05 gtaw electrode polarity, 06 guide for selecting filler wire, 07 tungsten electrode current ranges – Tweco 201 ts Thermal Arc User Manual

Page 30: 08 shielding gas selection, Gtaw electrode polarity -4, Guide for selecting filler wire -4, Tungsten electrode current ranges -4, Shielding gas selection -4, Thermal arc 201 ts operation

THERMAL ARC 201 TS OPERATION

Operation 4-4

Manual 0-5149

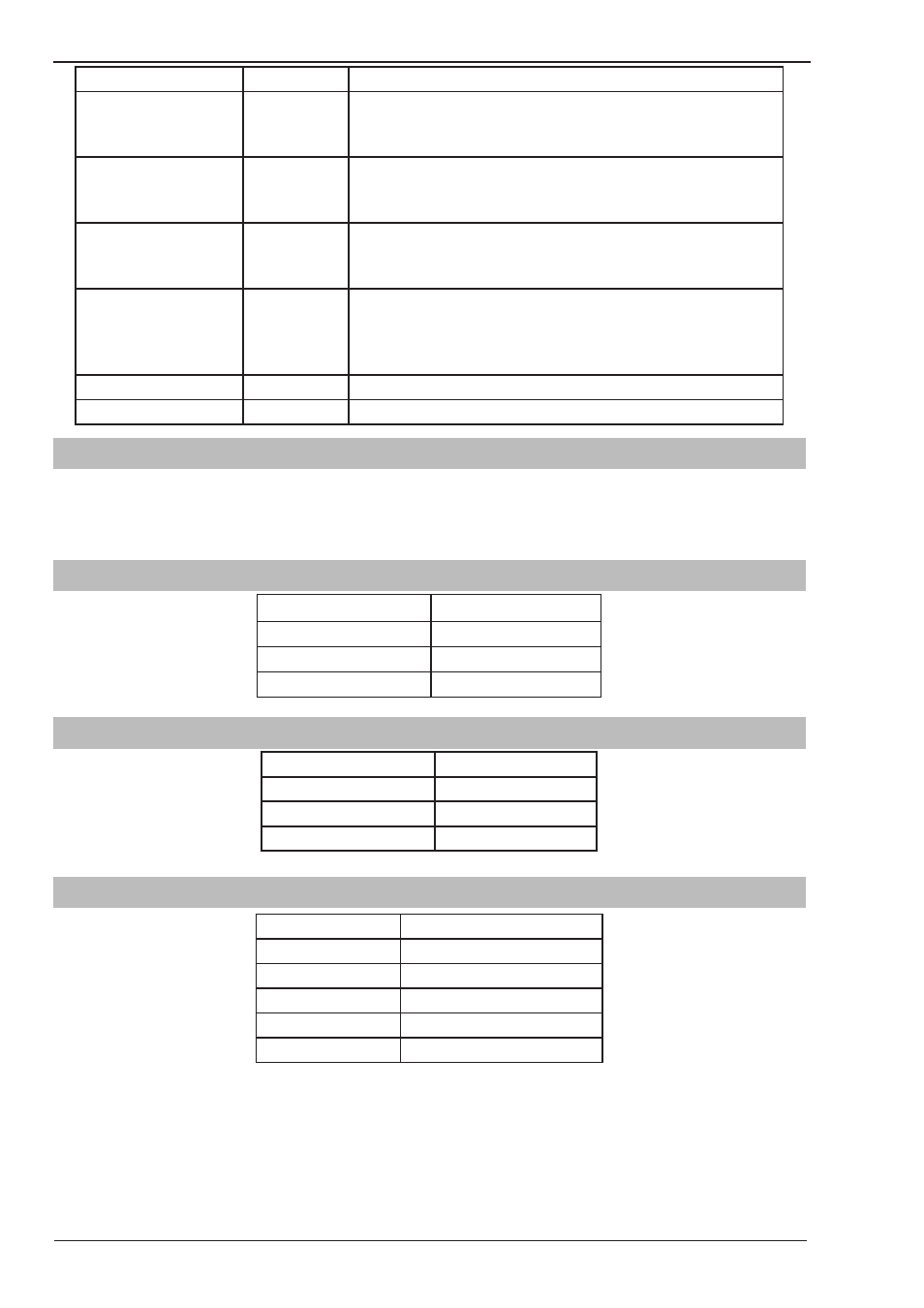

Metal Being Joined

Electrode

Comments

Mild Steel

E6011

This electrode is used for all-position welding or for welding on

rusty, dirty, less-than-new metal. It has a deep, penetrating arc

and is often the first choice for repair or maintenance work.

Mild Steel

E6013

This all-position, electrode is used for welding clean, new sheet

metal. Its soft arc has minimal spatter, moderate penetration and

an easy-to-clean slag.

Mild Steel

E7014

All positional, ease to use electrode for use on thicker steel than

E6013. Especially suitable sheet metal lap joints and fillet welds,

general purpose plate welding.

Mild Steel

E7018

A low-hydrogen, all-position electrode used when quality is an

issue or for hard-to-weld metals. It has the capability of producing

more uniform weld metal, which has better impact properties at

low temperatures.

Cast Iron

Eni-Cl

Suitable for joining all cast irons except white cast iron.

Stainless Steel

E318L-16

High corrosion resistances. Ideal for dairy work etc.

4.05 GTAW Electrode Polarity

Connect the TIG torch to the "-" Negative Output Terminal and the work lead to the "+" Positive Output Terminal for

direct current straight polarity. Direct current straight polarity is the most widely used polarity for DC TIG welding.

It allows limited wear of the electrode since 70% of the heat is concentrated at the work piece.

4.06 Guide for Selecting Filler Wire

Filler Wire Diameter

DC Current (Amps)

1.6mm (1/16")

20 - 90

2.4mm (3/32")

65 - 115

3.2mm (1/8")

100 - 165

4.07 Tungsten Electrode Current Ranges

Electrode Diameter

DC Current

1.0mm (.040”)

25 - 85

1.6mm (1/16”)

50 - 160

2.4mm (3/32”)

135 - 235

4.08 Shielding Gas Selection

Alloy

Shielding Gas

Carbon Steel

Welding Argon

Stainless Steel

Welding Argon

Nickel Alloy

Welding Argon

Copper

Welding Argon

Titanium

Welding Argon