03 stick (smaw) basic welding technique, 04 effects of stick welding various materials, Stick (smaw) basic welding technique -10 – Tweco 141i Fabricator User Manual

Page 70: Effects of stick welding various materials -10, Fabricator 141i

Fabricator 141i

BASIC WELDING GUIDE

4-10

Manual 0-5145

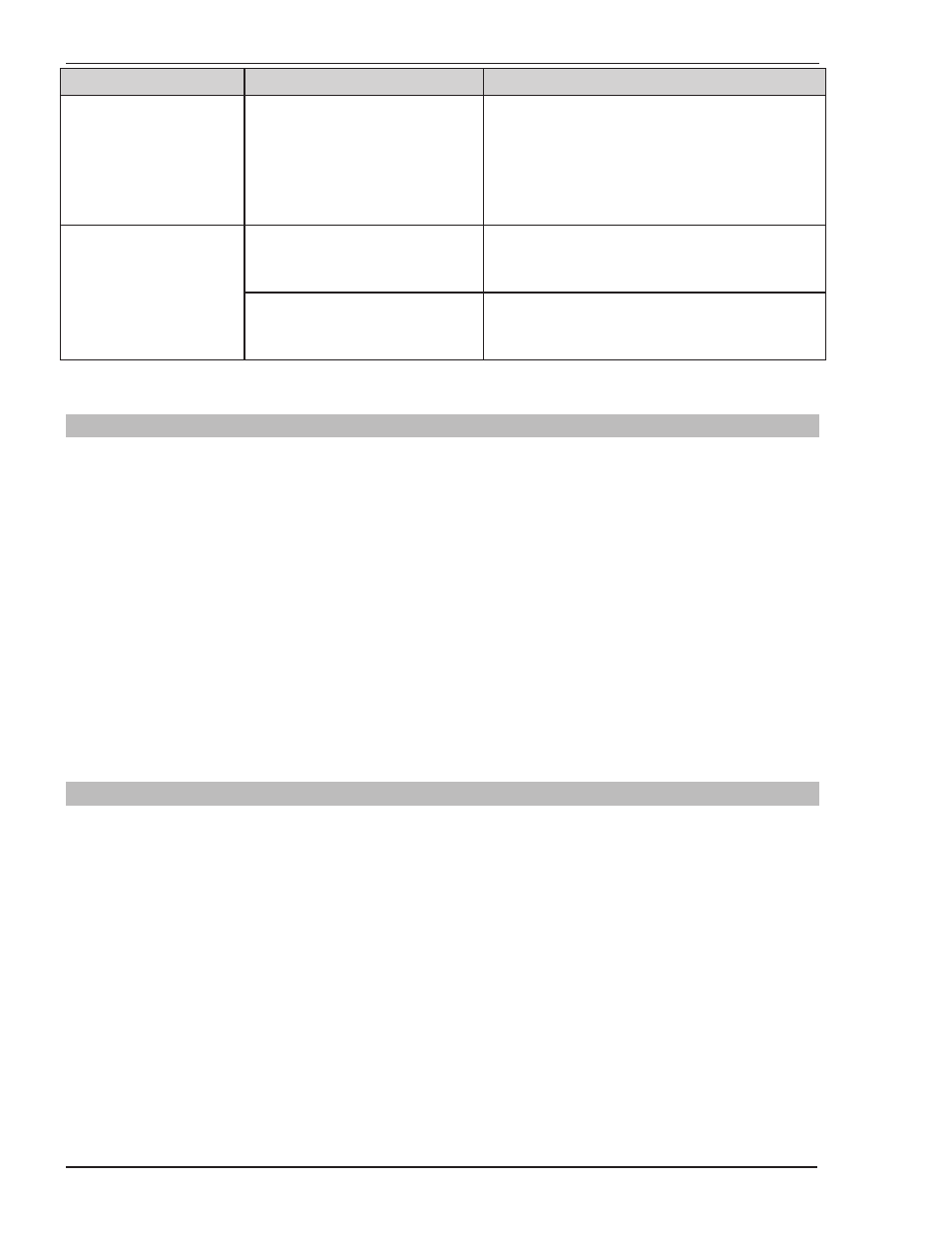

FAULT

CAUSE

REMEDY

8 Arc does not have a

crisp sound that short

arc exhibits when the

wirefeed speed and

voltage are adjusted

correctly.

The MIG Gun has been con-

nected to the wrong voltage

polarity on the front panel

Connect the MIG Gun to the positive (+)

welding terminal for solid wires and gas

shielded flux cored wires. Refer to the

electrode wire manufacturer for the correct

polarity.

9 Poor weld result from

setup chart parameters

A Incorrect welder setup, polar-

ity, shielding gas, wire type and

size

A Check to make sure that the welder is set up

correctly; also check polarity, shielding gas,

wire type and size.

B Contact tip has arc marks in the

bore causing excessive drag on

the wire

B Replace the contact tip with only a Genuine

Velocity contact tip.

Table 4-4: MIG Welding Problems

4.03 Stick (SMAW) Basic Welding Technique

Size of Electrode

The electrode size is determined by the thickness of metals being joined and can also be governed by the type

of welding machine available. Small welding machines will only provide sufficient current (amperage) to run the

smaller size electrodes.

For thin sections, it is necessary to use smaller electrodes otherwise the arc may burn holes through the job. A

little practice will soon establish the most suitable electrode for a given application.

Storage of Electrodes

Always store electrodes in a dry place and in their original containers.

Electrode Polarity

Electrodes are generally connected to the ELECTRODE HOLDER with the Electrode Holder connected positive

polarity. The WORK LEAD is connected negative polarity and is connected to the work piece. If in doubt consult

the electrode data sheet or your nearest Accredited Tweco Distributor.

4.04 Effects of Stick Welding Various Materials

High Tensile and Alloy Steels

The two most prominent effects of welding these steels are the formation of a hardened zone in the weld area, and,

if suitable precautions are not taken, the occurrence in this zone of under-bead cracks. Hardened zone and under-

bead cracks in the weld area may be reduced by using the correct electrodes, preheating, using higher current

settings, using larger electrodes sizes, short runs for larger electrode deposits or tempering in a furnace.

Manganese Steels

The effect on manganese steel of slow cooling from high temperatures is to embrittle it. For this reason it is

absolutely essential to keep manganese steel cool during welding by quenching after each weld or skip welding

to distribute the heat.

Cast Iron

Most types of cast iron, except white iron, are weldable. White iron, because of its extreme brittleness, generally

cracks when attempts are made to weld it. Trouble may also be experienced when welding white-heart

malleable, due to the porosity caused by gas held in this type of iron.