Weldskill auto-darkening welding helmets – Tweco Cigweld WeldSkill Auto Darkening Welding Helmets User Manual

Page 11

WeldSkill Auto-Darkening Welding Helmets

10

February 29, 2012

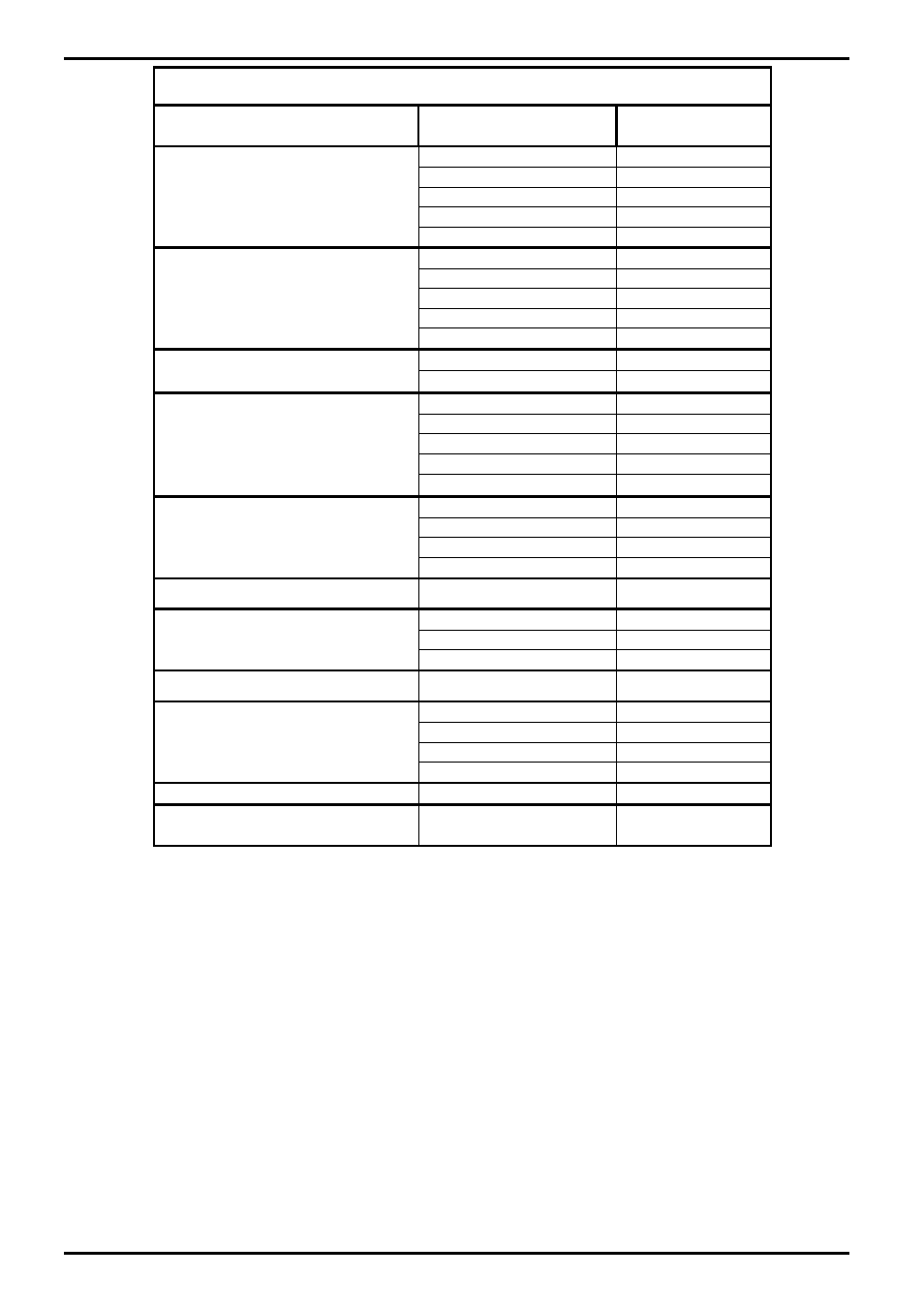

Recommended Protective Filters for Electric Welding

Description of Process

Approximate range of

Welding Current in Amps

Minimum Shade

Number of Filter(s)

Less than or equal to 100

8

100 to 200

10

200 to 300

11

300 to 400

12

Manual Metal Arc Welding - covered

electrodes (MMAW)

Greater than 400

13

Less than or equal to 150

10

150 to 250

11

250 to 300

12

300 to 400

13

Gas Metal Arc Welding (GWAW) (MIG)

other than Aluminium and Stainless Steel

Greater than 400

14

Less than or equal to 250

12

Gas Metal Arc Welding (GMAW) (MIG)

Aluminium and Stainless Steel

250 to 350

13

Less than or equal to 100

10

100 to 200

11

200 to 250

12

250 to 350

13

Gas Tungsten Arc Welding (GTAW) (TIG)

Greater than 350

14

Less than or equal to 300

11

300 to 400

12

400 to 500

13

Flux-cored Arc Welding (FCAW)

-with or without shielding gas.

Greater than 500

14

Air – Arc Gouging

Less than or equal to 400

12

50 to 100

10

100 to 400

12

Plasma-Arc Cutting

400 to 800

14

Plasma-Arc Spraying

—

15

Less than or equal to 20

8

20 to 100

10

100 to 400

12

Plasma-Arc Welding

400 to 800

14

Submerged-Arc Welding

—

2(5)

Resistance Welding

—

Safety Spectacles or

eye shield

Table 1 – Recommended Filter Lens Shade Settings.

Refer to standard AS/NZS 1338.1:1992 for comprehensive information regarding Table 1