Warning! disconnect input power before maintaining, Quick fixed automation series torches – Tweco Quick Fixed User Manual

Page 14

5-10

Quick fixed automation series torches

SM-QFTORCH

MAINTENANCE

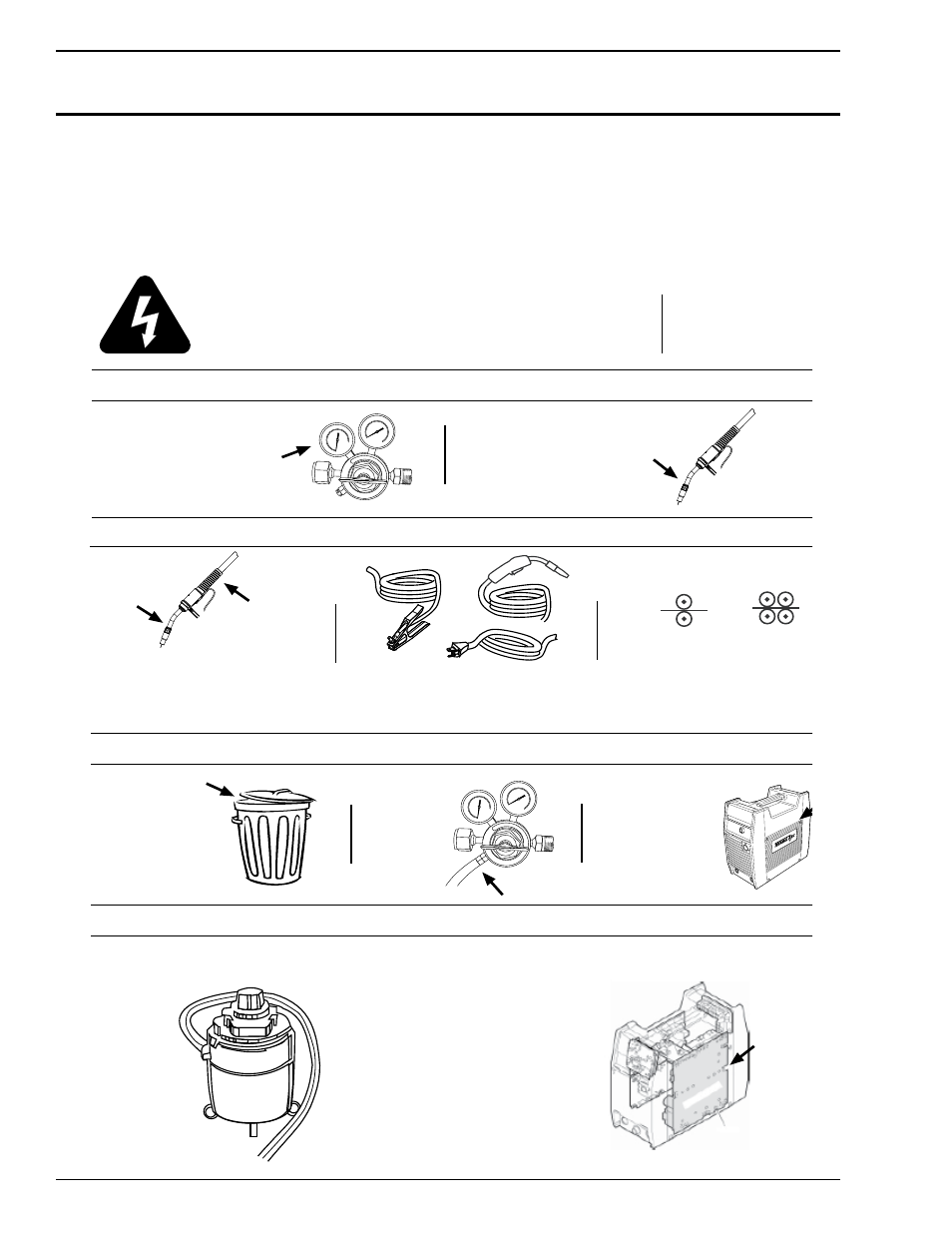

Each Use

Visual check of torch

Consumable parts

Weekly

Visually inspect the torch

body and consumables

Visually inspect the

cables and leads.

Replace as needed

3 Months

Clean

exterior

of power supply

6 Months

Replace all

broken parts

Visually check and

use a vacuum to carefully

clean the interior

Gas and

air lines

dwg-00032

Visually inspect the Wire

feed mechanisms

Warning!

Disconnect input power before maintaining.

Maintain more often

if used under severe

conditions.

Visual check of

regulator and pressure

SECTION 5:

MAINTENANCE

Contact tps and nozzles should be cleaned frequently. Spatter

buldup may cause brdgng between nozzle and tp. Ths

could cause electrcal shortng between the nozzle and work

pece as well as restrctng gas flow.

Regularly nspect the conductor tube, torch and cable

assembly for abrasons, cuts, and undue wear. Replace or

repar any parts as needed.

The torch and conductor tube assembles have o-rngs for

seals. Lubrcaton of these o-rngs should be done perodcally

and perodcal nspectons should be made to ensure that the

o-rngs do not de-grade, allowng water and/or sheldng gas

leaks to occur. When removng the conductor tube from the

torch assembly, be sure the sngle o-rng located n the bottom

of the hole remans n place.