20 distortion, 21 the cause of distortion, 20 distortion -11 4.21 – Tweco 201 ts Thermal Arc User Manual

Page 37: The cause of distortion -11, Operation thermal arc 201 ts

OPERATION THERMAL ARC 201 TS

Manual 0-5149

4-11 Operation

B. Expansion and Contraction of Parent Metal in the

Fusion Zone:

While welding is proceeding, a relatively small volume

of the adjacent plate material is heated to a very high

temperature and attempts to expand in all directions.

It is able to do his freely at right angles to the surface

of the plate (i.e., “through the weld”), but when it at-

tempts to expand “across the weld” or “along the weld”,

it meets considerable resistance, and to fulfill the desire

for continued expansion, it has to deform plastically, that

is, the metal adjacent to the weld is at a high tempera-

ture and hence rather soft, and, by expanding, pushes

against the cooler, harder metal further away, and tends

to bulge (or is “upset”). When the weld area begins to

cool, the “upset” metal attempts to contract as much as

it expanded, but, because it has been “upset”, it does

not resume its former shape, and the contraction of

the new shape exerts a strong pull on adjacent metal.

Several things can then happen.

The metal in the weld area is stretched (plastic defor-

mation), the job may be pulled out of shape by the

powerful contraction stresses (distortion), or the weld

may crack, in any case, there will remain “locked-up”

stresses in the job. Figures 4-20 and 4- 21 illustrate

how distortion is created.

Art # A-07705_AB

Hot

Hot

Weld

Upsetting

Expansion with

compression

Cool

Figure 4-21: Parent metal expansion

Art # A-07706_AB

Weld

Permanent Upset

Contraction

with tension

Figure 4-22: Parent metal contraction

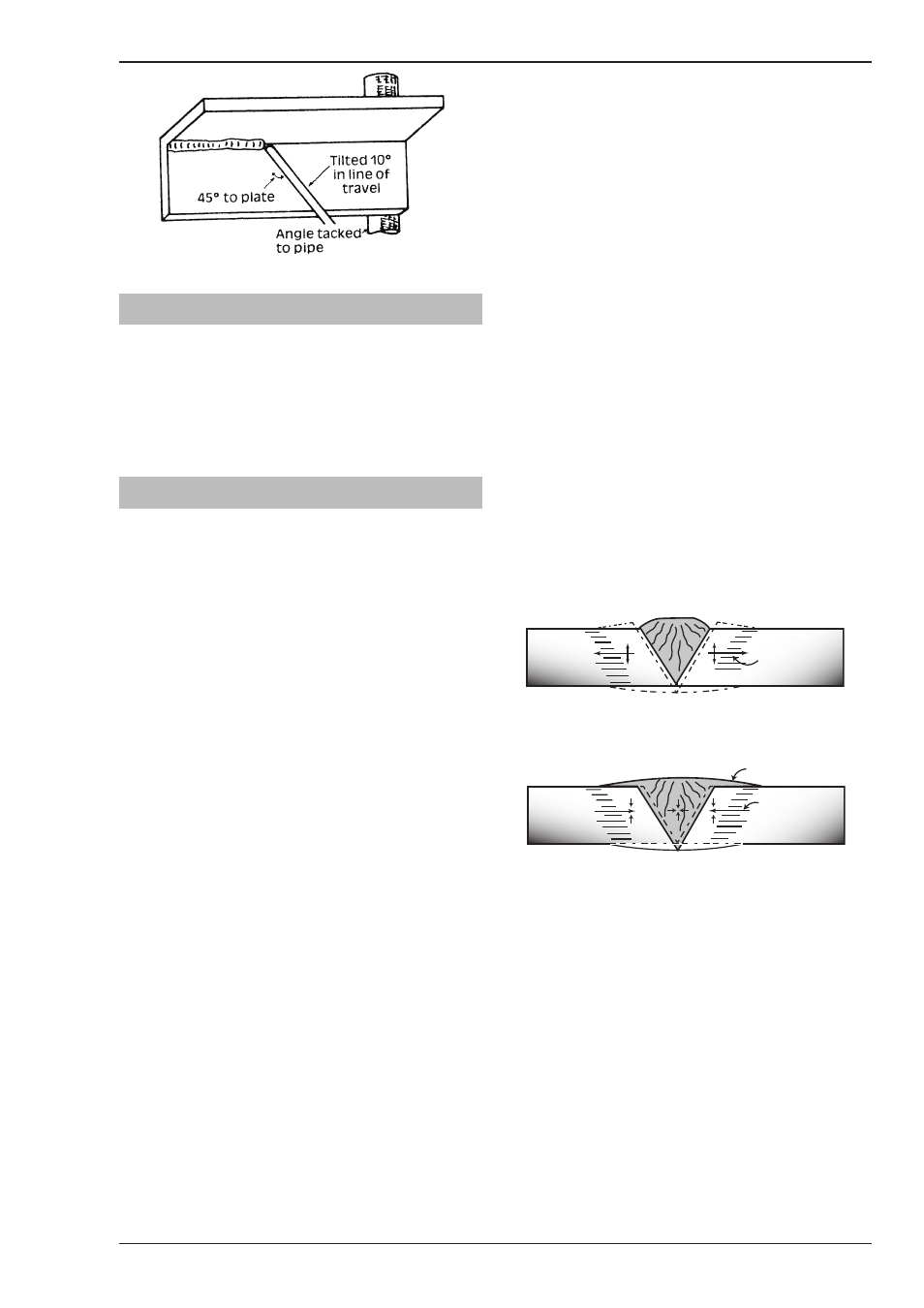

Art # A-07704

Figure 4-20: Overhead fillet weld

4.20 Distortion

Distortion in some degree is present in all forms of

welding. In many cases it is so small that it is barely

perceptible, but in other cases allowance has to be made

before welding commences for the distortion that will

subsequently occur. The study of distortion is so com-

plex that only a brief outline can be attempted hear.

4.21 The Cause of Distortion

Distortion is cause by:

A. Contraction of Weld Metal:

Molten steel shrinks approximately 11 per cent in vol-

ume on cooling to room temperature. This means that

a cube of molten metal would contract approximately

2.2 per cent in each of its three dimensions. In a welded

joint, the metal becomes attached to the side of the joint

and cannot contract freely. Therefore, cooling causes

the weld metal to flow plastically, that is, the weld itself

has to stretch if it is to overcome the effect of shrinking

volume and still be attached to the edge of the joint. If

the restraint is very great, as, for example, in a heavy

section of plate, the weld metal may crack. Even in

cases where the weld metal does not crack, there will

still remain stresses “locked-up” in the structure. If the

joint material is relatively weak, for example, a butt joint

in 2.0mm (5/64") sheet, the contracting weld metal may

cause the sheet to become distorted.