Fabricator 141i – Tweco 141i Fabricator User Manual

Page 35

Fabricator 141i

Manual 0-51

45

3-5

INSTALLATION, OPERATION AND SETUP

!

WARNING

Use the flowmeter/ regulator for the gas and

pressure for which it is designed. NEVER

alter a flowmeter/ regulator for use with

any other gas.

NOTE

Flowmeters/ Regulators supplied with

5/8" -18 standard inert gas connections.

Flowmeters/ Regulators purchased with

open 1/8”, 1/4”, 3/8”, or 1/2” NPT ports

must be assembled to their intended system.

1. Note the maximum inlet pressure stamped

on the flowmeter/ regulator. DO NOT attach

the flowmeter/ regulator to a system that has

a higher pressure than the maximum rated

pressure stamped on the flowmeter/ regulator.

2. The flowmeter/ regulator body will be stamped

“IN” or “HP” at the inlet port. Attach the inlet

port to the system supply pressure connection.

3. If gauges are to be attached to the flowmeter/

regulator and the flowmeter/ regulator is

stamped and listed by a third party (i.e. “UL”

or “ETL”). The following requirements must be

met:

a) Inlet gauges over 1000 PSIG (6.87 mPa)

shall conform with the requirements of UL

404, “Indicating Pressure Gauges for Com-

pressed Gas Service.”

b) Low pressure gauges must be UL recognized

for the class of flowmeter/ regulator they are

being used on according to UL252A.

!

WARNING

DO NOT use a flowmeter/ regulator that

delivers pressure exceeding the pressure

rating of the downstream equipment

unless pro visions are made to prevent

over-pressurization (i.e. system relief

valve). Make sure the pressure rating of

the down stream equipment is compatible

with the maximum delivery pressure of the

flowmeter/ regulator.

4. Be sure that the flowmeter/ regulator has the

correct pressure rating and gas service for the

cylinder used.

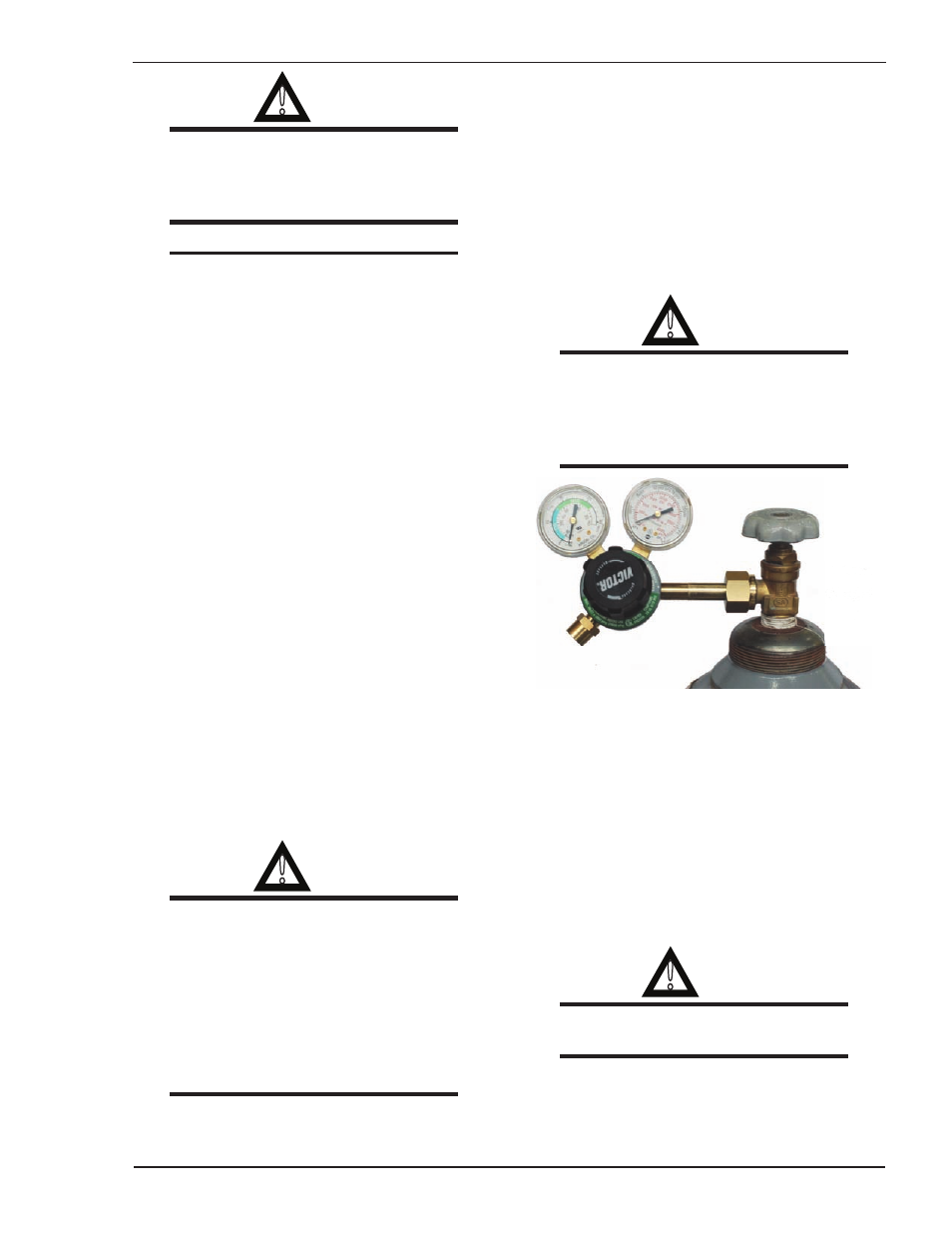

5. Carefully inspect the flowmeter/ regulator for

damaged threads, dirt, dust, grease, oil, or

other flammable substances. Remove dust and

dirt with a clean cloth. Be sure the inlet swivel

filter is clean and in place. Attach the flowmeter/

regulator (Figure 3-2) to the cylinder valve.

Tighten securely with a wrench.

!

WARNING

DO NOT attach or use the flowmeter/

regulator if oil, grease, flamma ble substances

or damage is present! Have a qualified repair

technician clean the flowmeter/ regulator or

repair any damage.

Art # A-09845

Figure 3-2: Flowmeter/ Regulator to Cylinder

Valve

6. Before opening the cylinder valve, turn

the flowmeter/ regulator adjusting screw

counterclockwise until there is no pressure on

the adjusting spring and the screw turns freely.

7. Relief Valve (where provided): The relief valve is

designed to protect the low pressure side of the

flowmeter/ regulator from high pres sures. Relief

valves are not intended to protect down stream

equipment from high pressures.

!

WARNING

DO NOT tamper with the relief valve or

remove it from the flowmeter/ regulator.