Quick fixed automation series torches – Tweco Quick Fixed User Manual

Page 15

6-11

Quick fixed automation series torches

SM-QFTORCH

TROuBLESHOOTING

SECTION 6:

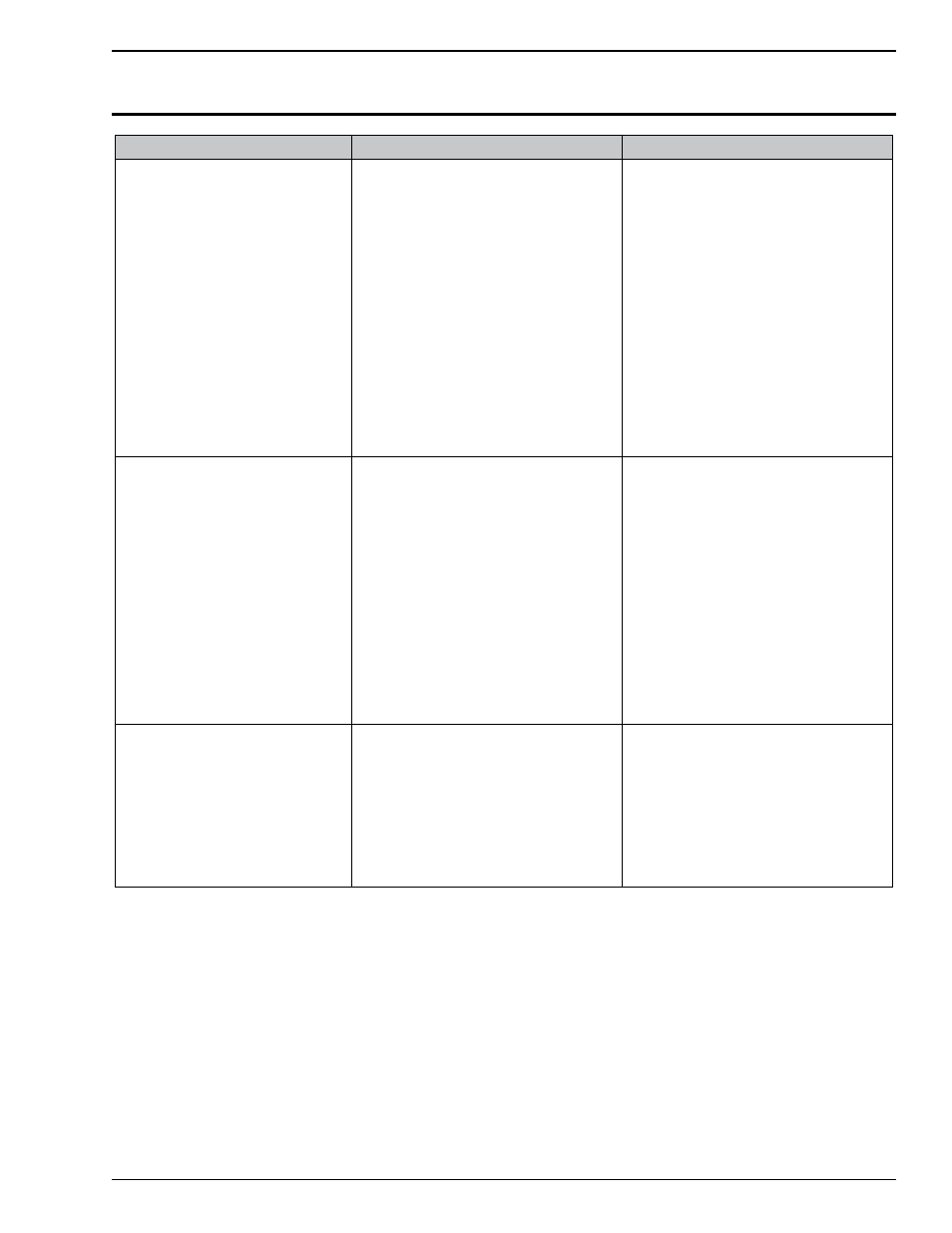

TROUBLESHOOTING

Problem

Possible Cause

Corrective Action

Wre feed nconsstent or not

smooth.

1. Loose drve rollers on feeder.

2. Drty or plugged condut

3. Condut pulled back from dffuser.

4. Sharp bends or knks n condut.

5. Machne mproperly adjusted.

6. Spatter buldup on end of contact

tp.

7. Loose contact tp or dffuser.

8. Excessvely worn contact tp.

9. Loose ground cable or ground

clamp.

1. Tghten drve rollers.

2. Replace condut.

3. Reposton condut and tghten front

screw.

4. Remove and replace condut.

5. Reset machne per machne and wre

manufacturers’ recommendatons.

6. Clean or replace contact tp.

7. Tghten contact tp and dffuser pler

tght.

8. Replace contact tp.

9. Tghten or replace as requred.

Torch and cable assembly s runnng hot. 1. L o o s e p o w e r c o n n e c t o n .

2. Loose or undersze ground cable or

ground clamp.

3. Conductor tube not tght n torch

block.

4. Loose contact tp or dffuser.

5. Operatng torch and cable assembly

above recommended amperage

ratng.

6. Power cable assembly damaged.

7. Restrcted water flow (only QFW

seres torch).

1. Inspect complete torch and cable for

loose connectons and tghten.

2. Tghten or replace as requred.

3. Tghten stanless setscrew n torch

block.

4. Tghten contact tp and dffuser.

5. Readjust machne to correct

settng for sze of torch beng used.

6. Inspect and replace accordngly.

7. Inspect water lnes for any excessve

bends.

Porous weld

1. Poor or mproper gas flo w.

2. Mosture from torch/conductor tube.

1. Drty or contamnated wre.

2. Base metal contamnaton.

1. Check gas flow out of conductor tube

nozzle. Check for leaks or restrctons

n gas hoses and connectons.

2. Check O-rngs on conductor tube and

torch block. Check the torch block for

any scarrng, gouges to the surface.

1. Change wre.

2. Replace base metal.