Fabricator 141i – Tweco 141i Fabricator User Manual

Page 71

Fabricator 141i

Manual 0-5145

4-11

BASIC WELDING GUIDE

Copper and Alloys

The most important factor is the high rate of heat conductivity of copper, making pre-heating of heavy sections

necessary to give proper fusion of weld and base metal.

Types of Electrodes

Arc Welding electrodes are classified into a number of groups depending on their applications. There are a great

number of electrodes used for specialized industrial purposes which are not of particular interest for everyday

general work. These include some low hydrogen types for high tensile steel, cellulose types for welding large

diameter pipes, etc The range of electrodes dealt with in this publication will cover the vast majority of applications

likely to be encountered; are all easy to use.

Arc Welding Practice

The techniques used for arc welding are almost identical regardless of what types of metals are being joined.

Naturally enough, different types of electrodes would be used for different metals as described in the preceding

section.

Welding Position

The electrodes dealt with in this publication can be used in most positions, i.e. they are suitable for welding in

flat, horizontal, vertical and overhead positions. Numerous applications call for welds to be made in positions

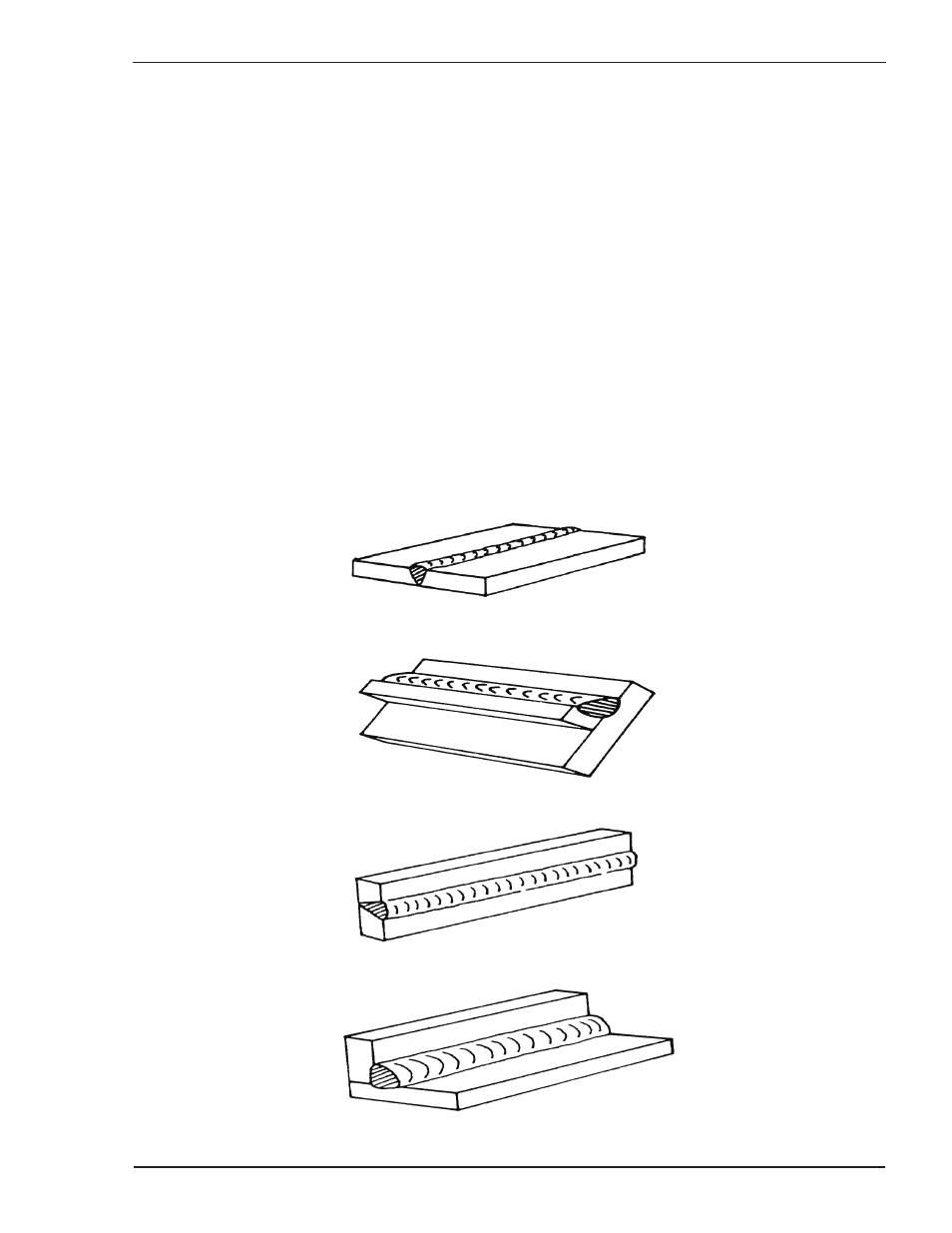

intermediate between these. Some of the common types of welds are shown in Figures 4-11 through 4-18.

Art # A-07687

Figure 4-11: Flat Position, Down Hand Butt Weld

Art # A-07688

Figure 4-12: Flat Position, Gravity Fillet Weld

Art # A-07689

Figure 4-13: Horizontal Position, Butt Weld

Art # A-07690

Figure 4-14: Horizontal-Vertical (HV) Position