Quick fixed automation series torches, 01 installation – Tweco Quick Fixed User Manual

Page 10

3-6

Quick fixed automation series torches

SM-QFTORCH

INSTALLATION AND DISASSEMBLy

SECTION 3:

INSTALLATION AND DISASSEMBLY

3.01 Installation

1. Remove the torch and cable assembly from the carton,

and lay the assembly n a straght and untwsted poston

on a workbench or floor.

2. Check to ensure all tems shown n Fgure 2-1 & 2-2

on Page 2-5 are located and dentfied. If any of the

component parts are mssng, please notfy the local

Tweco

®

Weldng Dstrbutor or Tweco

®

Products Customer

Care Department at 1-800-426-1888.

3. Verfy that the overall cable length s correct to fit between

the feeder - torch mount combnaton.

4. The QF seres torch and cable assembles are furnshed

wth a 1-5/8” (41,28mm) Ø mountng dameter and can

be keyed n place nto a fixture f so desred.

5. Rotate the front sleeve cover to expose the stanless steel

set screw located n the torch block assembly. Insert the

factory suppled 5/32” T-handle allen wrench nto the set

screw and rotate counterclockwse untl t stops as shown

n Fgure 3-1.

ROTATE FRONT SLEEVE COVER

TO EXPOSE SET SCREW, ROTATE

COVER TO CONCEAL SET SCREW

PRIOR TO TORCH OPERATION.

SET SCREW

(5/32" ALLEN KEY

Art # JB-00008

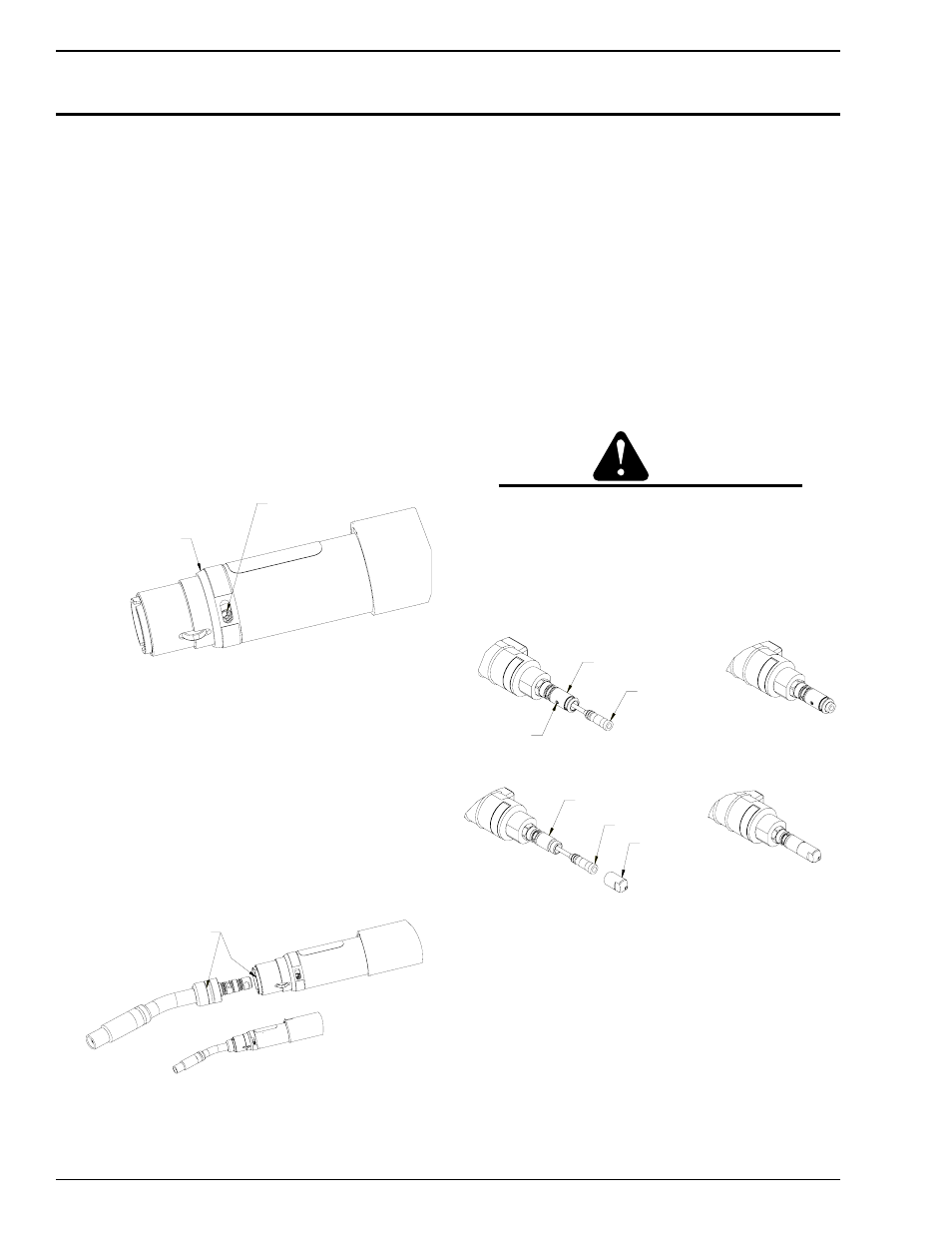

Fgure 3-1: Conductor Tube Lockng Set Screw

6. Insert the conductor tube assembly nto the torch block

assembly. The conductor tube s postvely located nto

the torch body by the use of two stanless steel algnment

pns.

7. Push the conductor tube assembly nto place untl the

stanless steel set screw can drve the back plug on the

conductor tube nto ts locked operatng poston. The

conductor tube has a machned locatng groove around

ts rear dameter. Ths groove wll be flush wth the front

housng when properly nstalled as shown n Fgure 3-

2.

WHEN CONDUCTOR TUBE IS FULLY SEATED,

GROOVE ON TUBE SHOULD LINE UP WITH

EDGE OF INSULATING SLEEVE.

Art # JB-00009

Fgure 3-2: Conductor Tube Installaton

8. Remove the gas dffuser, tp, and nozzle from the

conductor tube assembly.

9. The torch and cable assembly comes wth the Mller

®

rear

connector plug nstalled. If the feeder requres a dfferent

rear connector plug, select the correct rear connector

plug for the feeder beng used and thread the plug nto

the rear of cable assembly. Ths connecton should be

wrench tght.

10. The QF Seres torch and cable assembles are furnshed

wth R45-116 condut and the rear connector plugs to

fit ths seres of condut. If a dfferent condut and rear

connector plug s requred, refer to Page 8-18 lstng the

varous conduts that are avalable.

11. Remove the condut from the package and uncol carefully.

CAUTION

Bending or distorting the conduit can cause wire

feed problems.

12. Loosen the set screw located on the Tweco, Panasonc

®

and Lncoln

®

rear connector plug to ensure the condut wll

feed through properly. For Mller

®

style plug, remove the

threaded connector plug npple from the rear connector

plug on the torch assembly. Refer to Fgure 3-3 & 3-4.

SET SCREW

TWECO PLUG

CONDUIT ASSEMBLY

Art # JB-00010

Fgure 3-3: Condut Installaton wth Set Screw

MILLER PLUG

CONDUIT ASSEMBLY

PLUG NIPPLE

Art # JB-00011

Fgure 3-4: Condut Installaton wth Plug Npple (Mller

®

style)

13. Insert the factory-suppled 5/32” T-handle Allen wrench

through the hole on the alumnum front handle cap,

dentfied as “Condut Set Screw” on the label, and rotate

the set screw counterclockwse untl t stops rotatng.

14. Insert the exposed raw col end of the condut, factory

suppled, nto the rear connector plug. Feed the condut

through the gun and conductor tube assembly. If the

condut attempts to hang up, rotate the condut lner

counterclockwse whle gently pushng.

15. When the condut s completely through the torch and

conductor tube assembly, seat the brass condut stop

firmly aganst the connector plug.