05 error codes and remedies, Error codes and remedies -2, Transmig vaf4hd – Tweco VAF4HD Transmig User Manual

Page 62

TRANSMIG VAF4HD

SERVICE

4-2

Manual 0-5269

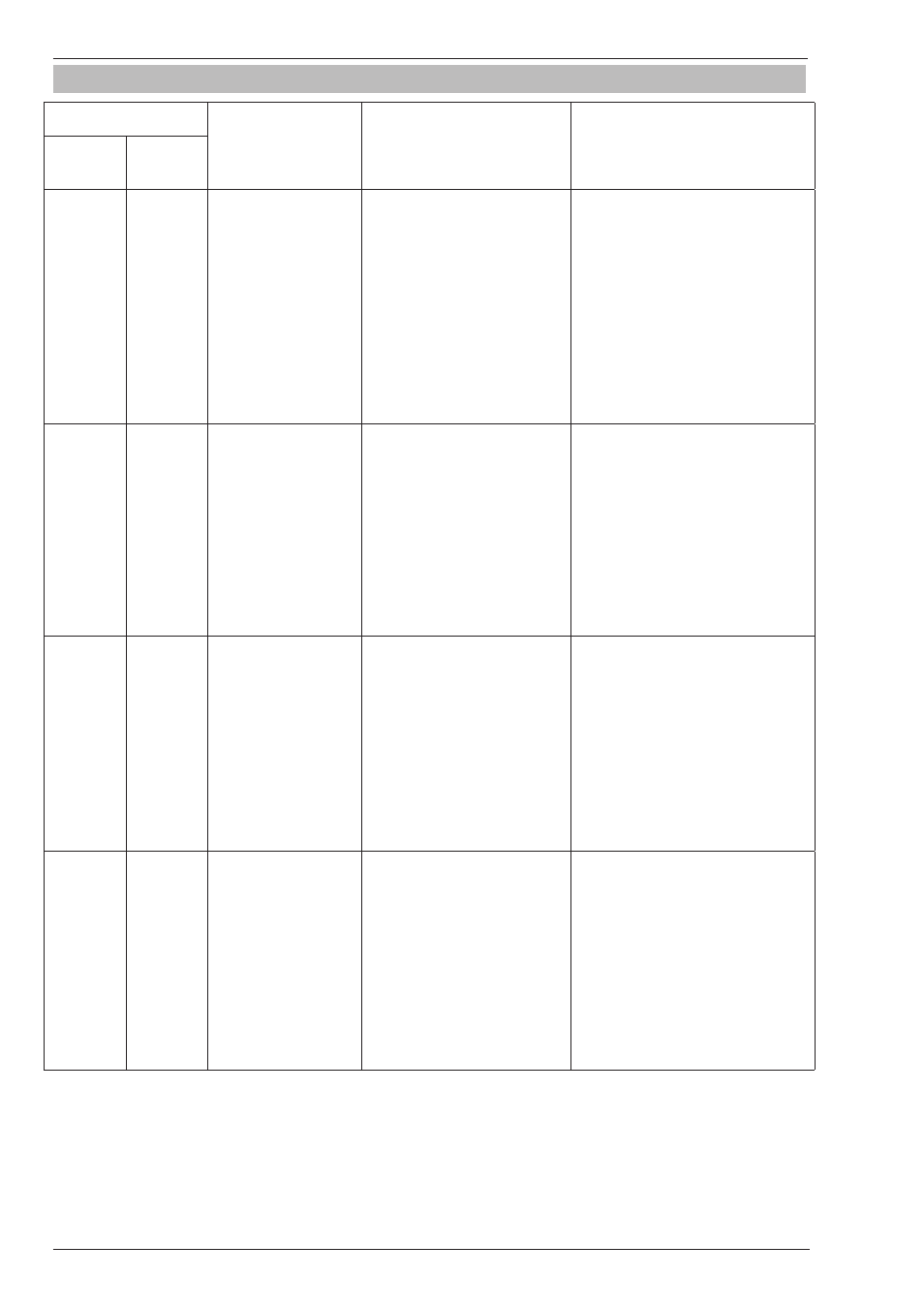

4.05 Error Codes and Remedies

Error Code

Description

Cause

Remedy

Left

Display

Right

Display

ERR

01--

This protection circuit

is activated whenever

weld current flows

in the ground fault

protective circuit.

Fault light flashes at a

rate of approximately

0.5 second ON, 0.5

second OFF.

Weld current is detected

running through the ground

fault protective circuit.

1. Look for metallic dust build

up between the wirefeed plate

assembly/motor and the Wirefeeder

frame and remove the metallic dust

build up. Turn OFF Wirefeeder then

ON again to clear ERR 01.

2. If ERR 01 appears again with

the next weld or metallic dust build

up cannot be located then contact

your Accredited CIGWELD Service

Provider to investigate the fault.

ERR

02--

Control cable

connecting Wirefeeder

and Power Source not

correctly connected.

1. 19 pin plug control plug

connection is loose at either

socket on Wirefeeder or Power

Source.

2. Control cable is damaged or

has faulty connection/s.

3. Ensure that the 19 Pin

socket is selected on the Power

Source.

1. Check control cable connections

at the Wirefeeder and Power Source

are tight.

2. If the Control Cable is damaged

then repair or replace cable.

3. Check the Power Source is set to

19 Pin socket mode.

ERR

03--

Emergency shutdown Motor current exceeds 10amps

due to seized motor or clogged

liner or filler metal wire too big

for MIG torch liner or spool

hub tension too tight, etc.

Turn OFF Wirefeeder then check

motor / feed mechanism can rotate

or replace liner or install correct size

liner for filler metal or adjust spool

hub tension.

Turn ON Wirefeeder and if ERR

03 appears again with the next

weld then contact your Accredited

CIGWELD Service Provider to

investigate the fault.

ERR

04--

Protective shutdown

Motor current exceeds 5amps

for 10 seconds due to clogged

liner or filler metal wire too big

for MIG torch liner or spool

hub tension too tight, etc.

Turn OFF Wirefeeder then check

motor / feed mechanism can rotate

or replace liner or install correct size

liner for filler metal or adjust spool

hub tension.

Turn ON Wirefeeder and if ERR

04 appears again with the next

weld then contact your Accredited

CIGWELD Service Provider to

investigate the fault.