02 welding current control explanation, 03 stick (mma) electrode polarity, 04 effects of stick welding various materials – Tweco 201 ts Thermal Arc User Manual

Page 29: Welding current control explanation -3, Stick (mma) electrode polarity -3, Effects of stick welding various materials -3, Operation thermal arc 201 ts

OPERATION THERMAL ARC 201 TS

Manual 0-5149

4-3 Operation

J. ON/OFF Switch (located on rear panel not shown)

This switch controls the Mains Supply Voltage to the

Power Source.

4.02 Welding Current Control

Explanation

32 Amp Outlet

The mains power 32 Amp circuit breaker or fuse should

not trip at this Weld Current value when STICK welding.

The environmental conditions that may cause the mains

power 32 Amp circuit breaker or fuse to trip are:

a) High ambient temperature

b) Worn parts in circuit breaker

c) Using an extension cable

d) Low line mains power voltage

Output Scale for 110V

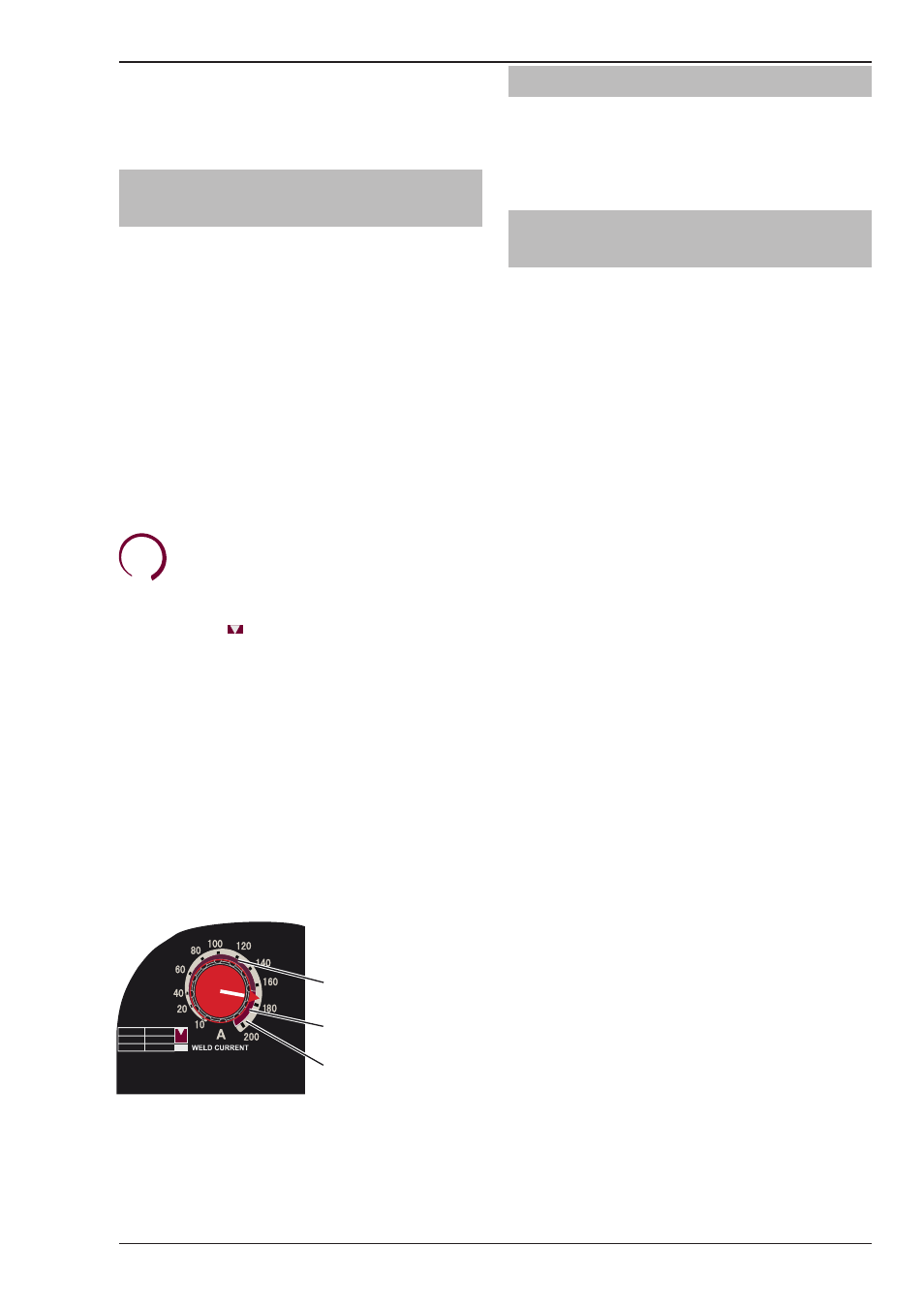

The inside number scale identifies the available

output weld current for STICK or LIFT TIG weld modes.

STICK Mode:

Identifies the STICK weld point for

32 Amp outlet.

Exceeding these points will cause nui-

sance tripping of the circuit breaker or

fuse.

Nuisance tripping should not occur on a 16 Amp outlet.

Output Scale for 230V

The outside number scale identifies the available out-

put weld current for STICK or LIFT TIG/HF TIG weld

modes.

Nuisance tripping should not occur on a 32A 230V outlet

for both STICK & LIFT TIG/HF TIG Modes.

Art # A-10147

32 Amp Outlet

Output Scale for 110V

Output Scale for 230V

32A OUTLET

STICK

TIG

230V

110V

TIG/STICK

32A OUTLET

16A OUTLET

Figure 4-2: Current Control

4.03 STICK (MMA) Electrode Polarity

Stick electrodes are generally connected to the "+" Posi-

tive Output Terminal and the work lead to the "−" Negative

Output Terminal but if in doubt consult the electrode

manufacturers literature for further information.

4.04 Effects of Stick Welding Various

Materials

High Tensile and Alloy Steels

The two most prominent effects of welding these steels

are the formation of a hardened zone in the weld area,

and, if suitable precautions are not taken, the occurrence

in this zone of under-bead cracks. Hardened zone and

under-bead cracks in the weld area may be reduced by

using the correct electrodes, preheating, using higher

current settings, using larger electrodes sizes, short

runs for larger electrode deposits or tempering in a

furnace.

Manganese Steels

The effect on manganese steel of slow cooling from

high temperatures is to embrittle it. For this reason it

is absolutely essential to keep manganese steel cool

during welding by quenching after each weld or skip

welding to distribute the heat.

Cast Iron

Most types of cast iron, except white iron, are weldable.

White iron, because of its extreme brittleness, gener-

ally cracks when attempts are made to weld it. Trouble

may also be experienced when welding white-heart

malleable, due to the porosity caused by gas held in

this type of iron.

Copper and Alloys

The most important factor is the high rate of heat

conductivity of copper, making pre-heating of heavy

sections necessary to give proper fusion of weld and

base metal.

Types of Electrodes

Arc Welding electrodes are classified into a number of

groups depending on their applications. There are a

great number of electrodes used for specialized indus-

trial purposes which are not of particular interest for ev-

eryday general work. These include some low hydrogen

types for high tensile steel, cellulose types for welding

large diameter pipes, etc The range of electrodes dealt

with in this publication will cover the vast majority of

applications likely to be encountered; are all easy to use.