04 power source problems, Power source problems -4, Thermal arc 201 ts service – Tweco 201 ts Thermal Arc User Manual

Page 42: Tig welding problems (continued)

THERMAL ARC 201 TS SERVICE

Service 5-4

Manual 0-5149

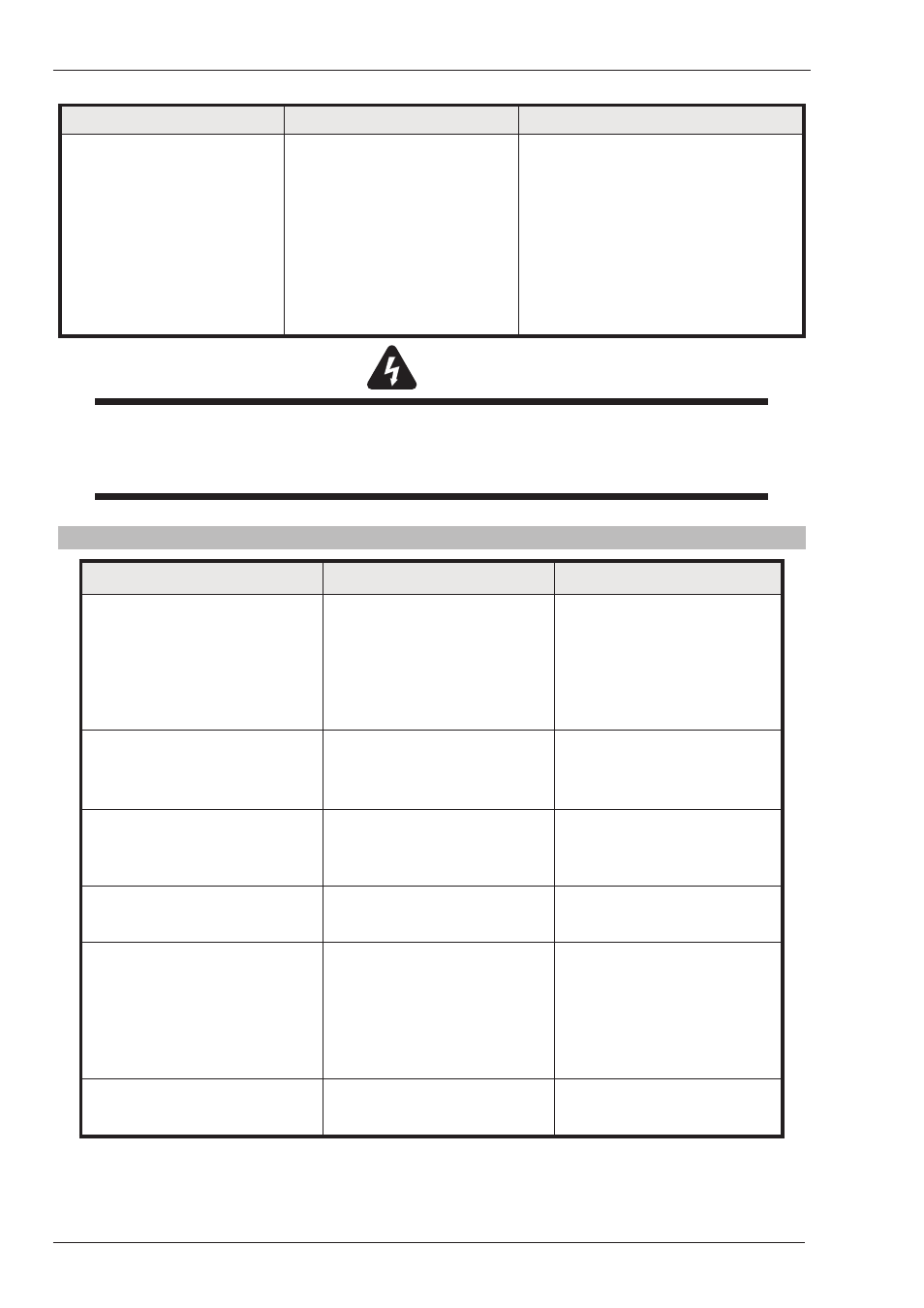

TIG Welding Problems (Continued)

Description

Possible Cause

Remedy

12. Arc start is not smooth.

A. Tungsten electrode is too

large for the welding current.

B. The wrong electrode is being

used for the welding job.

C. Gas flow rate is too high.

D. Incorrect shield gas is being

used.

E. Poor work clamp connection

to work piece.

A. Refer to section Tungsten Electrode

Current Ranges for the correct size.

B. Refer to section Tungsten Electrode

Types for the correct electrode type.

C. Select the correct flow rate for the

welding job.

D. Use 100% argon for TIG welding.

E. Improve connection to work piece.

WARNING

There are extremely dangerous voltages and power levels present inside this product. Do not attempt

to repair unless you are an Accredited Thermal Arc Service Agent and you have had training in power

measurements and troubleshooting techniques. If major complex subassemblies are faulty, then the

Welding Power Source must be returned to an Accredited Thermal Arc Service Agent for repair.

5.04 Power Source Problems

Description

Possible Cause

Remedy

1. The welding arc cannot be

established.

A. The Primary supply voltage

has not been switched ON.

B. The Welding Power Source

switch is switched OFF.

C. Loose connections internally.

A. Switch ON the Primary

supply voltage.

B. Switch ON the Welding

Power Source.

C. Have an Accredited Thermal

Arc Service Provider repair

the connection.

2. The welding arc cannot be

established when the Warning

Indicator lights up continuously

The machines duty cycle has

been exceeded

Wait for the Warning Indicator

to extinguish before resuming

welding

3. Maximum output welding

current cannot be achieved

with nominal Mains supply

voltage.

Defective control circuit

Have an Accredited Thermal Arc

Service Provider inspect then

repair the welder.

4. Welding current reduces when

welding.

Poor work lead connection to the

work piece.

Ensure that the work lead has a

positive electrical connection to

the work piece.

5. Circuit breaker (or fuse) trips

during welding.

The circuit breaker (or fuse) is

under size.

The recommended circuit

breaker (or fuse) size is 32 amp.

An individual branch circuit

capable of carrying 32 amperes

and protected by fuses or circuit

breaker is recommended for this

application.

6. The welding arc cannot

be established when Fault

Indicator is flashing.

The input current to the main

transformer has been exceeded.

Have an Accredited Thermal Arc

Service Provider inspect then

repair the welder.