06 victor flowmeter/ regulator, Victor flowmeter/ regulator -4, Fabricator 141i – Tweco 141i Fabricator User Manual

Page 34

Fabricator 141i

INSTALLATION, OPERATION AND SETUP

3-4

Manual 0-5145

7. The time of day that welding or other activities

are to be carried out.

8. The compatibility of other equipment in the

environment: the user shall ensure that other

equipment being used in the environment

is compatible: this may require additional

protection measures.

The size of the surrounding area to be considered

will depend on the structure of the building and other

activities that are taking place. The surrounding area

may extend beyond the boundaries of the premises.

C. Methods of Reducing Electromagnetic Emissions

1. Electricity Supply

Welding equipment should be connected to the

Electricity Supply according to the manufacturer’s

recommendations. If interference occurs, it may

be necessary to take additional precautions

such as filtering of the Electricity Supply.

Consideration should be given to shielding the

supply cable of permanently installed welding

equipment in metallic conduit or equivalent.

Shielding should be electrically continuous

throughout it’s length. The shielding should be

connected to the Welding Power Source so that

good electrical contact is maintained between

the conduit and the Welding Power Source

enclosure.

2. Maintenance of Welding Equipment

The welding equipment should be routinely

maintained according to the manufacturer’s

recommendations. All access and service doors

and covers should be closed and properly

fastened when the welding equipment is in

operation. The welding equipment should not be

modified in any way except for those changes

and adjustments covered in the manufacturer’s

instructions. In particular, the spark gaps of

arc striking and stabilizing devices should

be adjusted and maintained according to the

manufacturer’s recommendations.

3. Welding Cables

The welding cables should be kept as short

as possible and should be positioned close

together, running at or close to the floor level.

4. Equipotential Bonding

Bonding of all metallic components in the

welding installation and adjacent to it should

be considered. However. Metallic components

bonded to the work piece will increase the

risk that the operator could receive a shock

by touching the metallic components and the

electrode at the same time. The operator should

be insulated from all such bonded metallic

components.

5. Earthing of the Workpiece

Where the workpiece is not bonded to earth

for electrical safety, nor connected to earth

because of it’s size and position, e.g. ship’s hull

or building steelwork, a connection bonding

the workpiece to earth may reduce emissions

in some, but not all instances. Care should be

taken to prevent the earthing of the workpiece

increasing the risk of injury to users, or damage

to other electrical equipment. Where necessary,

the connection of the workpiece to earth should

be made by direct connection to the workpiece,

but in some countries where direct connection is

not permitted, the bonding should be achieved

by suitable capacitance, selected according to

national regulations.

6. Screening and Shielding

Selective screening and shielding of other cables

and equipment in the surrounding area may

alleviate problems of interference. Screening the

entire welding installation may be considered for

special applications.

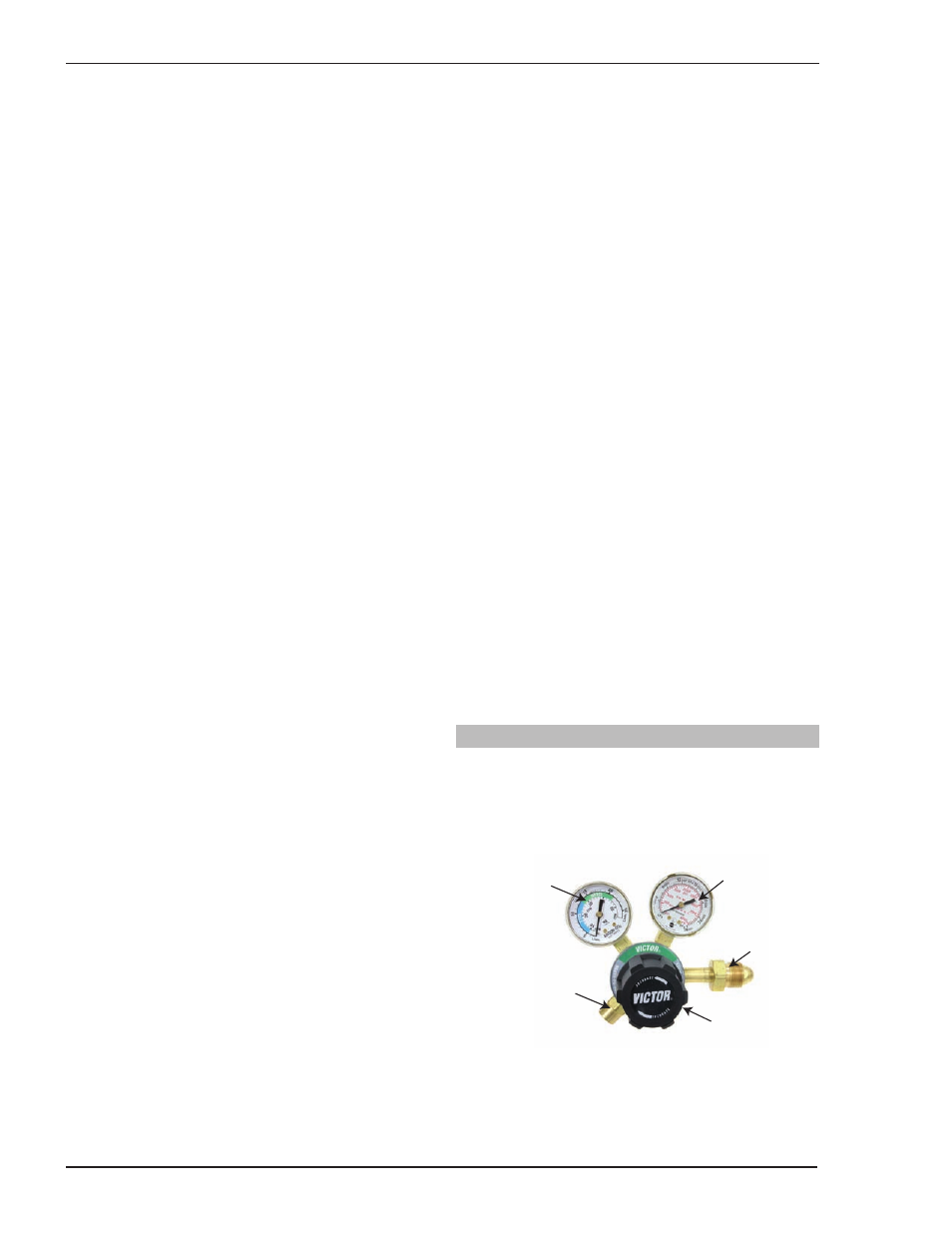

3.06 Victor Flowmeter/ Regulator

Flowmeter/ Regulator (Figure 3-1) attached to the

cylinder valve reduces high cylinder pressures to

suitable low working pressures for welding, cutting,

and other applications.

LOW PRESSURE

GAUGE (DELIVERY)

HIGH PRESSURE

GAUGE (SUPPLY)

INLET

CONNECTION

OUTLET

CONNECTION

PRESSURE

ADJUSTING

SCREW

A-09414_AB

Figure 3-1: Victor CS Flowmeter/ Regulator