Quick fixed automation series torches – Tweco Quick Fixed User Manual

Page 11

3-7

Quick fixed automation series torches

SM-QFTORCH

INSTALLATION AND DISASSEMBLy

16. Tghten the set screw on the Tweco

®

, Panasonc

®

, and

or Lncoln

®

rear connector plug. For Mller

®

style rear

connector plug, re-nstall the threaded connector plug

npple. Ths connecton should be wrench tght.

17. Re-nsert the factory-suppled 5/32” T-handle allen

wrench nto the hole for the “Condut Set Screw” on the

front handle cap and rotate the set screw clockwse. The

set screw should be hand tght. Refer to Fgure 3-5.

CONDUIT SET SCREW HOLE

Art # JB-00012

Fgure 3-5: Access hole for Condut Set Screw

18. Trm the condut extendng from the front of the conductor

tube assembly by followng the steps below:

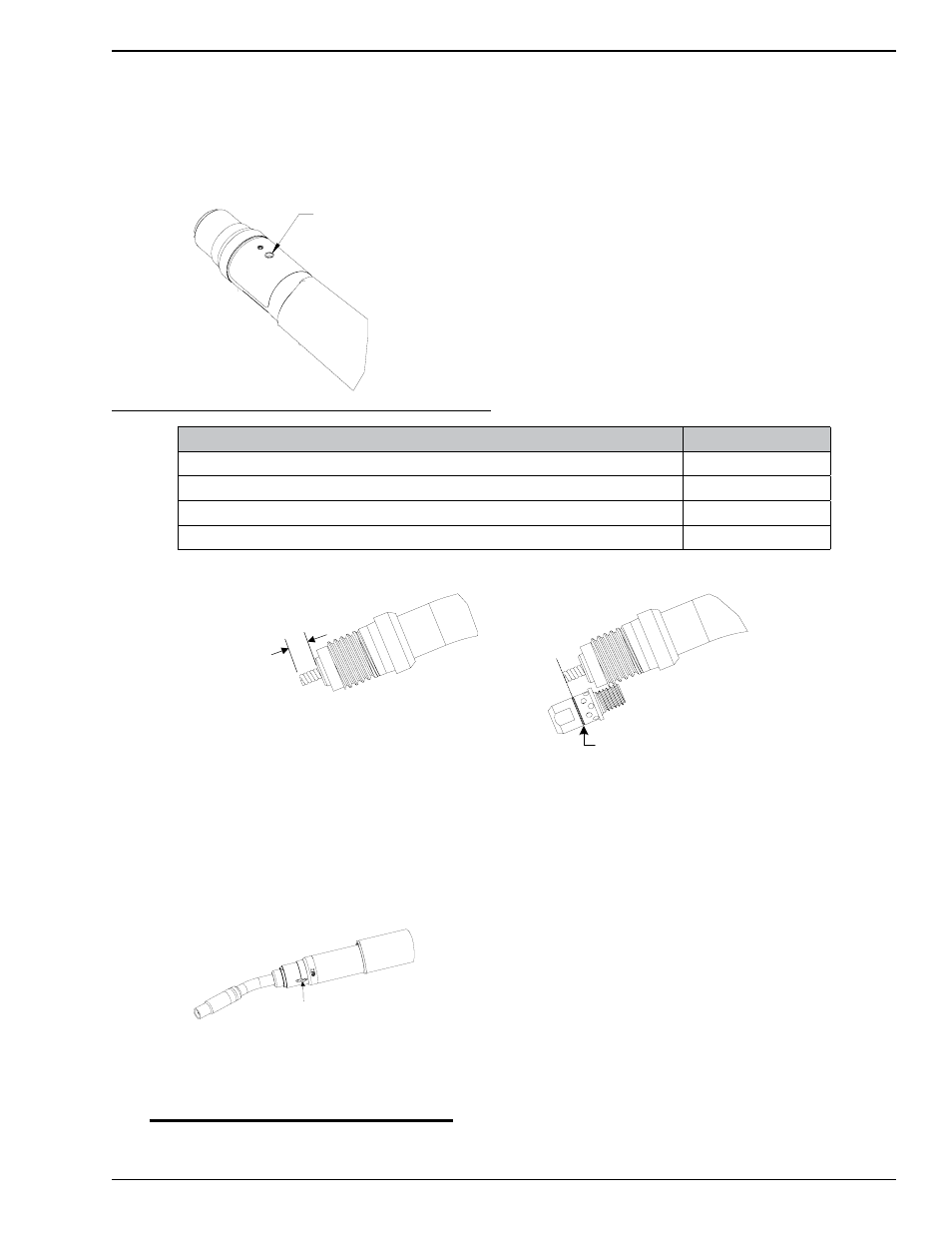

Method “A” – usng a tape measure or scale, mark and

cut the condut to the cut length noted n the

table below. Refer to Fgure 3-6 — Method

“A”.

Method “B” – The dffusers have a machned groove

around the outer dameter. Poston the

dffuser as shown n Fgure 3-6 — Method

“B” and mark and cut the condut.

Conductor Tube Assemby

Cut Length “A”

QTR66 Seres – (For use wth QRA seres torch/cable assembles)

1-5/16” (33,32mm)

QTRW63 Seres – (For use wth QRW & QRWA seres torch/cable assembles)

15/16” (23,80mm)

QTRW64 Seres – (For use wth QRW & QRWA seres torch/cable assembles)

¼” (6,35mm)

QTRW66 Seres – (For use wth QRW & QRWA seres torch/cable assembles)

5/16” (7,92mm)

Table 3-1: Conductor Tube Cut Lengths

CUT LINE

A

”

B

“

D

O

H

T

E

M

”

A

“

D

O

H

T

E

M

Art # JB-00013

19. After trmmng to length, remove any obstructons from the end of the condut radus.

20. Re-nstall the dffuser, tp, and nozzle onto the conductor tube assembly.

21. Loosen the fixture connecton and nsert the cartrdge kt of the torch and conductor tube assembly nto poston. The

keystock located on the cartrdge kt should be placed nto the matng slot on the fixture untl the sleeve bottoms aganst

the fixture plate. Re-tghten the connecton to secure the assembly n place. Refer to Fgure 3-7.

KEYSTOCK

Art # JB-00014

Fgure 3-7: Locatng Keystock

NOTE

For cable assemblies longer than 5ft. (1,52m), it

is recommended incorporating a spring-loaded

stabilizer bar/balancer to the robot work cell to

provide support to the center of the cable assembly.

This will eliminate both excessive drooping of the

cable assembly and any interference with the

fixtures and tooling in the work area.

22. Install the rear connector plug nto the feeder.

23. If the torch beng nstalled s a water-cooled QFW seres,

a water supply provdng not less than ¾ gallons/mnute

(2.84 lters/mnute) water flow, must be used durng

operaton. The water supply should be nstalled to run

when the power source s turned “on” f possble to avod

any damage to the torch and cable assembly.

Fgure 3-6: Condut Cut Length