Auto-cut 300 xt, Power supply status codes group 1, process codes – Tweco 300 XT Auto-Cut 400V User Manual

Page 122

AUTO-CUT 300 XT

A-�0

APPENDIX

Manual 0-5290

Power Supply Status Codes

Group 1, Process Codes

101

Plasma Enable Is Disabled

Code 101 is activated by either an open circuit between TB1-1 & 2 on CCM I/O PCB or Plasma Enable switched

off on the GCM 2010 or on the TSC 3000. TB1-1 & 2 comes from the factory with a jumper installed. An in-

staller may remove the jumper and connect a separate Plasma Enable switch or use the Plasma Enable wires

included in the 37 pin CNC cable used with the Ultra-Cut XT & Auto-Cut 300XT. The Auto-Cut 200XT which

uses a 14 pin CNC does not have the Plasma Enable in the cable. These may be used to connect to the cutting

table E-Stop switch. In either case the jumper would be removed from TB1-1 & 2. 101 is not a latched code, it

clears as soon as the condition is fixed.

Causes for 101 code other than one of the Enable switches being off (see detailed descriptions below):

• Gas Control Cable from J55 to gas control not connected.

• Ribbon cable from Relay board to I/O board not connected.

• CNC cable not connected (if using a Plasma Enable switch or output from the cutting table or robot).

• Defective Relay PCB

• Defective CCM I/O PCB

Special case: Display alternates between E101 and ----. This happens when there is both a missing phase and

Plasma enable is off. It is probably a bug in the code, it should be showing E101 & E201 (missing phase code).

We will likely fix this in a later code release but be aware of it for now.

External or CNC Plasma Enable D2, CNC PLASMA ENABLE LED, is not on.

• LED D2 on the CCM will be on if this input is satisfied either with the jumper on TB1- 1 & 2 or an external

or CNC switch. If the jumper is in place and the LED is not on, the CCM is most likely defective.

• If the jumper at CCM TB1-1 & 2 has been removed to use an external switch, install a jumper as a test. If

D2 illuminates the problem is with the switch or it’s wiring.

• If Plasma Enable is wired through the CNC cable remove the cable and jumper J15 pins 25 & 26. If D2

still not on there may be a problem in the wiring inside the power supply.

Plasma Enable from Gas Control or TSC 3000

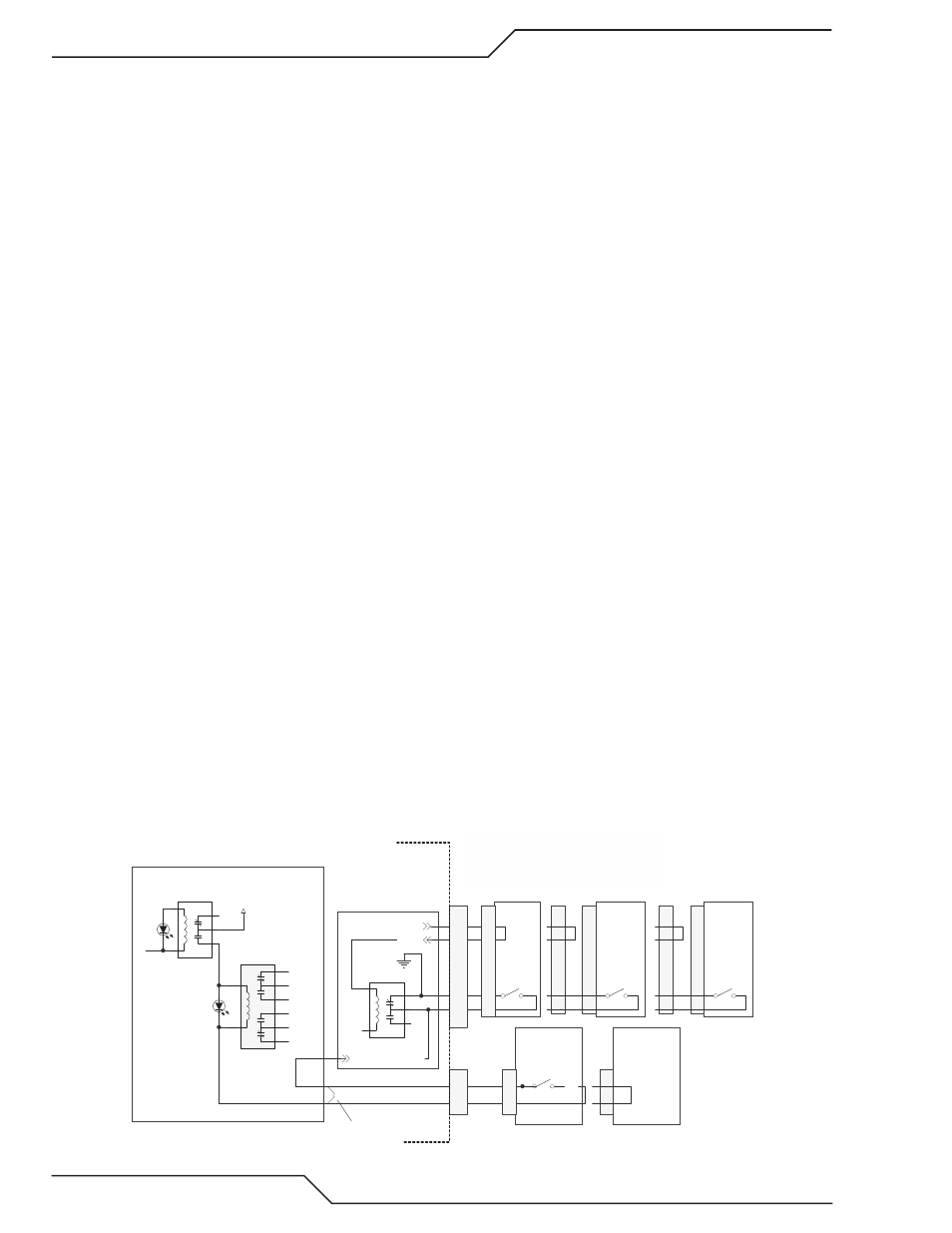

If the External or CNC Plasma Enable is satisfied, D2 is on, a relay K7 on the CCM I/O PCB energizes supply-

ing +15V to another relay K1 on the I/O board. An active low signal, /Plasma Enable-HMI, comes from TSC

3000 Plasma Enable switch via the Relay PCB or if TSC 3000 is not installed the signal originates on the Relay

PCB. This signal applies ground to the K1 relay energizing it and lighting the LED, D3 on the I/O board. K1’s

contacts go back to the Relay board and the Gas control connector J55 to allow turning on relays and solenoids

on those devices. The AC 200 XT does not use the separate Gas Control or the TSC 3000.

Art # 12304

1

5

3

2

4

K7

1

8

4

2

6

7

3

5

PLASMA ENABLE

K1

/PLASMA ENABLE - HMI

GND

24 VAC

24 VAC

TSC 3000

RELAY PCB

1

5

3

2

4

PLASMA ENABLE - CNC

K6

+15VDC

GREEN

D3

PS_ENABLE

To

Relay

PCB

To Gas

Control

CCM I/O PCB

GREEN

D2

Plasma Enable SW

GCM 2010

(or jumper in

other gas controls)

-1

-3

-5

-6

J54

J55

XT Power Supply

Simplified schematic, all connectors are not shown.

Refer to unit schematics for details.

J61

J56

-1

-2

Jumper in

AC 200 XT

J26-6

J26-7

GCM 1000 XT

J56

J54

When the circuit between J54-1 & 3 is closed (jumper,

etc.) K7 is energized and requires a Plasma Enable SW

or equivlant to enable the plasma.

With J54-1 & 3 open K7 is denergized and it's NC

contacts complete the Plasma Enable-HMI circuit.

-1

-2

-2

-1

-5

-6

-3

-1

-5

-6

-3

-1

(AC 300 XT

DMC 3000)

J25

-15

-22

J30

-20

-25

Plasma

Enable

SW

iCNC

XT 2 &

XT 242

J54

-5

-6

-3

-1

iCNC

XT 211

HMI PLASMA

ENABLE BYPASS