04 options and accessories, 05 introduction to plasma – Tweco PCM-62 Machine Torch User Manual

Page 14

INTRODUCTION

2-2

Manual 0-2817

B. Torch Leads Lengths

Hand Torch: 20 ft (6.1 m) or 50 ft (15.2 m)

Machine Torch: 25 ft (7.6 m) or 50 ft (15.2 m)

C. Torch Parts

Gas Distributor, Electrode, Tip, Shield Cup

D. Parts - In - Place (PIP)

Torch Head has built - in contacts

12vdc circuit rating.

E. Type of Cooling

Combination of ambient air and gas stream through

torch

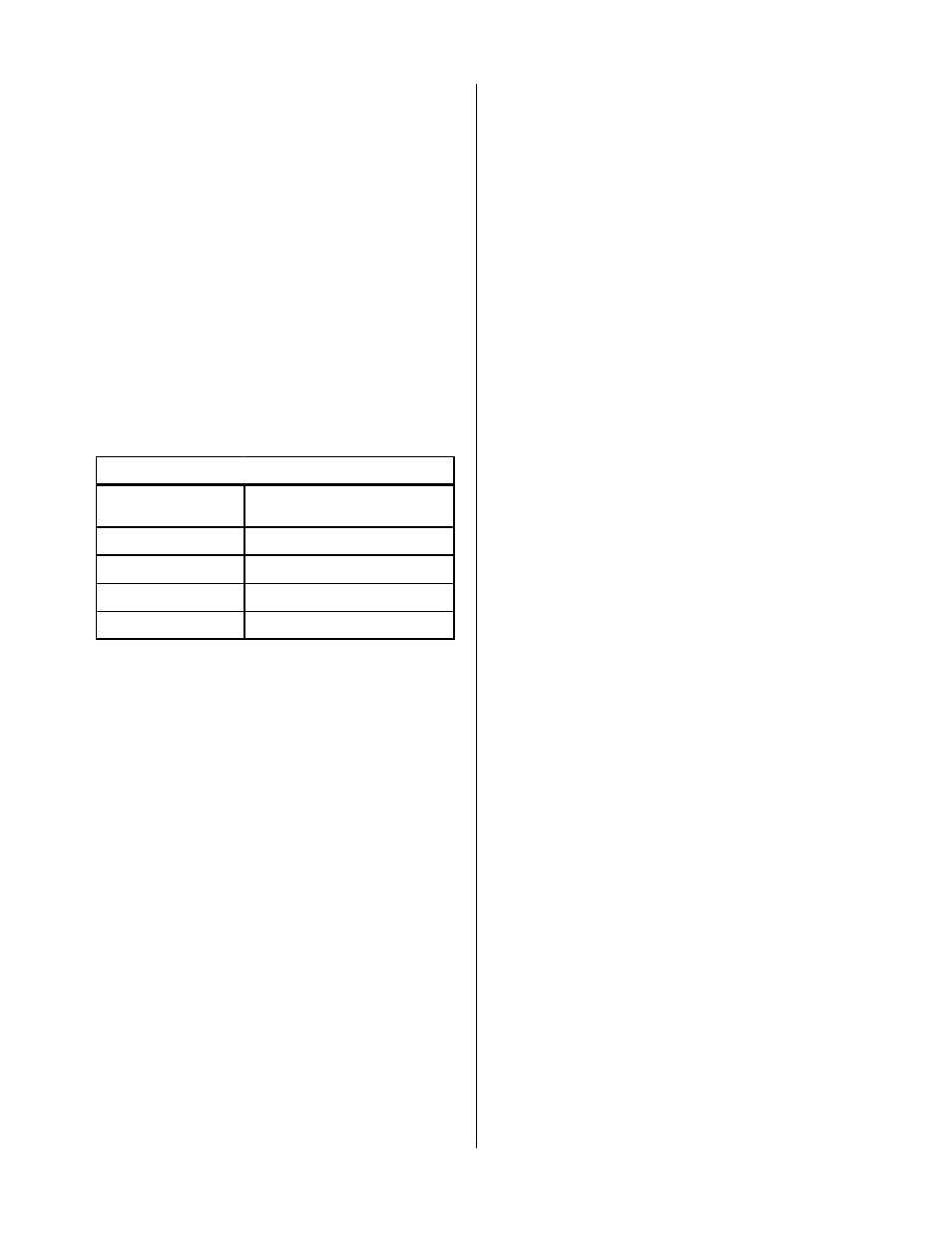

F. Torch Ratings

Ambient

Temperature

104° F

(40° C)

Duty Cycle

100% @ 60 Amps @ 375 scfh

Maximum Current

60 Amps

Voltage (V

peak

)

500V

Arc Striking Voltage

12 kV

Torch Ratings

G. Plasma Power Supply Used With

• CutMaster 50

• PakMaster 50XL Plus

• CE CutMaster 50

• CE PakMaster 50XL Plus

H. Direct Contact Hazard

For exposed tip the recommended standoff is 1/8" -

3/8" or 3.2 - 9.5 mm.

2.04 Options And Accessories

These items can be used to customize a standard system

for a particular application or to further enhance perfor-

mance (refer to Section 6 for ordering information).

• Spare Parts Kits - Various kits containing replace-

ment front - end torch parts for various applica-

tions.

• Circle Cutting Guide Kit - Easy add - on attach-

ments to allow for straight line, circle cutting, and

beveling with a hand torch. The guide fits both

the 70° and 90° hand torches.

• Standoff Cutting Guide - Simple push - on attach-

ment to allow for torch dragging without risk of

touching tip to workpiece.

• 1-3/8" Metal Mounting Tube with Rack & Pinion

Assembly

• Pinion Assembly - For machine torches.

• Computer Control (CNC) Cable 25 ft (7.6 m) or

50 ft (15.2 m)

• Hand Pendant Control Assembly - Used for ma-

chine applications. Hand Pendant Control has 20

ft. (6.1 m) cable which provides ON / OFF sig-

nals to the Power Supply.

• Extension Cable for Hand Pendant Control - 25 ft

(7.6 m) cable which can be added to the Hand

Pendant Control cable to provide a total control

cable length of 50 ft (15.2 m).

2.05 Introduction to Plasma

A. Plasma Gas Flow

Plasma is a gas which has been heated to an extremely

high temperature and ionized so that it becomes elec-

trically conductive. The plasma arc cutting and goug-

ing process use this plasma to transfer an electrical

arc to the workpiece. The metal to be cut or removed

is melted by the heat of the arc and then blown away.

While the goal of plasma arc cutting is separation of

the material, plasma arc gouging is used to remove

metals to a controlled depth and width.

In a Plasma Cutting Torch a cool gas enters Zone B

(refer to Figure 2-2), where a pilot arc between the

electrode and the torch tip heats and ionizes the gas.

The main cutting arc then transfers to the workpiece

through the column of plasma gas in Zone C.