Tweco Troubleshooting Power Supply User Manual

Page 36

36

is pin 5 of the ribbon cable. Common is also available on at TP0 on PCB5 or TP1

on CCM I/O PCB.

No flow, either actual or failure to sense flow, is most likely to set code 4-4

unless something fails after power up purge. If flow sensor or PCB fails after

purge, you normally would try recycling power so again it would set 4-4.

Possible causes for low flow.

• Coolant filter (internal or external) clogged.

• Coolant supply or return hose twisted or pinched reducing flow.

If coolant flow in not low but code is being set, possible causes:

• Sensor disconnected

• Defective flow sensor

• PCB5

• CCM

See section code 4-4 for troubleshooting details.

Note -- Code 4-2 combined with 2-4 & 3-4 when the Plasma Enable on the

GCM 2000 or 2010 gas control is set to disable can indicate a fault in the CCM

I/O PCB. When switching back to Enabled the pump will not restart so continues

to display 4-2 indicating no coolant flowing.

Normally the code during a disable should be 1-1. Circuits on the I/O PCB

detect the Plasma Enable is disabled and send signal to the microcontroller in the

CCM. If that signal doesn’t get passed the microcontroller doesn’t know system is

disabled so sets these 3 codes.

4-3

Coolant Overheated

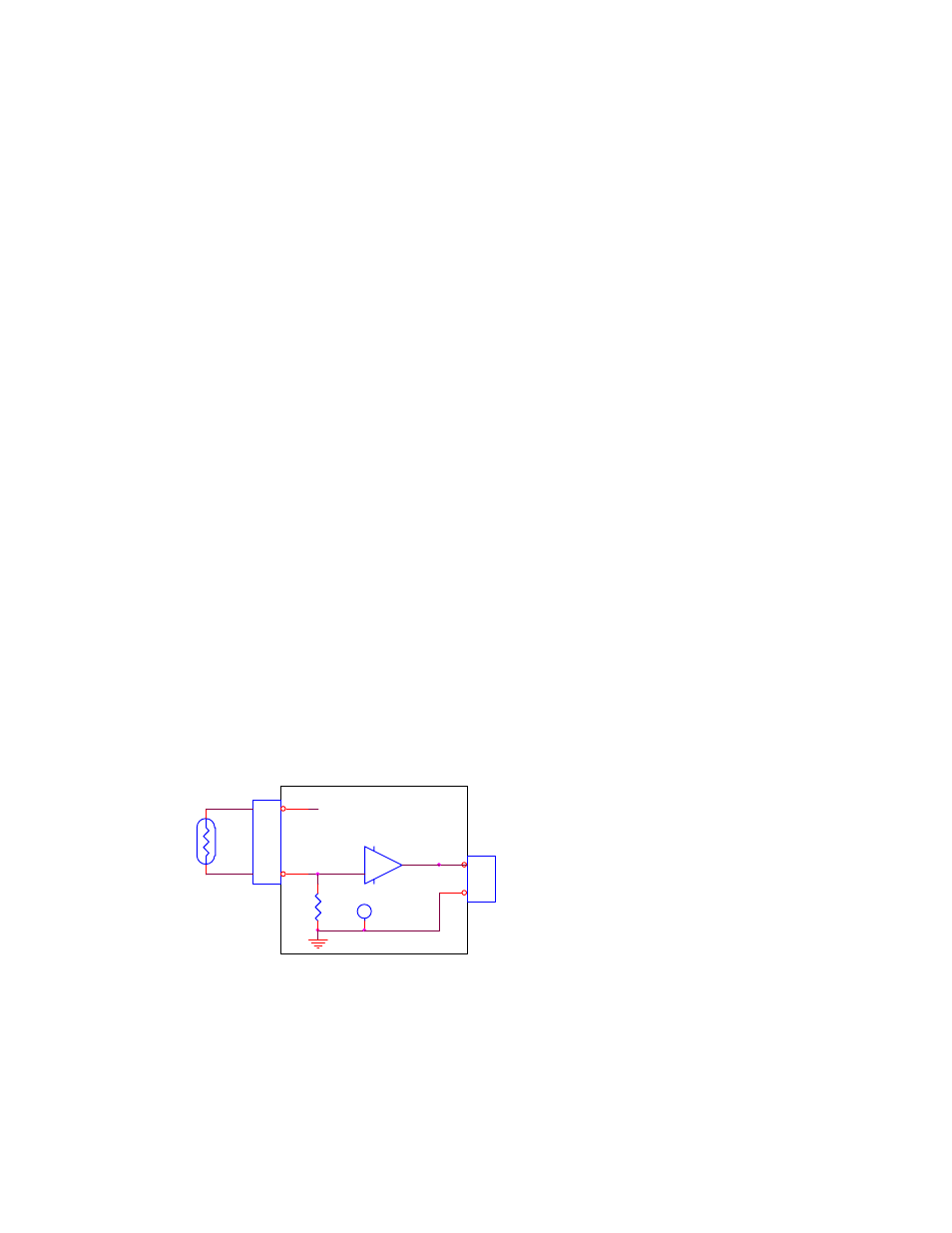

TH1 is a linear negative temperature coefficient resistor sensor attached to the

brass fitting where the torch coolant return enters the power supply rear panel.

It forms the upper part of a voltage divider.

PCB5

TH1

NTC

CN11 / J36

7

8

TP0

+

-

CN1

1

2

Reasons for coolant overheated:

• Coolant fan failed

• Radiator fins clogged with dirt

• Duty cycle exceeded (ambient temperature above 40 deg C and operating

at high duty cycle)