Tweco Troubleshooting Power Supply User Manual

Page 38

38

Coolant actually flows (for 30 sec. until pump shut off due to not sensing flow):

• Flow sensor disconnected or failed, see sect. code 4-2 for description of

flow sensor operation.

• PCB5

• CCM

Damaged Coolant Tube

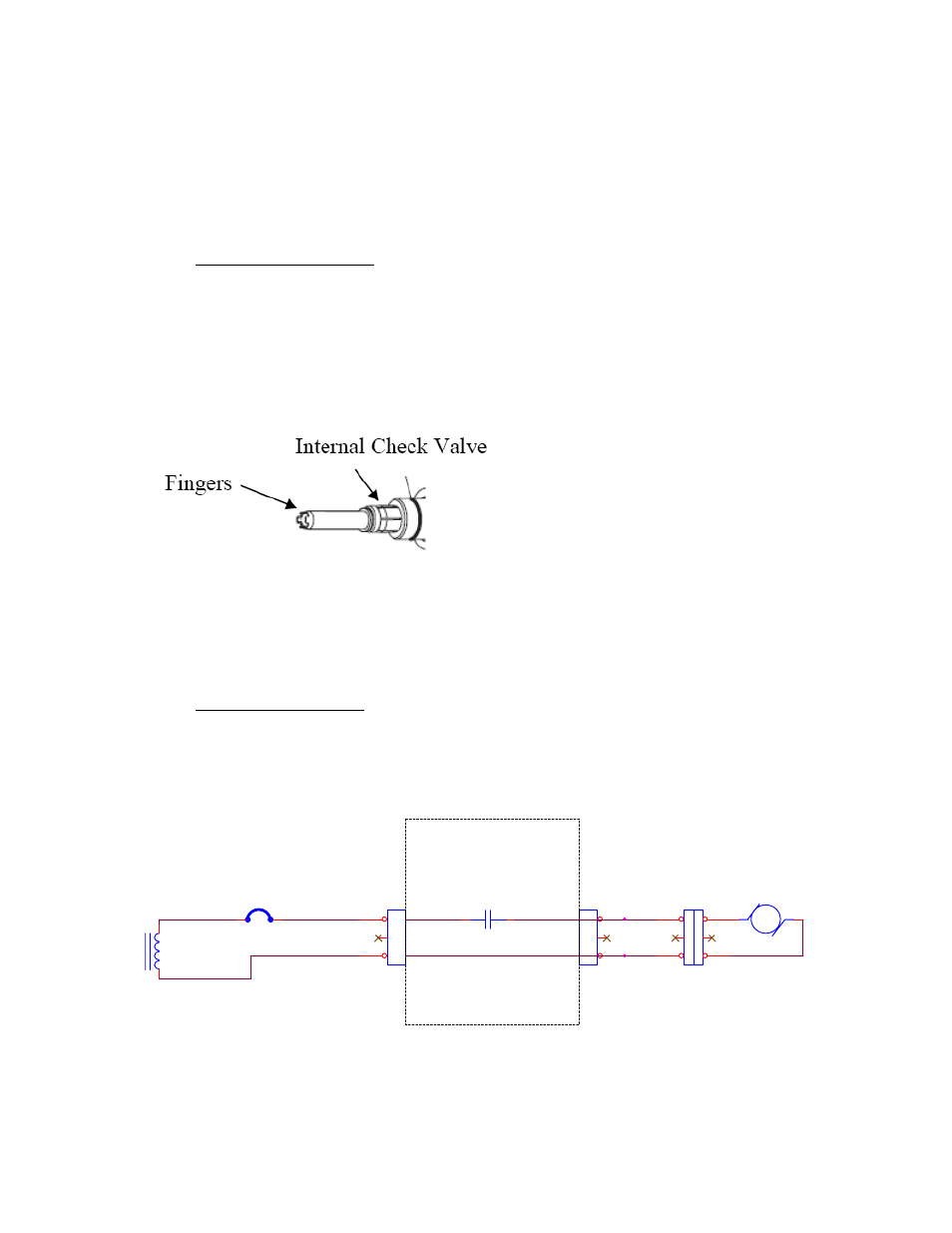

Coolant tube includes a check valve at it’s upper end. When cartridge with

consumables is not installed the spring loaded coolant tube is fully extended

closing the check valve preventing coolant from leaking out.

When consumables are in place they push the tube inward, opening the check

valve, allowing coolant to flow. The coolant tube has fingers on the end to contact

the inside of the electrode and allow coolant to flow through the openings

between the fingers.

The fingers can be bent over or broken if reasonable care is not taken when the

cartridge is not in place. If the fingers are bent or broken it shortens the tube so

the consumables may not push the tube in enough to open the check valve

resulting on no coolant flow. The coolant tube assembly may be replaced separate

from the torch head.

Power to pump motor is 200 VAC from T1 transformer through CP7 rear panel

circuit breaker to CN3-1 & 3 on relay board PCB7. Relay RY3 on PCB7 turns on

power to CN4-1&3 going to the pump motor. Power for RY3 is +15 VDC

coming from PCB5 CN8-1 to PCB7 CN8-1. A low level from PCB5 CN8-2 to

on PCB7 CN8-2 turns on RY3.

1

2

3

1

2

3

CN3

1

2

3

CN20

1

2

3

C.P7

RY4

PUMP

MOT1

'

.

T1

PCB7 WK-5628

RELAY PCB

200VAC