut demand set much lower than recommended for torch parts, i.e. 100A

consumables in torch but cut current set for 30 or 50A (or zero). Current may

be too low to keep arc on.

• Torch standoff too high for cutting process being used.

• Preflow gas flow to low due to a leak somewhere between the preflow

regulator and the torch? Check for leaks.

• Remote analog current control switches set wrong.

If remote analog current control is being used (SW8-2 (CCM CPU PCB)

is on and SW11 (CCM I/O PCB) is set to “A” (down) position) but no analog

voltage connected to TB1-10, then cut demand will be zero, pilot will be

weak, depending on torch height it may still transfer but will immediately go

out.

If remote analog current control is not being used but either SW11 is set to

“A” or SW8-2 is on also results in zero cut demand.

If system is Autocut with GCM 1000, current control is analog voltage

from the GCM 1000 front panel pot.

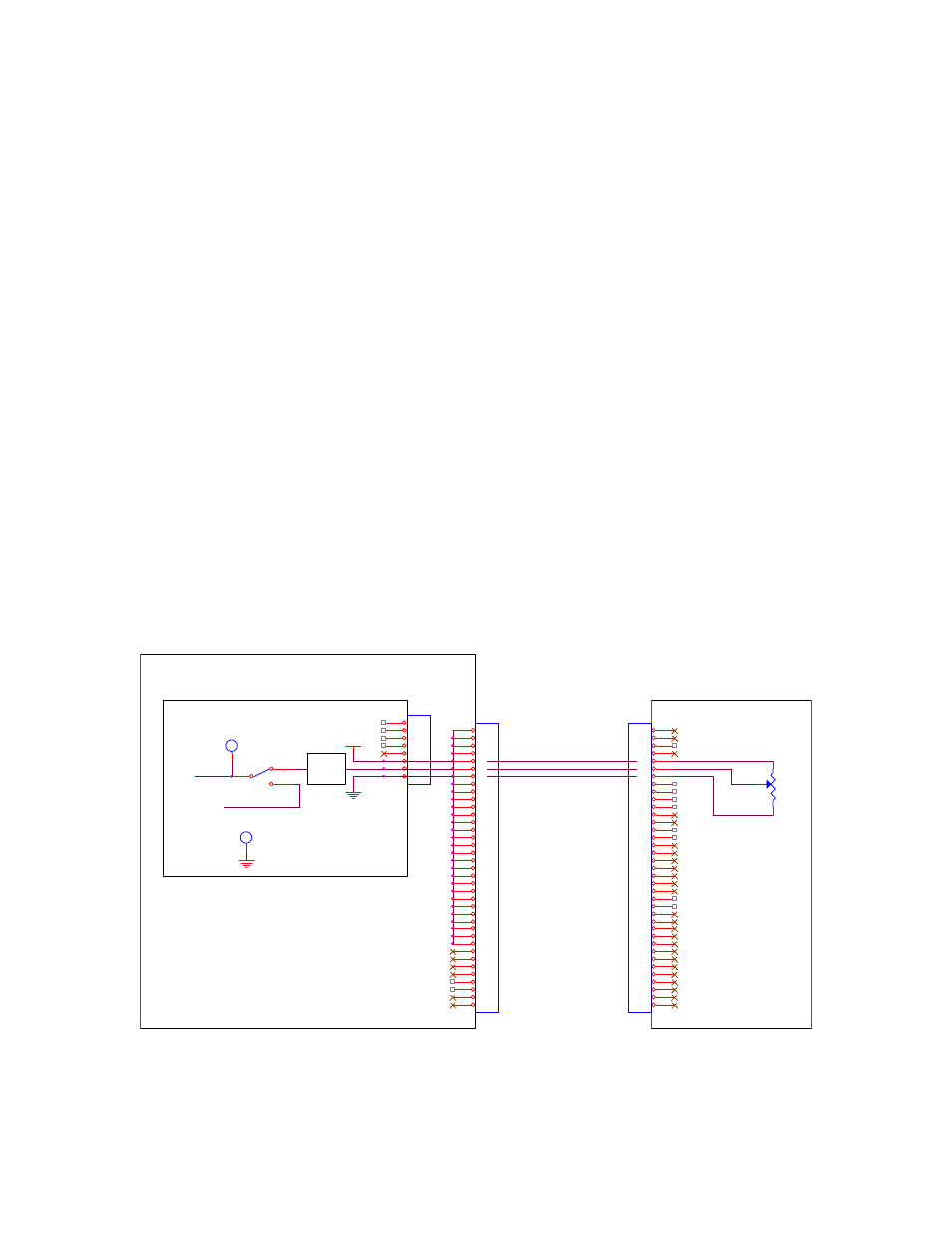

SW8-2 should be off and SW11 set to “B” (up) position. With pot at max,

check for 3.3V on CCM I/O PCB TP9 (TP1 common). While turning pot

toward min TP9 voltage should vary linearly to zero V.

TP9

1

2

3

SW11

SPDT

1

2

3

4

5

6

7

8

J7

Divide

by 3

0-3.3V

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(8)

(10)

(10)

(9)

+10VDC

(9)

POWER SUPPLY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

J55

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

J59

1

2

3

CURRENT CONTROL POT

GCM 1000

TP1

CCM